Basic Features and Connection Advantages of Press-fit Connectors

As we all know, the traditional connector assembly process is complex, the cost is relatively high, and the performance testing is not quite stable, making the application more limited. With the rapid development of telecommunication, automotive, and industrial fields, higher requirements have been placed on existing connectors, and the emergence of press-fit terminal connectors meets this development demand. We are seeing these products rapidly being integrated into the fields of communication, vehicle electronics, and others. The following article briefly introduces the basic features and connection advantages of Press-fit Connectors.

Basic Structure of Press-fit Connectors

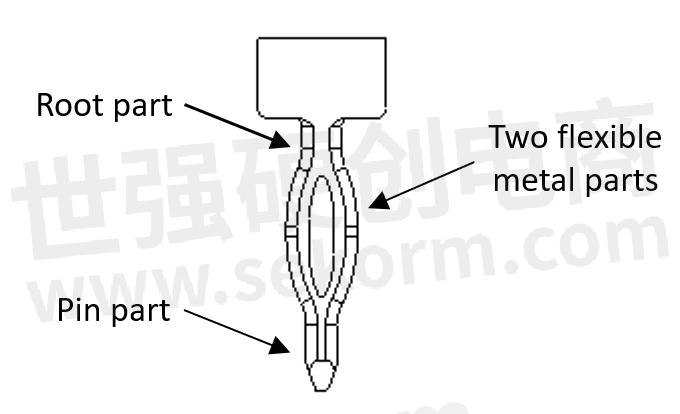

A press-fit connector is a connector with fish-eye-like terminals. It is called a fish-eye terminal because it contains a structure that resembles a fish eye. This particular connector consists of a root part, two flexible metal parts, and a pin part at the end (as shown in Figure 1). The flexible part of the press-fit is in the shape of two circular arcs which come together at a point. The two flexible parts of the metal are arranged opposite to each other which creates a fish-eye-like hole. During installation, the flexible part is prone to elastic contraction due to being squeezed by the female side of the connector, so that it fits perfectly with the conductive holes onto the circuit board.

Figure 1:Basic Structure of Press-fit Connectors

Assembly Principle of Fish-eye Terminals

The assembly of the press-fit terminal depends on the elastic contraction of the two flexible parts by extrusion, so that the press-fit terminal is smoothly inserted into the conductive hole of the circuit board and cooperates with the conductive hole on the circuit board, so as to realize the connection between the press-fit terminal and the circuit board. The contact area between the press-fit terminal and the circuit board increases as well as the interaction force does, thereby reducing the contact resistance between the press-fit terminal and the circuit board, which reduces heat generation, making the press-fit terminal suitable for high current applications.

Figure 2: Electrical connection between the press-fit terminal and circuit board

Connection Advantages of press-fit terminals

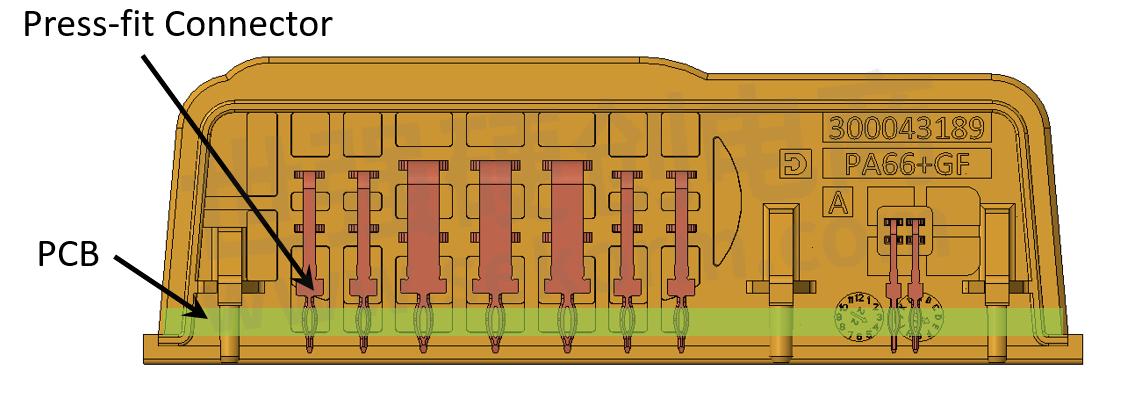

The combination of the press-fit crimp terminal and the PCB board (i.e. circuit board) is a connection method without the need for solder joints (as shown in Figure 3). Since this connection method does not require soldering, problems such as empty soldering and virtual soldering can be avoided, as well as the adverse reactions that occur when the main board passes through the high temperature soldering machine. This, overall, improves the quality of the product and creates a more environmentally friendly product. Furthermore, the electrical reliability of the solder-less connection is higher, which increases the service life of the connector. The crimping assembly method is also simpler and can be easily removed and replaced should there be any problem. If the connector is damaged, it can be directly removed from the PCB and replaced with a new one, which not only improves work efficiency but also saves costs.

Figure 3: Solder-less connection between press-fit terminals and a PCB board

Common Specifications of Press-fit Terminals

After the press-fit terminal is assembled and pressed, it relies on the insertion and withdrawal force of hard interference to meet the needs of its use and to make the quick replacement of the connector possible, so the size requirement of the fish-eye part is super high. For materials with different plating thicknesses, the size of the fish-eye is different, so that the corresponding insertion force and withdrawal force can be matched to meet the requirements of use in different environments. Figure 4 shows several commonly used specifications:

Figure 4: Common Specifications of Press-fit Terminals

GREENCONN has been committed to the field of connector R&D and manufacturing for 25 years, and has developed a variety of press-fit terminals with different pitch, pin number, mating orientation as well as other specifications for customized connection solutions to meet the different needs of customers in automotive, industrial, consumer and other fields.

- +1 Like

- Add to Favorites

Recommend

- Smiths Interconnect Launches Press-Fit cPCI Connector Series to Enhance Efficiency, and Reduce Costs

- ELETE Press-fit With High Electrical Reliability, Suitable For Communications, Automotive Electronics, Medical And Other Industries

- Mitsumi MMR920 Pressure Sensor is Ideal for Water Level Measurement in a Smart Water Bottle Due to Its Small Size, Low-cost, and Liquid Compatibility

- How Does Press-fit Technology Elevate IGBT Production?

- Xiangru Electronic XRACM-7060F-501 Common Mode Choke Integrates Miniaturization, High Reliability and Excellent EMI Suppression Ability

- Vincotech’s Power Modules‘ Current Carrying Capability of a Standard Solder Able Pin and a Press-fit Pin

- Nextron Launched LPM3 Mini Press-fit Machine, Retaining the Widely Praised Advantages of LPM3 with a Smaller Size and Lighter Weight

- LINK-PP‘s Cutting-Edge 400G Transceiver: Supports an Impressive Data Rate of 400Gbps, Elevating Network Performance

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.