Vincotech’s Power Modules‘ Current Carrying Capability of a Standard Solder Able Pin and a Press-fit Pin

1 Abstract

This application note investigates the current carrying capability of a standard solder able pin and a Press-fit pin for Vincotech’s power modules. The measurements are carried out on an application board with boundary conditions comparable to real application.

2 Introduction

The Press-fit pin technology is a solder-less connection method, which ensures reliable mechanical and electrical contact. The Press-fit pin design contain a mechanism that allows plastic deformation when the pin enters the hole and creates a highly reliable, well accepted, gas tight cold-welded connection. The Press-fit pin was developed as a one-to-one replacement for the solder pin. This means that all Vincotech power modules can easily be equipped with the Press-fit pin and do not require a PCB layout change by the customer.

3 Current carrying capability of pins

The current carrying capability of Press-fit pins was tested against standard soldered pins. As it was mentioned earlier one of the design targets was to create the possibility that the soldered and the Press-fit modules should be replaceable one to one. It requires that the current carrying capability of the Press-fit version is similar to the standard pin.

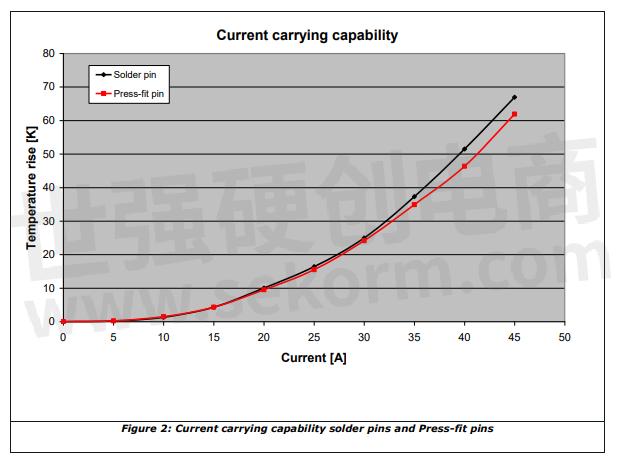

Different track widths were tested to get a good comparison. The Figure 1 illustrates the test board used for the measurements, and the temperature distribution of a pin. The PCB consists of 4 layers. The two outer layers have 105 µm copper and the two inner layers which are placed only around the holes have 35 µm copper thickness. The surface finish of the FR4 PCB is immersion tin. The copper thickness of the through holes is 25 µm. Figure 2 shows the current carrying capability of one pin inserted or soldered in a 250 mil wide track. The modules were mounted to a heat sink with thermal grease P12 from Wacker. The heat sink had a temperature of approx. 30 °C.

The measurement was done with the help of an infrared camera and the temperature of the hottest point was defined. See Figure 2. The results show a very similar temperature rise for both types of pins at a given current. Other parameters, like ambient temperature, the number and thickness of copper layers can influence the current carrying capability of the pins, thus in some cases it makes sense to test it for the specific application.

4 Conclusion

Solder and press-fit pin show very similar temperature rise at a given current and have thus the same current carrying capability.

- +1 Like

- Add to Favorites

Recommend

- Real Chip-level Multi Sourcing - The Multi-sourced Power Modules Featuring IGBT M7 for Motion Control Applications

- Faster, Cooler & More Efficient DC EV Charging:Vincotech’s FlowANPFC and Flow3xANPFC Power Modules

- Choose High-quality Power Modules to Extend the Life of Your Equipment

- Highly Integrated and Ultra Compact Power Modules for Embedded Drive Applications

- Zettler Magnetics Expands High Performance (HP) Series and Lower Cost (ZP) Series of Power Modules

- ZETTLER Introduces HPI10 Series of Plug & Play 10W Power Modules Supporting Input from 90-528VAC

- Bare Die SiC from ROHM Chosen by Apex Microtechnology for Newest Line of Power Modules, Saving Space and Increasing Performance

- Power Modules: Provide Reliable Power for Your Devices

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.