Rogers curamik® Ceramic Substrates offer superior thermal properties and have applications in many of the world‘s most advanced electronic systems

Ceramic substrates are materials typically used in Power Modules with unique thermal, mechanical and electrical properties that make them ideal for demanding power electronics applications. These substrates enable the electrical function of a system providing mechanical stability and a superior thermal performance to meet the requirements of each unique design.

Ceramic Substrate Advantages

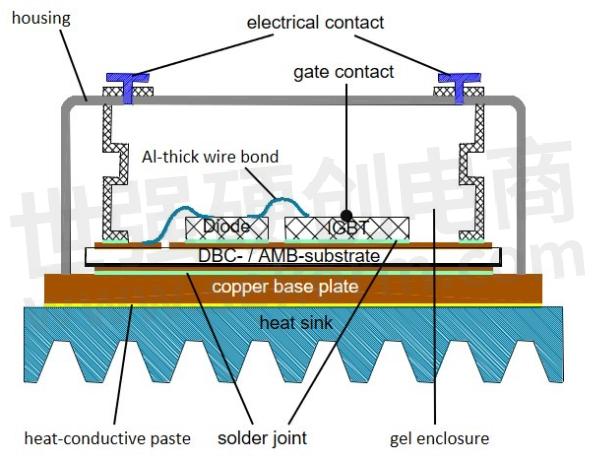

Ceramic substrates are usually found within the copper/metal layers of a Power Module as part of a power electronics circuit. They assist in the function similar like a PCB, allowing it to best perform its desired purpose. The diagram below shows a typical representation of the location and function of the substrate.

There are many advantages in choosing a ceramic substrate over other substrates based on metal or plastic. ROGERS curamik® Ceramic Substrates offer superior thermal properties such as high-heat conductivity, extended heat capacity and enhanced thermal spreading. Their low coefficient of thermal expansion enables a range of mechanical benefits making them suitable for the most critical applications. On top of this, they provide a rugged electrical insulation protecting the users from the electrical system.

Types of Ceramic Substrates

Choosing the right substrate for your application is a key factor in optimizing the performance of your system. Our Advanced Electronics Solutions team is available to help you select the ideal substrate and find the best trade off among mechanical parameters, thermal performance and cost.

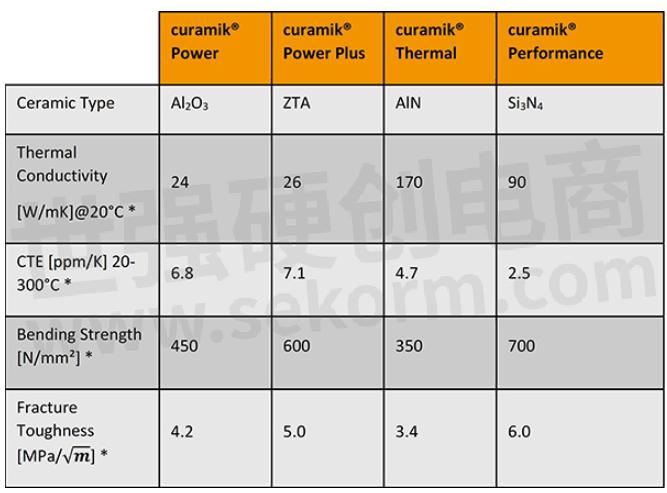

Rogers' curamik® portfolio includes curamik® Power, curamik® Power Plus, curamik® Thermal and curamik® Performance substrates.

*Values are valid for bare ceramics

Applications for Rogers Substrates

Ceramic substrates have applications in many of the world's most advanced electronic systems, including the expanding renewable energy and vehicle electrification industries. Below are just a few notable markets and applications that can benefit from the implementation of curamik® substrates.

Electric and Hybrid Vehicles and Vehicle Electrification

Many upgrades in automotive comfort and safety features are driven by advances in vehicle electrification. Automakers are also notably interested in electrifying cars’ powertrains from mild hybrid into full electric vehicles to meet growing market demand for low emissions vehicles.

More electrification requires more power. High-current, high-voltage solutions are needed to drive all-new electric functionalities within strict mechanical boundaries. Because of their superior qualities, Rogers substrates are found in market applications including electric power steering, electrical braking systems, integrated starter alternators, diesel and water-pump controls, motor and engine controls, and converters/inverters for HEV/ EV, LED lighting and alternators.

Renewable Energy

Rogers substrates can be found in diverse applications throughout the renewable energy industry, including technologies used for wind and solar energy production and storage, such as inverters for photovoltaic solar (PV) and wind as well as concentrators for concentrator photovoltaics (CPV).

Industrial

Our curamik® substrates have shown excellent performance in broad applications under the umbrella of the general industry. Some industrial applications for ceramic substrates include pump controls, variable frequency drives, traction drives, power supplies, Peltier coolers, customized motor controls, standardized semiconductor modules with chips on board, DC/DC converters and AC/DC converters.

Major Home Appliances

Demand for large electrical home appliances (also known as white goods) is influenced by customer preference for energy efficiency, noise control, maintenance accessibly and safety features. Rogers substrates have a number of applications in major home appliances, including the intelligent power modules that drive appliance motors.

Contact Us About curamik® Metalized Ceramic Substrates

With almost 40 years of expertise in joining metal and ceramic technologies, Rogers is a trusted, leading manufacturer of Direct Bonded Copper (DBC) and Active Metal Brazing (AMB) substrates under the curamik® brand.

Rogers offers full access to our team to customize a product design to match your design's unique needs. Contact us for additional information or assistance on your project.

- +1 Like

- Add to Favorites

Recommend

- Rogers Corporation’s Power Electronics Solutions Group to Showcase curamik® Ceramic Substrates & ROLINX® Eco Busbars at the PCIM 2023

- A Historic Milestone for Rogers Germany GmbH – Groundbreaking for Production Expansion in Eschenbach

- Rogers Corporation’s Curamik® Ceramic Substrates, Low Inductive ROLINX® Laminated Busbars Power Renewable Energy Sources

- Rogers Announces Acquisition of Silicone Engineering

- Rogers Expands Capabilities and Services with New Application Laboratory

- Sekorm Became an Authorized Distributor of Rogers

- Rogers‘ Micro Channel Coolers (MCC) in High Performance Computing (HPC) Applications

- Rogers Announces Termination of Merger Agreement with DuPont

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.