Geehy APM32F407 Low-Voltage Servo Drive Solution that Can Operate Reliably in A Variety of Industrial Applications

Low-voltage servo drives are essential components in modern industrial motion control systems. They accurately control servo motors through torque, speed, and position. Low-voltage servo drives are widely used in small installation spaces with high electrical safety requirements, such as low-voltage power supplies, positioning control systems, and mobile power supply environments in automation applications. These include intelligent logistics AGV drive systems, wind turbines, robotics, production line conveyors, channel gate control, gripping and handling mechanical devices, and engraving machines.

The MCU, as the brain in motor drive system designs, plays a pivotal role in determining the overall performance and design of the system.

Geehy APM32F407 Low Voltage Servo Drive Solution

The APM32F407 low-voltage servo drive solution is a high-performance and compact solution that can operate reliably in a variety of industrial applications. The main control MCU supports integrated design for servo motor systems and provides a wide range of peripheral interfaces.

Key Features of APM32F407 Low-Voltage Servo Drive Solution

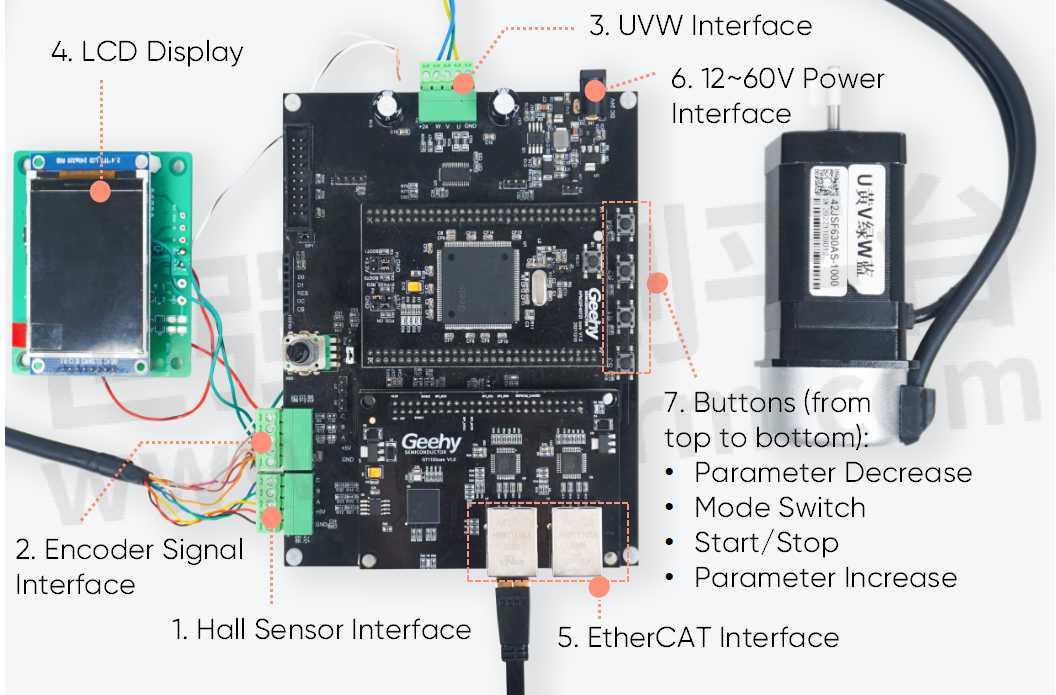

• Speed control mode: Precise speed control with button setting and stable speed at the target value.

• Position control mode: Accurate positioning with button setting and precise stop at the desired position.

• Encoder interface: Seamless connection with incremental encoders for high-precision control.

• EtherCAT module: EtherCAT communication and complex motion control in collaboration with PLC, PC, and EC.

• Human-machine interaction: Intuitive visibility of target speed/position, actual speed/position, operation mode, and system status on LCD screen.

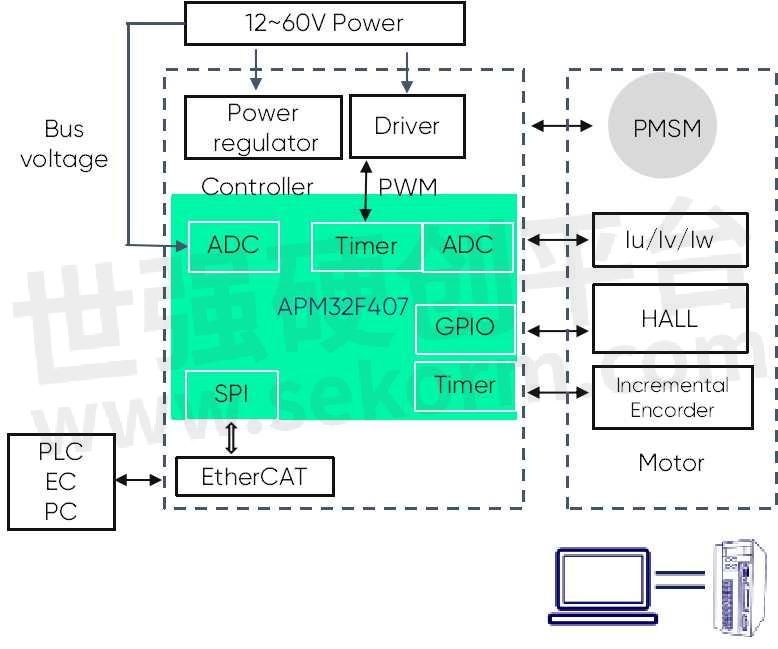

APM32F407 Low-Voltage Servo Drive Solution Block Diagram

Advantages of APM32F407 MCU

Excellent Computing Power

The MCU features the Arm® Cortex®-M4F core, capable of operating at frequencies up to 240MHz, supporting single-precision FPU and enhanced DSP processing instructions. It meets the control requirements of typical servo control systems with a carrier frequency of 16K and one current loop per carrier.

Rich On-Chip Resources

Ample storage capacity: With up to 1MB of Flash and 192+4KB of SRAM. Optional it supports expandable internal SDRAM up to 2MB and external memory expansion.

Efficient communication: The built-in eMMC interface facilitates seamless communication with peripheral FPGA.

CAN Bus communication: The built-in CAN interface enables the realization of the CANopen bus protocol, facilitating communication with PLCs and other main stations.

High-speed SPI interface: With a maximum communication speed of 42Mbit/s, the built-in SPI interface ensures swift access to EtherCAT chips and enables EtherCAT bus communication.

To meet the connection and application requirements of various peripheral devices in servo control systems, the MCU enables integration with motors, drivers, and reducers. This integration leads to improved power density compared to discrete designs, optimizing the overall system performance.

High-Performance ADC

With three 12-bit independent ADCs with sampling rates up to 2.5MSPs, the MCU accurately monitors motor current and bus voltage, enabling precise closed-loop control in motor applications.

Geehy offers comprehensive software and hardware technical support, along with demo boards, to help developers create low-voltage servo drives. The module operates as follows: The high-performance APM32F407 MCU serves as the main control, generating three sets of complementary PWM signals to control PMSM motor rotation. Three independent ADCs are used to sample motor current and bus voltage. The general timer's encoder mode captures pulse signals from incremental encoders. Through the current loop, speed loop, and position loop control, the motor achieves stable speed and precise position control. EtherCAT bus communication is realized via SPI access to the EtherCAT slave chip.

APM32F407 Low-Voltage Servo Drive Solution Image

Specifications of APM32F407 Low-Voltage Servo Drive Solution

✓ Two Control Modes

Speed mode: Set the target speed, and the motor rotates at the set speed.

Position mode: Set the rotation angle, and the motor stops at the set position.

✓ Control Mode

Dual closed-loop control (speed mode)

Triple closed-loop control (position mode)

PWM Frequency

10KHz

Motor Speed

-3000~3000rpm (4 poles)

Position Setting Range

0~36000°

With an extensive MCU product line, an experienced design team, and prompt technical support, Geehy caters to diverse motor drive needs across consumer and industrial applications and maintains strong partnerships with multiple terminal manufacturers. As motor product intelligence advances and application areas expand, Geehy remains committed to innovative breakthroughs in the product line layout, functionality, and performance.

- +1 Like

- Add to Favorites

Recommend

- Geehy APM32F407 Industrial-grade MCU Used for Power Optimizer Solution Safeguards PV Power Generation Efficiency

- Geehy APM32F407 Industrial HMI Solution Enhances Interactive Experience

- Geehy APM32F407 AC Charging Station Solution Promotes the Large-scale Deployment of “Dual Carbon“ Goals

- PEmicro Fully Supports Geehy APM32 Series MCUs

- Geehy APM32F407 MCU with A Maximum Frequency of 168MHz Used for Communication Power Solution

- Geehy and SEGGER Partner to Fully Support the APM32 Series industrial & automotive-grade MCUs

- Geehy Launches High Performance & High Security APM32F405/415 Series Industrial-grade MCUs

- Geehy Showcased a Reliable 32-Bit APM32 MCU Solution at Embedded World 2023

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.