ROHM‘s Latest Technology Towards Achieving a Sustainable Society: Nano Energy™ Ultra-Low Current Consumption Technology

Recent years have seen the increased proliferation of battery-driven electronic devices, including wearables and IoT, along with portables such as smartphones. For the electronic components that comprise these sets, miniaturization is required to improve design and secure space for new functions, while lower power consumption is needed to prolong battery life. Configuration typically consists of a CPU in charge of overall control, sensor(s) for acquiring necessary environmental data, and wireless devices to provide communication. Optimized processing of this information makes it possible to achieve a variety of functions. In addition to these, a power supply IC is used to provide stable voltage from the battery to operate all of the various components. And since electronic devices need to immediately respond to external signals even during standby, it is necessary to include a function for continuous monitoring. To supply voltage to this function, the power supply IC must continuously operate. Consequently, the current consumption of the power IC must be reduced in order to prolong battery life. ROHM has developed a power supply IC that meets market needs by leveraging a vertically integrated production system along with analog design technology and power processes. These days, there is an increasing demand to achieve a sustainable society. In fact, '10-year drive on a coin battery’ has become a key phrase in the IoT and wearable fields. To respond to market needs, ROHM leveraged ultra-low current consumption technology, dubbed Nano Energy™, to develop an ultra-low power supply IC that makes it possible to achieve continuous 10-year operation on a single coin battery.

ROHM's BD70522GUL switching regulator utilizes Nano Energy™ technology to deliver an ultralow current consumption of just 180nA (Fig. 2). Next, ROHM will introduce Nano Energy™ technology.

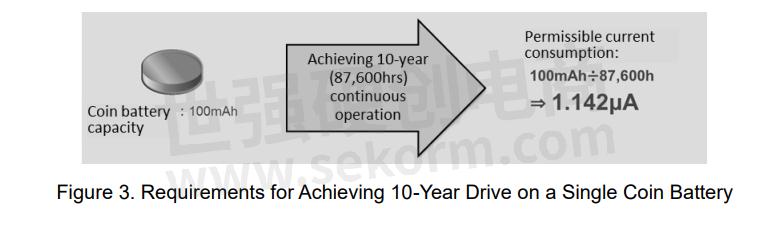

Achieving 10-year drive on a single coin battery

The most well-known example of a coin battery is the CR2032. Battery capacity is typically 220mAh, with specifications common among different manufacturers. To achieve a continuous drive time of 10 years on a coin battery, it is first necessary to calculate the current consumption required for the power supply IC. However, it must be noted that not all of the battery capacity will be consumed by the power supply IC. Many calculations assume a power supply IC consumption of 100mA. ICC (Current Consumption)=100mAh (Battery Capacity)÷87,600h (10 years)≒1uA (Fig. 3) This 1uA is the average current consumption during maximum operation that is allowed to flow in the power supply IC. In other words, current consumption of the power supply IC must be on the order of nA. Limiting IC current consumption will make it possible to expand functionality while maintaining continuous operation without increasing battery capacity. The BD70522GUL meets this need with a current consumption of only 180nA.

Technical issues resulting from reducing current consumption

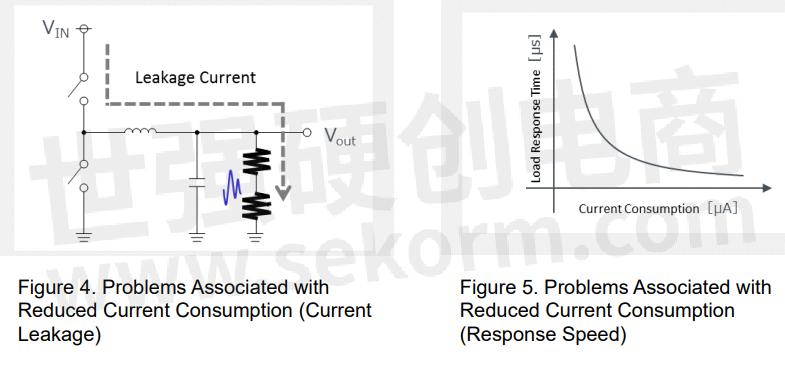

The easiest way to reduce current consumption in power supply ICs is to increase the internal resistance. However, simply increasing the resistance can cause a number of problems.

• Larger circuit area

• Increased effects against element leakage current

• Higher sensitivity to external noise due to larger impedance

• Reduced response speed of the analog circuit

Larger circuit area refers to the increase in the area of the resistance component following the increase in resistance.

Increased effects against element leakage current relates to problems with the MOSFETs that make up the power supply IC. A constant leakage current flows even when the transistor is in the OFF state. This leakage current occurs in the internal circuit and output stage. As an example, although the leakage current flowing into the feedback resistor (Fig. 4) is sufficiently small so as to be considered negligible with respect to the steady-state current (=output voltage÷feedback resistance) resulting from the output voltage and conventional resistance value, increasing the resistance reduces the steady-state current, so the effects of the leakage current cannot be ignored.

Higher sensitivity to external noise due to larger impedance assumes a pi-type filter connected by resistor (for simplicity's sake). When a voltage is applied to one end and noise enters the other, the time constant until the voltage of the noisy terminal settles to the original voltage is determined by the RC of the pi-type filter. As this resistance increases the time constant also increases, and the time until a stable state is reached becomes longer. The response speed of the analog circuit is determined by a number of factors, but let us consider the case of charging the capacitor. The time it takes for the charge to reach a certain operating voltage is the response speed, which is proportional to the charge current and consequently degrades as the current consumption increases.

Overcoming challenges with element technology and the resulting characteristics

In response to the various issues mentioned above, ROHM developed Nano Energy™ technology that combines analog circuit design, processes, and layout with a vertically integrated production system. This fusion has allowed ROHM to achieve optimized countermeasures for a variety of challenges. Here ROHM will introduce 2 element technologies and their results as an example of circuit design technology for Nano Energy™ used in the BD70522GUL.

• Reducing current consumption in the reference voltage and control monitoring blocks

• Overcoming the trade-off between high accuracy, fast response, and low current consumption in the control monitoring block

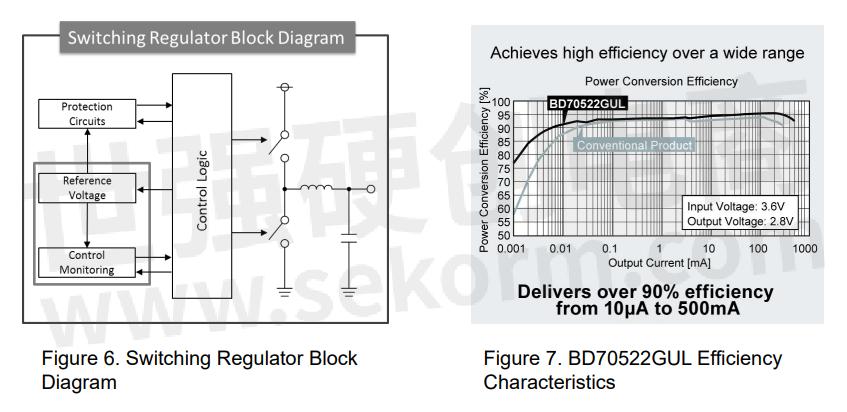

The BD70522GUL is a buck switching regulator(step-down switching regulator) . In a switching regulator, switching to intermittent operation when the output current (load) becomes smaller than a certain value makes it possible to reduce current consumption while maintaining the output voltage. In many applications where Nano Energy™ is required, intermittent operation is expected to prolong operating time. For the BD70522GUL, ROHM conducted a thorough analysis of the current during intermittent operation and implemented a reduction based on these results.

First, from the analysis results ROHM narrowed down the primary factors of current consumption to two areas, the reference voltage and control monitoring blocks (Fig. 6). Next,ROHM applied an optimized reduction method that allowed us to reduce current consumption in each block by 100x vs conventional products. As a result, efficiency, which is the most important characteristic of power supply ICs, was increased to over 90% at a load current of 10uA during standby of the subsequent stage (Fig. 7). What's more, these characteristics can be maintained over a wide range up to a load current of 500mA.

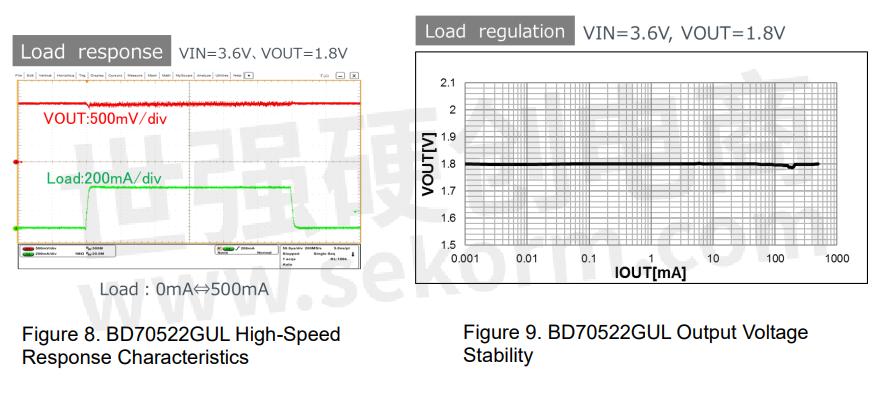

Next ROHM will describe the technology for overcoming the trade-off in the control monitoring block. As ROHM mentioned previously, when ROHM reduce the current consumption in the control monitoring block the response speed degrades. There is also another important circuit characteristic determined by the control monitoring block. Namely, stable output voltage. In the circuit configuration of a conventional control monitoring circuit, it is impossible to simultaneously achieve fast response with low current consumption and high accuracy. In contrast, the BD70522GUL utilizes Nano Energy™, developed after conducting a thorough review of the circuit configuration, to achieve all 3 characteristics. ROHM was able to deliver the ultra-low no-load current consumption along with high-speed response during load fluctuations (load response) and stable output voltage (load regulation) over the entire load range (Figs. 8, 9).

Nano Energy™ expands the range of applications Nano Energy™ is expected to be an extremely effective technology for reducing current consumption, which is a constant theme in all applications requiring power supply. As mentioned in the beginning, this technology is ideal for sets demanding long standby state along with fast response during operation. Suitable applications include security and portable devices that operate on li-ion and coin batteries. And in recent years, the accelerating digitization of vehicles is spurring adoption of this technology in automotive systems. ROHM's power supply IC lineup includes not only switching regulators, but LDO (Linear Drop Out) regulators as well. ROHM has already started development of LDOs that incorporate Nano Energy™ technology, and will continue to propose solutions that provide greater space savings with lower noise in order to contribute to a sustainable society. (Fig. 10)

Summary

Nano Energy™ technology developed by ROHM is an ultra-low current consumption technology that dramatically reduces power consumption of the power supply IC. As a result, the BD70522GUL equipped with Nano Energy™ technology delivers a ultra-low current consumption of just 180nA. And in response to the trade-off caused by reducing power consumption, Nano Energy™ technology allows the BD70522GUL to achieve simultaneously fast response, stable output voltage, and ultra-low current consumption. This allows us to propose solutions for a broader range of applications, including automotive systems that are seeing increased digitization and portables that demand 10-year drive on a single coin battery. ROHM currently offers 2 advanced power supply IC technologies, Nano Energy™ and Nano Pulse Control™*1 . These technologies are not only effective for specific markets, but are also ideal for areas pursuing greater performance.

- +1 Like

- Add to Favorites

Recommend

- ROHM‘s New Ultra-High Efficiency Battery Management Solution Evaluation Board for Thin, Compact IoT Devices

- Silicon Carbide cooperation between SEMIKRON and ROHM Semiconductor: ROHM’s SiC technology empowers SEMIKRON’s eMPack® for the next generation of electric vehicles

- Notice of Integration of ROHM Three Sales Companies in China

- Continental acknowledges ROHM Semiconductor with the “Supplier of the Year 2022 Award“

- ROHM Online Distributor China | Sekorm

- ROHM‘s Nano Energy™ and LAPIS Technology‘s Charge Control IC Help Maxell Energy Harvesting-compatible Evaluation Kit

- ROHM SiC MOSFETs Solve Design Challenges for Leading Solar Energy Company Midnite Solar

- Ultra-Low IQ PMIC from ROHM Selected to Power NXP iMX8M Nano for High Performance Embedded Artists Industrial Control Board

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.