Endurance, Latency, and Workload Considerations for Choosing Dashcam Memory Cards (Part 1)

As the resolution and development of dashcam or DVR evolve, merely looking for high-capacity storage is not enough. To record videos non-stop for thousands of hours without compromising data integrity, you will need high-endurance Memory Cards.

Challenges for dashcam storage

Recording Challenges

• Non-Stop Operation. Dashcams/DVRs typically operate for extended periods of time. Recording over and over again may cause NAND storage failure on video.

• Latency Under Different Temperature Profiles. Both extreme heat and cold environments can affect flash memory cells and the performance of the storage media.

• Harsh Operating Conditions. Environmental conditions of camera location contribute to flash degradation and can endanger the integrity of the data in it.

• Power Supply Instability. Any power flux or interruption may cause damage to the dashcam or storage device, thus corrupting data integrity.

What should we consider when choosing a memory card for recording?

1. Endurance Matters

The endless writing/rewriting of camera recording causes NAND flash cells on the storage media to wear out, leading to possible video corruption and rendering the stored data useless when it is needed most.

NAND P/E cycles may have a direct impact on storage lifetime. With different NAND architectures, endurance could have 2-3 times extension.

Evenly distributing erase counts to each block could extend the lifetime of the storage device on the recording media.

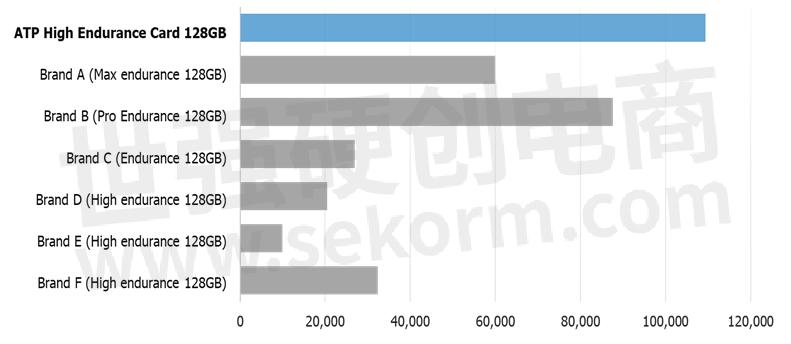

Endurance = Recording Hours = Capacity?

As demand for longer recording time increases, unsurprisingly, more and more high-capacity memory cards are successively being launched to fulfill the demands of the dashcam market. For example, when recording a 4K video (100Mbps), a 256GB memory card can store about 5 hours and 40 minutes before it is full and overwritten for a new recording.

Users may choose a super high-capacity memory card just for longer recording time but as usage time increases and with the non-stop writing and rewriting day by day on storage devices, a high-endurance memory card with a suitable warranty is the one that stands out and provides higher recording quality as well as better data integrity for long-term recording time.

Figure 1. Continuous recording hours with 128 GB memory card

Notes:

• Tested using 128GB ATP S650 TLC card based on 13Mbps (lowest bitrate of HD recording) in the best-case/ideal scenario, with no other influencing factors.

• Information sourced by ATP from publicly available data.

• To record new data, the oldest data will be overwritten when the card is full.

• 1Mbps=1,000,000bps

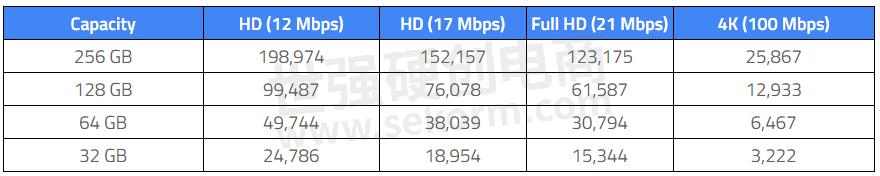

Table 1. Estimated non-stop recording hours with ATP high-endurance card

2. Low Latency: Fast Response is Critical

Users expect their systems to be ready with fast response for evidence recording. Taking the drive recorder as an example — after power on, the bootup time depends on the embedded memory, yet the time required to be ready for recording and succeeding programming depends on the external/removable storage, such as SD/microSD cards.

Figure 2: Drive recorder response time

High-endurance memory cards built for dashcam recording may save more than 50% time to be ready for recording than other commercial cards under different environmental conditions, which can effectively help the critical video being recorded.

Table 2: Maximum response time(s): fast response in any temperature scenario

Figure 3. It only takes 2.25 seconds to respond to the host and prepare for recording @-20oC

Notes:

The point represents 1 cycle within DVR: 2 mins. power on and 2 mins. power off.

The complete test duration is around 18 hours. We collect the latest 250 points (dirty state).

3. Workload Matters

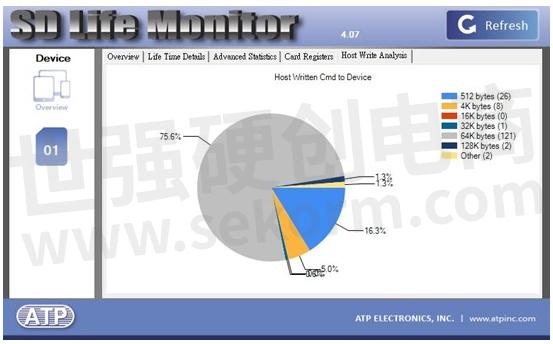

To understand the lifetime and quality of the recording, information from the host and memory storage may be a key indicator.

ATP SD Life Monitor tool can be applied for product development.

• Workload Inspection. On Windows, the ATP SD Life Monitor tool provides health status reports and card identification information. Furthermore, with an additional "Workload Inspection" pie chart, users can quickly check the write operation and file size by the host systems.

Considering the NAND flash page size and FW algorithm, ATP provides recommendations and more information for the host devices' program data based on the multiples of minimum data transfer size in the SD/microSD card datasheet.

Figure 4. ATP SD Life Monitor illustrates the example that the majority of file sizes written by the host device is 64 KB (121 times).

ATP Joint Validation Service with host workload inspection can provide customers comprehensive solutions on both hardware and software concerns.

• On Linux, customers can install the ATP SD Guardian tool that has a user-friendly interface for information display or refer to the ATP Command 56 guidelines, which can directly issue SD vendor commands for software integration.

ATP Electronics recently introduced its new 3D triple-level cell (TLC) S750/S650 Series High-Endurance SD and microSD memory cards built for continuous video recording. They meet the high endurance, low latency, and built-to-last data storage requirements of dashcams and digital video recorders (DVRs), as well as surveillance systems, autonomous vehicles, and other write-intensive applications.

- +1 Like

- Add to Favorites

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.

Recommend

Ensuring NAND Flash and Data Integrity of Dashcam Memory Cards (Part 2)

2022-09-02 - Technical Discussion In this article, ATP presents three most frequent causes of data corruption, their fixes, and an enhanced analysis approach based on NAND technology and user behaviours. New S650/S750 Series SD meet the high endurance, low latency, built-to-last data storage requirements of dashcams.

High-Endurance, Low-Latency SD/microSD Cards Built for Dashcams, DVRs Offer Over 109K Hours of Continuous Video Recording

2022-07-23 - New Product Introduction ATP Electronics introduces its new 3D TLC S750/S650 Series SD and microSD memory cards built for the rigors of non-stop video recording. They meet the high endurance, low latency, and built-to-last data storage requirements of dashcams and DVRs, and other write-intensive applications.

SD/SDHC/SDXC Card

2025年6月20日 - Datasheet

S800PI,S750PI / S750PC,S600SI / S600SC,S700PI / S700PC,S650SI / S650SC

查看更多版本ATP Introduces High-Endurance Video Recording, 512GB Max. Capacity Memory Cards for AI Surveillance Infrastructures

2024-03-27 - Product Introduction ATP Electronics introduces its new S650Si (TLC) and S750Pi (pSLC) Series SD and microSD memory cards built with 176-layer 3D NAND technology and low-density parity check (LDPC) controller. With expanded capacity offerings up to 512 GB and 5-year extended supply longevity support, the new memory cards are targeted for growing segments spurred by 5G, artificial intelligence (AI), and edge technologies.

A Tutorial Guide on Selecting the Right SD Card: SD Card Symbols, Classes, and Compatibility Deciphered

2022-12-01 - New Technology Information Article Here‘s a tutorial guide on selecting the right SD card: SD Card symbols, classes, and compatibility decipheredUser experience and the constant need for more efficient and cost-effective products continue to drive innovation of new technology and the evolution of SD standards.

microSD/microSDHC/microSDXC Card

2025/07/02 - Datasheet

S750PI/S750PC,S800PI,S600SI/S600SC,S700PI/S700PC,S650SI/S650SC

查看更多版本ATP 3D NAND-Based Memory Cards Meet Growing IoT /IIoT Storage Needs, with Industrial Temperature Ratings of -40℃ to 85℃

2023-11-24 - Manufacturer News ATP‘s industrial-grade SD and microSD cards based on 3D NAND technology meet the growing data storage needs of the IoT/IIoT. Thanks to these tiny and low-power yet powerful removable data collection solutions, gateways can store huge amounts of data closer to the source, providing local intelligence and ensuring Internet-independent operation even in the event of connection outages.

The Most Reliable Storage For Industries: Industrial SD H2-M

2021/11/28 - Datasheet

H2-M,INDUSTRIAL SD H2-M

查看更多版本ATP “Industrial Only” Memory Cards: Gateways to the Intelligent Edge in the Smart Factory

2022-11-03 - Manufacturer News ATP A1 cards use 3D MLC NAND flash for enhanced reliability and endurance and are best used in applications requiring exceptional levels of data integrity and responsiveness.

The Most Reliable Storage For Industries: Industrial SD H2-SL

2021/11/28 - Datasheet

H2-SL,INDUSTRIAL SD H2-SL

ATP Electronics Showcases the Smallest, Most Powerful, and Greenest AI Memory and Storage Solutions at COMPUTEX Taipei

2025-05-07 - Manufacturer News Featured extreme solutions for the “AI Next” generation include the 7.2 mm e.MMC in the world’s smallest package; industrial solid state drives (SSDs) with record-breaking, highest-endurance ratings; and, industrial enterprise storage optimized for the toughest edge AI demands. ATP also marks a significant milestone with the upcoming opening of its new smart manufacturing facility in Kaohsiung, Taiwan, underscoring the company’s commitment to eco-sustainability by using technology to reduce environmental impact.

ATP “Industrial Only“ Memory Cards Meet Healthcare Applications Demands

2023-10-28 - Application solution Article With ATP‘s nearly three decades of experience in offering industrial memory, storage solutions, and a one-stop shop to fulfill the demand for data storage in the medical industry, ATP can surely be an integral cogwheel to help shape and create a better world.

WHEN THE BIGGEST OR THE LATEST ISN'T ALWAYS THE BEST: LONG LIVE 2D STORAGE SOLUTIONS

092024 - Supplier and Product Introduction

Electronic Mall

Integrated Circuits

Discrete Components

Connectors & Structural Components

Assembly UnitModules & Accessories

Power Supplies & Power Modules

Electronic Materials

Instrumentation & Test Kit

Electrical Tools & Materials

Mechatronics

Processing & Customization