IoT and IIoT: Flash Storage, Sensors and Actuators in Cloud/Edge

Flash Storage in the IoT/IIoT Era

The Internet of Things (IoT) is not merely a buzzword. It is a phenomenon that is already permeating almost every area of our lives, changing the way we live and interact not only with one another but also with everything around us.

Stand-alone objects that were once isolated are now increasingly becoming interconnected in this expansive digital labyrinth. Researches estimate that in less than 2 years, billions of objects will be connected to one another.

IoT Enablers

These important components enable the IoT, allowing objects to connect to one another through networks using various wireless and/or wired technologies.

Figure 1. Sensors, Processors and Actuators allow IoT devices to gather, process and respond to data.

Figure 1. Sensors, Processors and Actuators allow IoT devices to gather, process and respond to data.

Common sensors include those that "sense" or detect temperature, presence/proximity, pressure, sound, water quality, humidity, chemicals, gas and smoke. Data from sensors are then sent to a processor or data center via wired/wireless networks or gateways for analysis and processing. A Processor analyzes the data, and then sends a command to an Actuator. The Actuator receives the command from the Processor and transforms the data into useful output.

Here is a simple example of a parking assistance system showing how these components work together

Ultrasonic sensors detect objects in the front and rear bumpers of your car while you attempt to park. The Processor analyzes and interprets the data (space is not enough or obstruction is present). It then alerts and sends a command to an Actuator. The Actuator then gives off audible warnings with continuous beeps.

Meantime, ground sensors detect which spaces are unoccupied. They send the information to the network where the information is processed, and a real-time map of the parking lot is updated. You may view options using an app on your mobile phone or the IoT-enabled car head unit, and proceed to park in a vacant space.

IoT vs. IIoT

IoT has been increasingly impacting practically everything from common everyday activities to businesses of every size and scale. Everything will be affected by the IoT. The application of IoT technologies in manufacturing and other industries is referred to as Industrial Internet of Things (IIoT) or Industry 4.0. It involves the use of smart machines, sensors, big data technologies and machine-to-machine (M2M) communication to gather, analyze and relay data that can detect inefficiencies as well as process or product defects to improve production methods and save businesses time and money.

Although IoT and IIoT are commonly founded on human-object and object-object interaction, they differ greatly in their requirements. IIoT devices are usually deployed in rough environments with varying ranges of temperature and environmental challenges. Additionally, various usage cases spanning diverse workload scenarios mean that IIoT solutions have to be suited to specific applications, as "one size does not fit all" and faster or bigger is not always better.

In the Cloud or At the Edge?

From self-driving cars to oil rigs, airplanes, factory robots, and medical equipment, IIoT use cases generate a steady stream of data. Asset tracking and monitoring, manufacturing automation, predictive maintenance, road safety, smart homes/buildings, and health care are just among the myriad of applications that capture, store, process and transmit data.

Data collected, analyzed and retrieved are usually of critical importance and can even be worth more than the devices that store them. Data corruption or loss, as well as wrong analysis and inaccessibility can disrupt operations and cause disastrous results. As such, it is crucial that IIoT storage solutions be absolutely reliable, durable and secure.

A few years ago, it was commonly thought that everything was going to the cloud. Today, however, the IIoT revolution is happening, not in the cloud but at the edge.

Cloud storage, in simplest terms, refers to storing and accessing data over the Internet instead of the storage device on your computer. The cloud offers many advantages, such as the ability to retrieve files from any device in any location with available Internet connection. Multiple users can also access the same files at the same time as long as they have the necessary passkey.

IIoT applications that generate hundreds of terabytes and petabytes of data by the hour, however, may be unable to transmit such huge amounts of data over the Internet in real time. It is not only costly, but could cause network congestion and slow the connection due to bandwidth concerns. Some critical applications require real-time processing and retrieval, and relying on the network or the Internet could cause delays that will render the data irrelevant or even result in undue risks to life or property.

Due to the need for faster, real-time processing especially for many IIoT applications, edge computing has become a more viable alternative. Simply put, edge computing is storing, analyzing and processing critical data at or closer to the data source rather than in a centralized or cloud-based location. Edge computing offloads the network, cuts transmission costs, and optimizes the data collected for immediate insight or swift response.

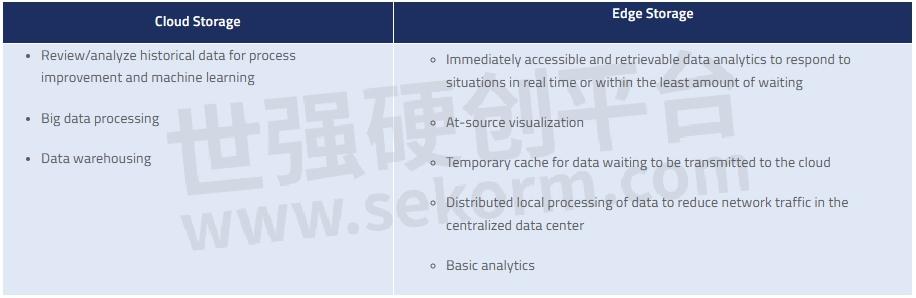

Considering their pros and cons, the table below shows respective ideal use cases for cloud and edge storage:

Table 1. Ideal use cases for cloud and edge storage

Flash Storage Challenges for IoT/IIoT

Flash storage devices are used in cloud and edge computing and industries typically use a combination of both storage solutions. Depending on the types of data being collected, analyzed and processed and the immediacy of analytics needed, systems will have to be designed to respond smartly, whether it is delivering data at the fastest speed or analyzing vast amounts of historical data.

Frequent Writes: Impact on Endurance

IoT/IIoT-generated data is broadly categorized into two types. Large files like videos and images such as those from surveillance cameras are usually accessed sequentially; meaning, the files are read one after another, from the beginning in the order they were stored. Small files, which are typically in bytes and just less than 1 page in size such as log files captured from sensors or recorders can be very numerous and are typically read/written randomly, or in no particular order.

Considering the nature of flash memory, which requires data to be programmed or written to at the page level and deleted at the block level, frequent and random writing of small data files will result in high write amplification. Since flash memory can be written to for a finite number of times, frequent writes can decrease endurance faster.

ATP Solutions

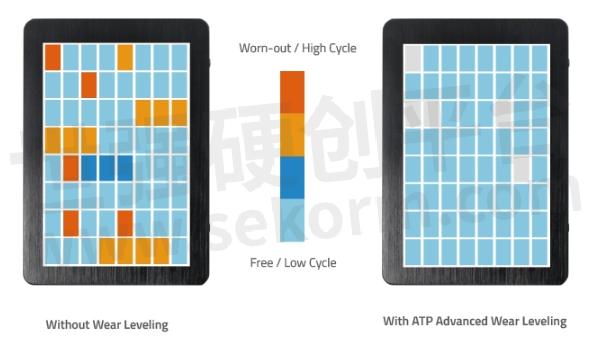

To prevent the fast decline of flash memory endurance resulting from frequent, small-file write applications, ATP Electronics flash products use Advanced Wear Leveling, which evens out the erase count of all blocks to effectively "wear level" the entire flash storage device to extend the life expectancy. The ATP SD Life Monitor / S.M.A.R.T. provides tools for providing early warning to prevent data wear out and spare block exhaustion. Using a friendly interface for monitoring various indicators of drive reliability and other attributes, users can plan way ahead and replace the flash storage device before it wears out, saving data and precious financial resources.

Figure 2. ATP Advanced Wear Leveling manages the reads and writes across blocks to optimize the overall life expectancy of a flash product.

Frequent and Seldom Reads: Read Disturb and Data Retention Issues

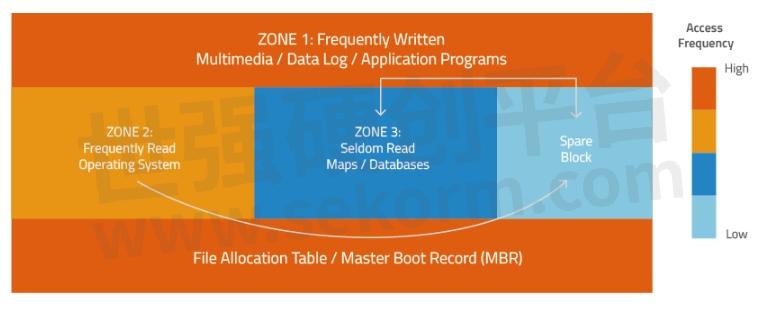

Storage for IoT/IIoT is usually pre-loaded with data requiring high reliability under frequent or continuous reading (e.g., operation system) and long-term data retention (e.g., application programs).

A memory block containing data that are frequently read but not overwritten, moved or deleted can cause threshold voltages of unread cells in the same block to shift to different logical states. This phenomenon, called "read disturb error," affects surrounding memory cells that are seldom accessed, and will cause possible data loss if the errors exceed the error correcting code (ECC) threshold.

Constant operation under wide temperature ranges can affect the ability of a memory cell to hold charge, resulting in data retention concerns that could affect the integrity of stored data and the operation of applications.

ATP Solutions

To address read disturbance and data retention concerns, ATP flash storage products feature advanced NAND flash controller mechanisms like AutoRefresh and Dynamic Data Refresh. The flash controller counts the number of reads to a block since the last erase. If the memory cells have been read for a certain number of times and the read count has reached the predefined threshold value (the maximum number of errors that can be corrected by the ECC), ATP AutoRefresh automatically backs up data to new blocks to prevent data loss and corruption. For seldom-accessed areas, ATP Dynamic Data Refresh runs automatically in the background, sequentially scanning the user area flag record without affecting the read/write operation to reduce the risk of read disturbance and sustain data integrity.

Figure 3. ATP AutoRefresh moves data to a healthy block before the error bits in a block reach or exceed the preset threshold value. This prevents the controller from reading blocks with too many error bits to avert read disturb and data corruption.

Extreme Temperatures and Harsh Operating Environments: Reliability and Durability Concerns

IoT hardware in industrial applications typically operates in harsh conditions including, but not limited to extreme temperatures, humidity, pressure, vibration, shock, ambient radiation, dust, sand, power supply instability, and long-term reliability across all such conditions is highly critical.

ATP Solutions

To ensure extended reliability in harsh operating conditions, ATP conducts comprehensive, in-depth testing from the NAND IC level through the mass production level. Rigorous power cycling tests ensure data integrity under real-world power supply conditions. Industrial temperature-rated NAND flash products undergo testing within wide temperature operating ranges from -40°C to 85°C to make sure they can withstand and perform reliably under extreme temperatures. Select flash products feature temperature sensors and dynamic thermal throttling mechanism to maintain cool operation without drastic drops in performance.

Conclusion

For data in the cloud or at the edge, ATP offers industrial-grade flash storage solutions that meet stringent endurance, retention and reliability requirements of IoT/IIoT. As a member of the Intel® Internet of Things Solutions Alliance, ATP is a qualified IoT/IIoT hardware manufacturer offering memory and storage solutions designed to meet the growing needs and challenges of a connected world. For more information on IoT/IIoT-ready ATP products, visit the ATP website or contact an ATP Distributor/Representative in your area.

- +1 Like

- Add to Favorites

Recommend

- News | NAND Flash Storage Solutions for the Data-Driven 5G Era | ATP

- SMART DuraFlash BGAE540 EMMC Is a Soldered-down Flash Storage Solution Provides Stable High-density Embedded Storage

- ATP Electronics Exhibits Latest Memory and Storage Solutions at Japan IT Week’s ESEC Spring

- Alliance Memory to Highlight Latest SRAM, DRAM, Flash, and Storage Memory ICs at Embedded World 2022

- SMART’s DuraFlash N200 SATA M.2 2242 SSDs Provide an Economic Yet Highly Reliable Mass Storage in a M.2 Form Factor

- Speed and Storage: The Role of Flash Memory in the Automotive Industry

- SMART Modular Introduces PCIe NVMe Flash Storage Products in M.2 Type 1620 BGA Package and M.2 2230 Module

- SMART’s DuraFlash N200 SATA 2.5” Solid State Drives Provide Economic Yet Highly Reliable Mass Storage

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.