How RX 32-bit MCU Touch Technology Has Contributed to Rinnai Good Design Award-Winning Domino-type Gas Built-in Stove | Renesas

To celebrate RX 10th Anniversary, we deliver the voice of our RX microcontroller customers.

Rinnai Corporation (hereinafter referred to as "Rinnai") made remarkable achievement by winning both internationally well recognized design awards, namely the "Good Design Award" in Japan and "Red Dot Design Award" in Germany for their Domino Style gas stove. In this very important year for Rinnai, we decided to interview them to find out how RX130 has contributed to their award winning product.

The meeting was held in Rinnai office and set up by Ryoden Shoji, a dealer of Renesas. The domino-type gas built-in stove was presented to us during the interview, as though we were in the showroom. We were impressed with the posh user interface (UI) operations.

- What is the Domino-type gas built-in stove (G:101) concept that won the Good Design Award?

Ueno: It is an elegant and posh product suitable for the kitchen of a luxury house with a high quality being made in Japan. It is a new market that we have not venture into before. Normally, a black top surface is printed black on the back of a transparent glass, leaving the display area unprinted. However, this methodology will reveal the operating panel when the power is turned off and that will impair the product appearance quality. Hence, this product uses a black glass and we are particular in not displaying the operating panel once the power is turned off.

Yokoyama: The new luxury product development is part of the branding activities promoting further globalization in our 100th anniversary since the company is founded. I wanted to create a product that looks like a decorative craft without displaying the operating panel once the power is turned off, and when it is turned on it will be a high-quality design with a simple UI emerging softly.

Domino-type gas built in stove in the meeting room: Looks as though it is in a showroom

Left: During power off (Only the graphics of the power switch can be seen), Right: During power on (the blue of the flame shines in black)

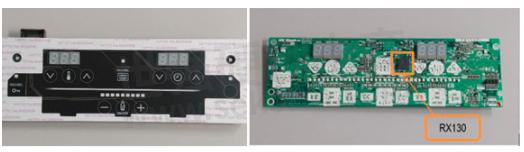

Left: Touch key electrode sheet; Right: control board of operating panel (placed directly below the electrode sheet)

- What is the reason for using the touch key method for the operation panel?

Ueno: This is a drop-in stove with no front panel, so we place the control panel on the top, and we wanted to make the operating panel completely flat to show the beauty when the power is turned off.

Soga: On top of the functional aspects, I think that touch keys are suitable as "simple and good designed" UI. In addition to the visual sense, the other five senses quality such as touch and sound will be required for producing luxury products in the future. Hence, the touch keys are suitable in this respect as well.

Why RX130? The answer is the number of touch key ports of 36 channels, the sensitivity to detect correctly even if a 4mm thick glass is inserted, and the noise-proof function.

- What is the reason of selecting RX130 for the touch key control unit microcontroller?

Yahata: 36 touch key ports were attractive. All your competitors only offer 10 to 20 channels. I wanted to have the number of ports because I wanted to divert the touch keys to other stove products in the future. In addition, the IO ports can be used for either touch keys or other general purposes or LED drive, which is very flexible to implement the whole system with 1 chip that helps to reduce the PCB size as well as total BOM cost generating higher saving.

The glass was thickened to avoid the heat effect from the stove to the electrode sheet, so a self-capacitive, highly sensitive touch key function was necessary. It is also important that RX130 consumes less current during operation and standby because the standby current needs to be considerably small for a battery-powered stove.

Soga: Renesas microcontrollers have the advantage of a high accuracy built-in oscillator. When considering the selection of microcontrollers, the level of accuracy required in the product is increased based on Renesas microcontrollers.

- What are the technical issues and difficulties involved in actual development?

Ueno: There were many problems such as restricting the printed circuit board space, adjusting the temperature of the operating part, and adjusting the display of the operating panel pictogram. For the display adjustment, we used a correction filter to ensure a white LED shining through the black glass continues to look white, which normally becomes orange, and we made a prototype by gradually changing the arrangement of the LEDs to adjust the brightness. The number of prototypes created was more than the normal development, just for the appearance alone.

Soga: The IH section has been devised to take into account the heat effect on the electrode sheet because the user may place the hot pot on the operation panel. We use the touch key and spring type switch for different purpose, placing importance on safety. For example, using a spring type power switch that can turn off when there is any trouble.

Yahata: I have two points. The first point is IEC61004-6 immunity test, where the touch key did not respond when noise was applied, and we were struggling to take measures in resolving the problem. The inability of the user to extinguish the fire is extremely dangerous and is unacceptable. This issue was finally solved by using a function that can change the driver frequency for each touch key of RX130. The second point is the implementation of failure detection of the operating panel. We have repeatedly altered and evaluated the pattern on the electrode sheet. Also, we worked hard with Ryoden and Renesas by exchanging ideas such as within a day when a new pattern emerged. However, even if the electrode patterns were changed, the software could only be changed by adjusting the sensitivity. The sensitivity adjustment tool (QE for Capacitive Touch) was used to easily change the software. In addition, the tool generated the program code, so trial and error could be done in the hardware development division. Since it is not necessary to change the constants around the touch ports, the QE for Capacitive Touch tool is helpful to clear strict requirements specifications within a tight schedule.

Yokoyama: In my experience, Renesas's microcontroller is somehow more noise resistant than others.

Rinnai office: Remote participants shown on the front screen and domino-type stove is placed on the right

- Please tell us your personal thoughts on what kind of development you would like to pursue in the future.

Ueno: AI and Digitalization to the IoT world. We want to provide new services tailored to each person by connecting things.

Soga: I would like to challenge on designing products that appeal to the five senses. I would like to realize a product that changes lifestyles and culture, such as a gas garment dryer that realizes "lifestyles that do not require hanging out the laundry."

Yahata: I think that we would like to go beyond the boundaries of manufacturers and try to link both gas appliances and home appliances that cannot be linked thus far due to different communication methods. For example, I think household chores could become easier if we could connect gas laundry dryer and washing machines.

Yokoyama: For Rinnai’s next 100 years, I would like to create products that aim for health, soundness, and excitement. Various advanced developments are required not only in the UI, but also in sensing, communication, and power electronics. In particular, I would like to think about linking information to services while sensing it.

- +1 Like

- Add to Favorites

Recommend

- Renesas 32-bit RX at the Closing of 10th Anniversary: RX roadmap continues to expand

- Renesas‘ RX Security Solutions Provide A Unique Hardware Technology, Implementing Robust IoT Security Easily

- Renesas RX Becomes World‘s First General-Purpose MCU to Obtain CMVP Level 3 Certification Under NIST FIPS 140-2

- Renesas DSP Solution on Renesas Lab on the Cloud, Input Analog Signals Directly From A Signal Generator To The Rx231 Microcontroller Evaluation Board

- The Past and the Future of Renesas RX Family Software

- Renesas Ships 1 Billionth Device From RX Family of 32-bit Microcontrollers

- Evolve Your HMI Effortlessly with Renesas RX Microcontrollers and Serial LCD

- Renesas RA and RX families of MCUs Offer a Comprehensive Ecosystem Enabling Users to Effortlessly Connect to Their Preferred Cloud Services

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.