Laird Offers Solutions for Datacenter Optical Transceivers and Modules

BACKGROUND

Global IP traffic is swamping datacenters. Yet it is Internet traffic originating or terminating within the center itself which dominates overall data handling. This makes efficient switch design imperative. Ideally, the number of ports in a rack unit should match the capacity of the switch’s application-specific integrated circuits (ASICs). Optical transceivers and modules thus become design challenges. One example is the compact, smallform factor, double density, and hot-pluggable QSFP optical transceiver from the design team of a major manufacturer. The transceiver can support 36 ports of 400GbE in a single rack unit along with 14Tb/s of bandwidth. A second is the manufacturer’s SFP optical module. The added power, density and size limits coupled with higher bandwidth present hurdles to designers. They need to satisfy performance demands in the face of multiple sources of stray EMI and rising heat loads affecting both optical modules.

CASEBOOK SITUATION

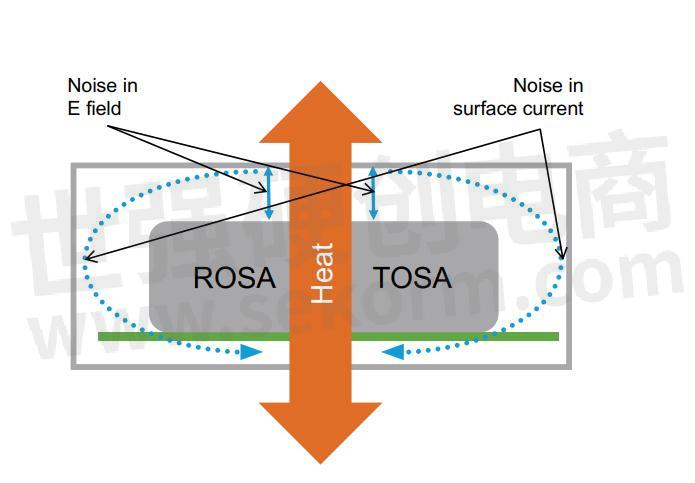

The two original designs were inadequate with one containing a shielding solution of only 5dB to 6dB suppression of EMI noise. EMI sources were many. They included the driver IC, the connector between the transmitter optical sub-assembly and the receiver optical sub-assembly (TOSA/ROSA) and the internal PCB, and the connector between the internal PCB and the adapter. EMI noise surface current was most noticeable along the side walls of one module’s shell. Of significant concern was supplying grounding/shielding to TOSA/ROSA to block noise emerging from the optical module’s front opening. Unwanted heat was emanating from TOSA/ROSA, the laser diode driver and the DSP IC. (Heat direction is to the top and bottom, requiring PCB bottom-side heat transfer as well.) Future QSFP and SFP designs would require an overall reduction in power consumption to limit temperatures.

RESOLUTION

After reviewing alternatives, the design team elected to align its expertise alongside the skills of materials science and engineering experts at Laird Performance Materials. The company produces advancements in the material sciences involving multi-functional solutions. A single Laird process design simultaneously resolves EMI and heat issues affecting component performance.

IMPLEMENTATION

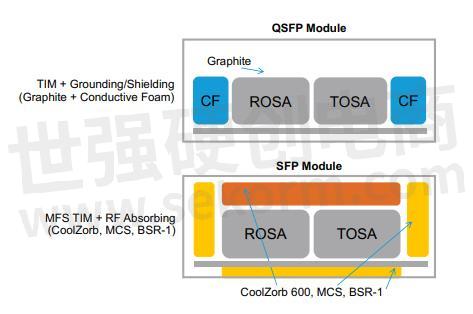

Laird advised 10dB suppression of noise for a single line card, 8dB for two cards, and 6dB for four cards (half rack). Each line card has 12 optical modules. Laird also analyzed which type of RF/microwave absorber to utilize. Analysis was conducted at 26GHz in HFSS. For the SFP module, five different absorber placement positions were tested along with material thicknesses of 0.010in.,0.020in. and 0.040in. Testing confirmed that Laird™Eccosorb® BSR-1 at a thickness of 0.10in, Laird Eccosorb®MCS at a thickness of 0.020 and Coolzorb 600 at a thickness of 0.060”. would provide the ideal solution. To shield TOSA/ROSA specifically on the QSFP module, designers had been using a stainless-steel gasket with fingers, but gaps in the corners revealed an inadequate level of EMI suppression. Laird has recommended replacing this gasket with a metal folded shield. Additional help with thermal loads could come from a graphite barrier and from Laird Conductive Foam CF515 surrounding TOSA/ROSA on the sides, with Laird thermal interface materials transferring heat away from the top and bottom of TOSA/ROSA.

RESULTS

Testing is confirming to the manufacturer that by applying a combination of Laird Eccosorb MCS, Eccosorb BSR-1 and Laird Coolzorb 600, it will significantly lower total radiated power (TRP) to levels falling within acceptable ranges. Equally significant, the Laird solution would deliver the best cost benefit. Additional testing also has confirmed that either approach would enable the optical modules to remain within acceptable high temperature ranges, even at the most tightly controlled datacenters.

- +1 Like

- Add to Favorites

Recommend

- Laird Signed an Authorized Distributor Agreement with Sekorm

- Laird Releases Tflex™ Sf10 Series, a Silicone-free Gap Filler Delivering 10 W/mk Thermal Conductivity

- Laird Performance Materials‘ new electrically conductive elastomers EcE 130 and EcE 135

- The Laird™ Ttape™ 1000A thermally conductive adhesive tape delivers best-in-class thermal resistance

- Laird Performance Materials‘ Graphite-over-Foam, GOF3000 thermal and EMI gasket,Shield EMI and transfer heat in compact spaces

- Sekorm Offers More Than 150,000 Electronic Components in Stock, Ensuring Supply Chain Assurance

- More than 150 Electromechanical Components Brands Cooperate with Sekorm

- Nanochap Nerve Electrical Stimulation Chip Stim Engines Series NS4 in the Micro-current Gua Sha Instrument on the Use of Multi-functional Multi-speed

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.