Crocus TMR Sensors with Higher Sensitivity, Better Linearity and Less Temperature Sensitivity Are Becoming More Popular in EV BDUs

As EV adoption continues to outpace even the most optimistic projections, the focus has been on the range, efficiency – and increasingly, the safety – of batteries. Today’s requirement is 24/7 monitoring of the vehicle’s current, voltage, and temperature – all in a 100% safe design.

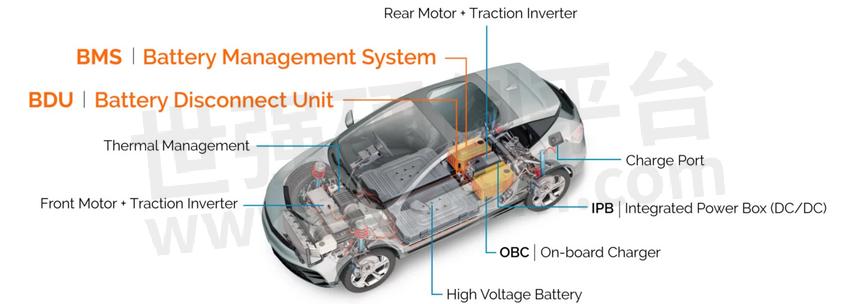

At the core of the safety technology is the Battery Management System which uses a Battery Disconnect Unit (BDU) to connect the battery to the vehicle’s high-voltage powertrain and charging systems.

The BDU identifies overcurrent and short circuits and automatically disconnects the battery, preventing the flow of electricity to damaged components, and reducing the risk of electric shock or fire.

When performing maintenance or repairs on an EV, technicians need to ensure that the high-voltage battery is mechanically disconnected to prevent any risk of electric shock or accidents. The BDU facilitates this disconnection. In addition, in some cases, the BDU acts as an anti-theft feature, making it challenging for potential thieves to start or operate the vehicle.

EV High Voltage Components

The Importance of Current Sensing in BDUs

As electric vehicle technology evolves and safety standards continue to improve, some advanced electric vehicles are incorporating additional safety features, including pyro fuses or other similar devices.

According to Eaton, a BDU Manufacturer, “Current EVs rely on one of three traditional BDU configurations – fuse and contactor, pyro fuse and contactor, or fuse, pyro fuse and contactor – all used together in a single BDU.”

At the core of BDU architectures are current sensors. Current sensors provide real-time monitoring of the electrical current flowing between the battery and the electrical system. By continuously monitoring the current, the BDU can detect abnormal or excessive current. In the event of a short circuit or other electrical malfunction, the current sensor triggers the BDU to disconnect the battery immediately, preventing potential hazards such as fires or electrical shock.

By measuring the current during charging and discharging cycles, the BDU can ensure that the battery operates within safe limits and prevents overcharging or over-discharging. This helps to extend the battery’s lifespan and maintain its performance over time.

In addition, EVs rely on sophisticated energy management systems to maximize their range. Current sensors in the BDU can contribute to this effort by providing data on the battery’s energy consumption and efficiency. The vehicle’s onboard systems use this information to optimize power usage, allowing the vehicle to travel longer distances on a single charge.

Current Sensing Systems

Shunt current sensors have been historically employed in BDUs due to their simplicity, reliability, and cost-effectiveness. They measure current by monitoring the voltage drop across a resistor placed in series with the current path. The voltage drop is directly proportional to the current flowing through the shunt, allowing for accurate current measurements.

However, EV technology is quickly evolving, and manufacturers are exploring new sensor technologies, most notably, Tunnel Magneto-Resistance (TMR) to further enhance safety, efficiency, and overall performance.

There are multiple benefits to TMR sensors in BDUs

Fast Response

TMR sensors quickly detect changes in the magnetic field generated by the current passing through a conductor. This allows the BDU to rapidly respond to sudden increases in current levels, such as those caused by a short circuit or a component failure. The fast response time enables the BDU to initiate battery disconnection promptly.

Enhanced Safety

TMR sensors can be used in combination with a shunt current sensor to achieve high sensitivity and accuracy. The fast response time of TMR sensors, when complemented by the high accuracy of shunt sensors, optimizes for safety. This proactive approach allows the BDU to meet the requirements for achieving high ASIL ratings.

Non-Intrusive

Unlike shunt, TMR sensors do not require a physical connection in the current path. Instead, they measure the magnetic field generated by the current passing through a conductor. This non-contact sensing method simplifies integration into the BDU and reduces potential issues associated with electrical connections and resistive losses.

Reduced Power Consumption

TMR sensors have lower power consumption compared to shunts, important for energy efficiency in vehicle range and battery life.

High Accuracy and Linearity

TMR’s high level of precision is essential for BDUs to accurately detect abnormal currents and trigger disconnection.

Insensitivity to Thermal Effects

Shunt current sensors can be affected by self-heating or ambient temperature variations. TMR’s reduced thermal influence ensures more consistent and reliable current measurements.

Design Flexibility

TMR sensors are available in multiple form factors and configurations, allowing for design flexibility in the BDU. They can be tailored to specific space constraints and environmental considerations, making them suitable for a wide range of EV applications.

Crocus TMR Sensors

For all of these reasons, TMR sensors are superior performers in EV BDUs. Nowhere is this superiority more evident than in the Crocus TMR CT45x contactless sensor family and the new CT405x, with a total output error of less than ±1.0% full-scale (%FS) over the full temperature range. CT45x features a 300ns response time, so it quickly responds to changes in current. Finally, both sensor families have ultra-low noise of 9.0 mARMS and low power consumption of <10mA.

Suncall Corporation, an auto parts manufacturer, is releasing a new lineup of electric vehicle products based on a magnetic sensor built around an integrated sensor from Crocus. This new current sensor achieves a high accuracy of 1.0% or less over the entire temperature range and a low power consumption of 6mA or less, making it more efficient than conventional products.

There’s a reason carmakers are increasingly turning to Crocus TMR sensors for BDUs. This combination of higher sensitivity, better linearity, less temperature sensitivity, and lower power consumption is unbeatable, especially when you consider they are isolated, small, lightweight, and less expensive than legacy current sensors.

- +1 Like

- Add to Favorites

Recommend

- Crocus CT45x Family’s XtremeSense TMR Sensors Deliver High Precision and High Current Measurements for EV Motor Control

- Crocus Technology’s new line of contactless current sensors with a signal-to-noise ratio as high as 77 dB

- Crocus Technology TMR Sensors such as CT430/1 Have the Most Reliable and Efficient Performance in Overcurrent Protection

- The CT45x showcases the advantages of TMR sensors to rethink and simplify solutions in the high precision, high current application space

- Nxp Licenses Advanced TMR Sensor Technology From Crocus Technology

- US Patent and Trademark Office rules in favor of Crocus Technology in patent invalidation case

- Crocus Technology Acquired by Allegro MicroSystems to Accelerate Innovation in TMR Sensing Technology

- Crocus Technology and TowerJazz Qualified CTSX Magnetic Sensors and Volume Manufacturing Launched

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.