Crocus Technology TMR Sensors such as CT430/1 Have the Most Reliable and Efficient Performance in Overcurrent Protection

It’s been a problem since day one. Simple physics dictates that when current increases through a wire, it gets hot. When current flows through an unintended, low impedance path, it becomes excessive, and you get a short. Welcome to overcurrent.

Today, current monitoring is becoming increasingly critical in the measurement of everything from smart home security to electric vehicles. Simply put, higher performance in smaller form factors is required in a myriad of consumer products and edge devices. That means overcurrent protection (OCP) is also becoming critical.

To achieve OCP, the simplest and most common implementation is adding a fuse in the design. But traditional fuse systems are essentially reactionary, alerting to a current issue after it’s already happened. The horse is already out of the barn. And now the fuse needs to be manually replaced, a non-starter for today’s sophisticated monitoring systems. Maybe most importantly, a fuse system offers no visibility into the actual operating conditions of the system.

Similarly, traditional temperature monitoring is also measuring a symptom rather than the root problem. The system has a current problem, the system gets hot. And, like a fuse system, it gives no information on operating conditions.

Optimal overcurrent protection provides this intel, alerting you before there’s an issue.

Today, reacting to a blown fuse is no longer acceptable. Today’s systems require OCP’s ability to monitor and detect any potentially harmful event. At the same time, this monitoring ensures better bandwidth and efficiency.

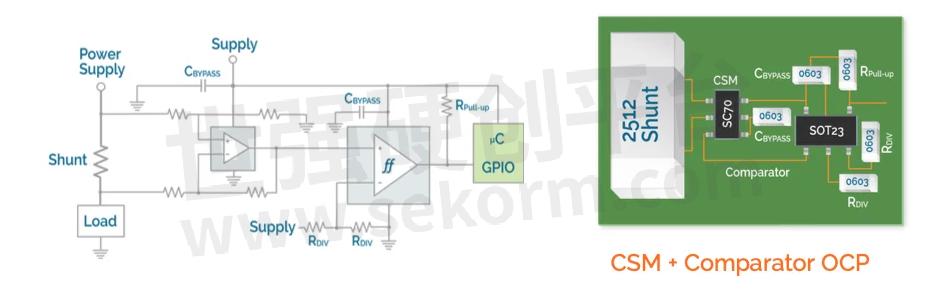

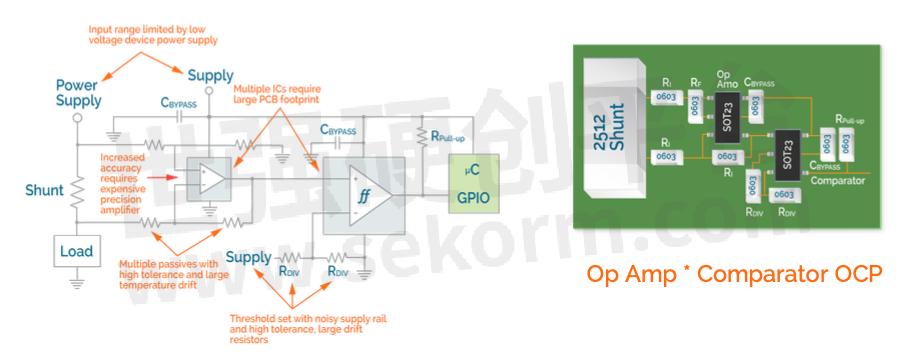

Overcurrent Protectors

One step up from a fuse, the combination of shunt resistor + Operational Amplifiers is one of the cheapest options, providing a fast response time when high-speed amps and comparators are used. They essentially amplify the voltage drop across a shunt resistor to create an output signal that is sent to a comparator. But you get what you pay for: these resistors typically have high resistance value distribution, suffering from high-temperature drift referred to as TCR. Leading to an inaccurate OCD system. You can replace the op-amp with a current sense amplifier, also called a current shunt monitor, to provide a more accurate measurement and offer fast response time – as long as you have a fast comparator. They employ external gain setting resistors for more accurate measurement. In addition, they are smaller and have better temperature characteristics due to compensation and low TCR shunt resistors, but these solutions are costly and do not provide galvanic isolation.

Classic Op-amp & Comparator

Classic Op-amp & Comparator

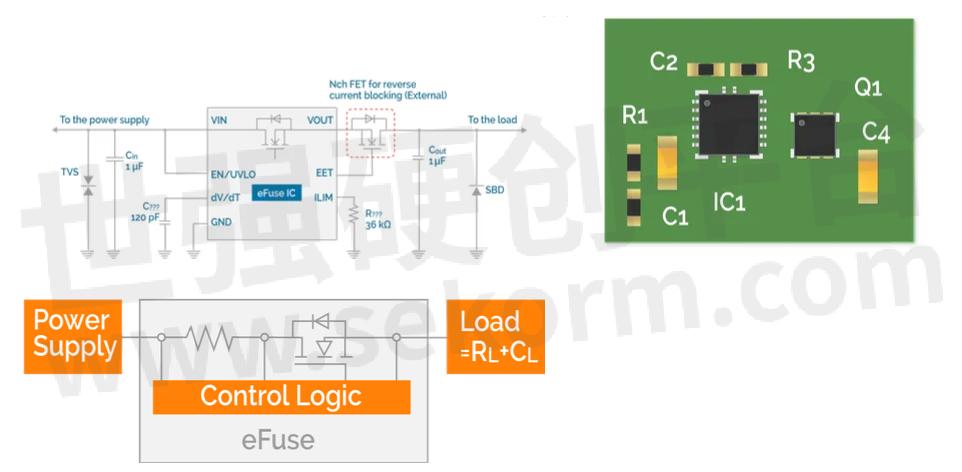

Electronic fuses (eFuse) are a version of this: shunt + operational amplifier + power MOSFET. The eFuse also offers better speed, low-current operation, and reset ability. At the same time, drawbacks include complex construction, the requirement of a bias current to operate, and the lack of high-voltage protection.

Figure 1: In an eFuse, as current from supply to load passes through a sense resistor, it is monitored via the voltage across that resistor; when it exceeds a set value, the control logic turns the FET off, blocking the flow of current to the load.

Hall effect sensors optimized for OCP require a certain level of compromise. Typically, to maximize bandwidth and response time, these sensors cannot apply the compensation mechanisms for offset and temperature drift. This yields sensors that have limited performance under temperature and cannot be used as current sensors.

For higher currents, Hall sensors typically use a flux ring or collector surrounding the contactor’s bus bar or output feeder. These sensors feature higher accuracy, and isolation between primary and secondary circuits but suffer from higher hysteresis which is not ideal in OCP applications.

Yet Hall suffers from historic weaknesses: low bandwidth, output drift, non- linearity over temperature. The magnetic core exhibits hysteresis, and saturation leads to non-ideal offset and linearity characteristics. Additionally, the core contributes to a comparatively large size and weight.

The Tunnel Magneto-Resistance Advantage

For the most reliable and efficient over current protection, Tunnel Magneto-Resistance sensors (TMR sensors) deliver faster response time, better temperature stability, and lower power consumption than eFuse or the other OCP solutions.

The sensors are solid-state devices that provide the highest level of accuracy and require little power – less than 1/3 of Hall effect sensors and 100X better than eFuse. They are eminently suitable for permanent and transient overcurrent conditions as seen in hot swapping of PCBs or AC supply lines.

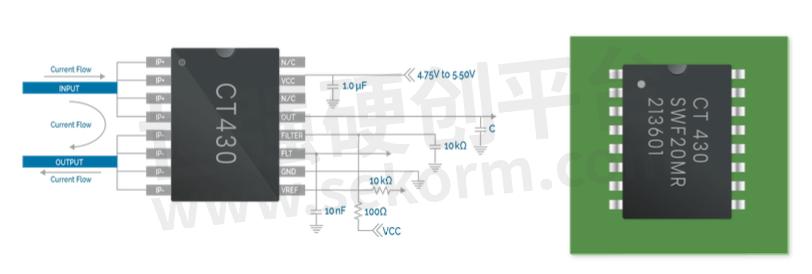

Crocus Technology CT430/1 delivers Overcurrent Fault Detection (OCD) with an integrated OCD circuitry to identify out-of-range currents, which is output on the fault pin (FLT#). The FLT# is an open drain, active LOW digital signal.

This high bandwidth and ultra-low noise integrated sensor enable high accuracy current measurements for OCP. A current overload translates to a strong magnetic field being applied to the sensor. If this magnetic field is higher than the sensor's operating range of ±65 A, it will drive the sensor outside of its linear range. This, however, will not damage the sensor. The sensor resumes normal operations as soon as the external magnetic field is back within the operating range.

The current sensor supports 8 different current ranges where the integrated current carrying conductor (CCC) will handle from 20 A up to 65 A of current and generates a current measurement as a linear analog output voltage. This voltage is used to accurately monitor the current as well as detect an overcurrent condition. Due to the ultra-low resistance of the conductor, 0.5mOhm, it also doesn’t generate excessive heat. The CT430/1 achieves a total output error of less than ±1.0% full-scale (FS) over-voltage and the full temperature range.

CT430 and CT431 isolated current sensors feature fast response with a 1MHz bandwidth and 300ns response time; high signal-to-noise (SNR) with ultra-low noise of 9.0mARMS. These Crocus Technology devices include integrated common-mode field rejection of 54 dB to ensure stray fields do not impact measurements in the working application. The CT430/1 by Crocus Technology is offered in an industry-standard 16-lead SOIC-Wide package.

If a higher current is required Crocus offers the CT45x contactless current sensor for applications of 100A up to ~4000A and higher. In this application, the PCB trace or a bus bar is used to carry the current and the sensor measures the field strength generated by the flow of current. This results in a lossless overcurrent implementation. This also eliminates the need of paralleling an eFuse or other discrete circuitry to achieve overcurrent protection and simplifies the solution.

The bottom line: Today’s cutting-edge systems require cutting-edge overcurrent protection. The response to an event needs to be fast and accurate to protect the overall system. Crocus’ XtremeSense® TMR technology delivers next-generation performance while reducing potential thermal or electrical impacts on the system. It also simplifies the system with a reduced number of components and a smaller size.

- +1 Like

- Add to Favorites

Recommend

- Crocus Technology‘s CT430 TMR isolated current sensor Reference Design with Digital Output Simplifies Implementation

- Crocus TMR Current Sensors CT430 and CT431 Simplify the Product Design While Still Achieving Higher Efficiency Solutions

- Nxp Licenses Advanced TMR Sensor Technology From Crocus Technology

- US Patent and Trademark Office rules in favor of Crocus Technology in patent invalidation case

- Crocus Technology Acquired by Allegro MicroSystems to Accelerate Innovation in TMR Sensing Technology

- Crocus Technology and TowerJazz Qualified CTSX Magnetic Sensors and Volume Manufacturing Launched

- Crocus Technology’s new line of contactless current sensors with a signal-to-noise ratio as high as 77 dB

- Crocus Technology Launches First True Z-axis TMR Sensor Delivering Unparalleled Performance for Next-Gen Position and Current Sensing Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.