ROHM Develops Ultra-Low-Power On-Device Learning Edge AI Chip,Enabling Real-time Failure Prediction Without Cloud Server Required

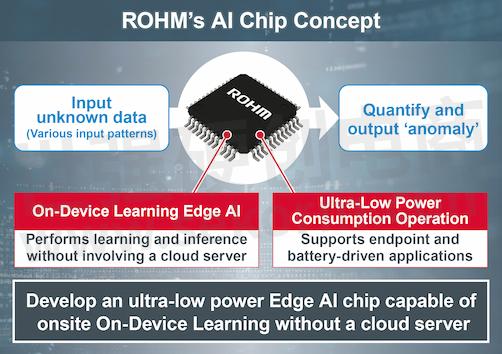

ROHM has developed an on-device learning AI chip (SoC with on-device learning AI accelerator) for edge computer endpoints in the IoT field. It utilizes artificial intelligence to predict failures (predictive failure detection) in electronic devices equipped with motors and sensors in real time with ultra-low power consumption.

Generally, AI chips perform learning and inferences to achieve artificial intelligence functions. As learning requires that a large amount of data gets captured, compiled into a database, and updated as needed. So, the AI chip that performs learning requires substantial computing power that necessarily consumes a large amount of power. Until now it has been difficult to develop AI chips that can learn in the field consuming low power for edge computers and endpoints to build an efficient IoT ecosystem.

Based on an ‘on-device learning algorithm’ developed by Professor Matsutani of Keio University, ROHM’s newly developed AI chip mainly consists of an AI accelerator (AI-dedicated hardware circuit) and ROHM’s high-efficiency 8-bit CPU ‘tinyMicon MatisseCORE™’. Combining the 20,000-gate ultra-compact AI accelerator with a high-performance CPU enables learning and inference with an ultra-low power consumption of just a few tens of mW (1000× smaller than conventional AI chips capable of learning). This allows real-time failure prediction in a wide range of applications, since ‘anomaly detection results (anomaly score)’ can be output numerically for unknown input data at the site where equipment is installed without involving a cloud server.

Going forward, ROHM plans to incorporate the AI accelerator used in this AI chip into various IC products for motors and sensors. Commercialization is scheduled to start in 2023, with mass production planned for 2024.

Professor Hiroki Matsutani, Dept. of Information and Computer Science, Keio University, Japan

“As IoT technologies such as 5G communication and digital twins advance, cloud computing will be required to evolve, but processing all the data on cloud servers is not always the best solution in terms of load, cost, and power consumption. With the ‘on-device learning’ we research and the ‘on-device learning algorithms’ we developed, we aim to achieve more efficient data processing on the edge side to build a better IoT ecosystem. Through this collaboration, ROHM has shown us the path to commercialization in a cost-effective manner by further advancing on-device learning circuit technology. I expect the prototype AI chip to be incorporated into ROHM's IC products in the near future.”

About tinyMicon MatisseCORE™

tinyMicon MatisseCORE™ (Matisse: Micro arithmetic unit for tiny size sequencer) is ROHM’s proprietary 8-bit CPU developed for the purpose of making analog ICs more intelligent for the IoT ecosystem. An instruction set optimized for embedded applications together with the latest compiler technology to deliver fast arithmetic processing in a smaller chip area and program code size. High-reliability applications are also supported, such as those requiring qualification under the ISO 26262 and ASIL-D vehicle functional safety standards, while the proprietary onboard ‘real-time debugging function’ prevents the debugging process from interfering with program operation, allowing debugging to be performed while the application is running.

Detail of ROHM’s AI Chip (SoC with On-Device Learning AI Accelerator)

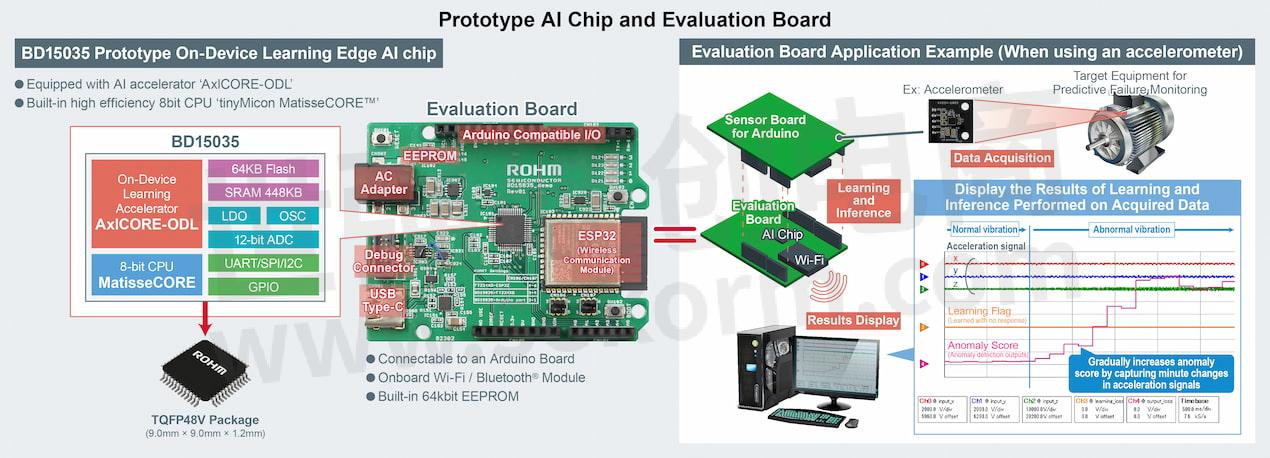

The prototype AI chip (Prototype Part No. BD15035) is based on an on-device learning algorithm (three-layer neural network AI circuit) developed by Professor Matsutani of Keio University. ROHM downsized the AI circuit from 5 million gates to just 20,000 (0.4% the size) to reconfigure for commercialization as a proprietary AI accelerator (AxlCORE-ODL) controlled by ROHM’s high-efficiency 8-bit CPU tinyMicon MatisseCORE™ that enables AI learning and inference with an ultra-low power consumption of just a few tens of mW. This makes the numerical output of ‘anomaly detection results’ possible for unknown input data patterns (i.e. acceleration, current, brightness, voice) at the site where equipment is installed without involving a cloud server or requiring prior AI learning, allowing real-time failure prediction (detection of predictive failure signs) by onsite AI while keeping cloud server and communication costs low.

For evaluating the AI chip, ROHM offers an evaluation board equipped with Arduino-compatible terminals that can be fitted with an expansion sensor board for connecting to an MCU (Arduino). Wireless communication modules (Wi-Fi and Bluetooth®) along with 64kbit EEPROM memory are mounted on the board, and by connecting units such as sensors and attaching them to the target equipment, it will be possible to verify the effects of the AI chip from a display. This evaluation board will be loaned out from ROHM sales.

- +1 Like

- Add to Favorites

Recommend

- Silicon Carbide cooperation between SEMIKRON and ROHM Semiconductor: ROHM’s SiC technology empowers SEMIKRON’s eMPack® for the next generation of electric vehicles

- Notice of Integration of ROHM Three Sales Companies in China

- Continental acknowledges ROHM Semiconductor with the “Supplier of the Year 2022 Award“

- ROHM Online Distributor China | Sekorm

- ROHM‘s Nano Energy™ and LAPIS Technology‘s Charge Control IC Help Maxell Energy Harvesting-compatible Evaluation Kit

- ROHM SiC MOSFETs Solve Design Challenges for Leading Solar Energy Company Midnite Solar

- Ultra-Low IQ PMIC from ROHM Selected to Power NXP iMX8M Nano for High Performance Embedded Artists Industrial Control Board

- ROHM’s Product Longevity Program Enables Worry-free Adoption of ROHM Products

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.