LONGSING IoT Connected Smart Logistics Battery Solution

IoT is transforming logistics and supply chain management. Innovation is happening at the level of sensors attached to goods and assets as well as at the networks level, capturing and transferring data all the way from the production line to the point of final delivery as shown in Figure 1. Therefore, battery life would be a key factor for matching this trend. The pulse power required during the signal communication from the circuit to ender users is generally over 10s 2 amperes under various temperature or even extreme temperatures all around the world.

Traditional lithium ion battery cannot meet the requirement due to lack of high peak current output and large capacity loss under extreme low or high temperatures, which will shorten the life significantly. Commercially available lithium thionyl chloride battery (Li-SOCl2) is one of the longest-life primary batteries in the market. However, when you use the battery alone for high pulse application, you will face a problem of its power limitation. The battery enables to discharge only low power like several 10s milli-amperes. If you draw high power from the battery forcedly, the battery will be damaged, resulting in shortening the life. Therefore, in order to make a complementary choice for the long life power solution, in this project, LONGSING will focus on developing the HPC1550 type of rechargeable lithium ion battery with long cycle performance and superior extreme temperature performance by materials development and design of the battery package. Combining with the commercially available ER34615 type of lithium thionyl chloride battery, the one HPC1550+one ER34615 battery pack as shown in Figure 2 will provide sufficient pulse power out at normal or extreme temperatures with superior long cycle life.

Figure 1. IoT connected smart logistics.

Figure 2. Traditional battery (left) and battery pack in this project (right) for the smart cargo tracker

Passivation characteristics of lithium thionyl chloride battery

When the lithium thionyl chloride battery is stored for a long time, the reaction of Li and SOCl2 will produce a dense passivation film on the surface of the metal lithium. The passivation film can prevent the further reaction of Li and SOCl2.

During the discharge process, the overall electrochemical reaction equation is:

4Li + 2SOCl2 → SO2 + S + 4LiCl

"LiCl" is a material that makes lithium thionyl chloride batteries passivate.

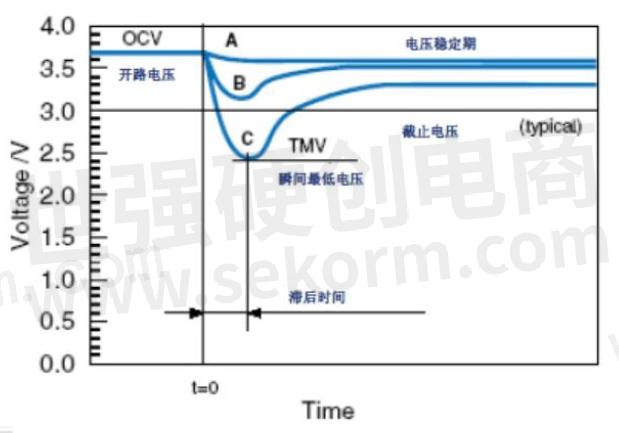

When a lithium chloride (LiCl) film is formed on the surface of the lithium anode, passivation occurs, which impedes the chemical reactions that result in the battery self-discharge.Therefore, when the stored battery is connected to the load for the first time, the passivation layer will cause a high initial resistance, causing the battery voltage to temporarily drop, voltage hysteresis will occur. But as the battery discharges, the passivation film will gradually be eliminated, and the load voltage will gradually rise.

Instantaneous voltage curve (set 3.0V as cut-off voltage)

A small current: no voltage hysteresis,

B Medium current: The working voltage is greater than the termination voltage; the equipment application is not affected,

C Large current: The working voltage drops below the cut-off voltage instantaneously, and a voltage hysteresis phenomenon occurs. The performance is more prominent at low temperatures.

Advantages of passivation:

Because the reaction of Li and SOCl2 can produce a dense passivation film to prevent the reaction from proceeding further, the storage time of lithium thionyl chloride batteries can reach more than 10 years.

Disadvantages of passivation:

After long-term storage of lithium thionyl chloride batteries, battery passivation will reduce the ability of high current pulse output, so that the instantaneous minimum voltage of the battery may be lower than the cut-off voltage of the application.

Battery passivation is inevitable, but its impact can be minimized to meet the requirements of use. In order to eliminate the hysteresis effect of the lithium thionyl chloride battery, obtain the high current pulse capability and enhance the low temperature discharge capability, the battery capacitor combination of ER+HPC from LONG SING are specially designed for many IoT applications.

Pulse cycle test under GSM protocol

GSM uses a combination of both TDMA and FDMA techniques. The FDMA element involves the division by frequency of the (maximum) 25 MHz bandwidth into 124 carrier frequencies spaced 200 kHz apart as already described.

The carriers are then divided in time, using a TDMA scheme as shown in Figure 3. This enables the different users of the single radio frequency channel to be allocated different times slots. They are then able to use the same RF channel without mutual interference. The slot is then the time that is allocated to the particular user, and the GSM burst is the transmission that is made in this time.

Each GSM slot, and hence each GSM burst lasts for 0.577 ms. Eight of these burst periods are grouped into what is known as a TDMA frame. This lasts for approximately 4.615 ms and it forms the basic unit for the definition of logical channels as shown in Figure 3 and Figure 4. One physical channel is one burst period allocated in each TDMA frame.

Figure 5. Transmit Power Waveform of 100 Bytes Data

Test Procedure

In general rule, GSM is the worst case condition for peak current and 2 A peak current is the general boundary at which to size the power rail.

In battery test profile, 2 A constant current discharging last for 1ms is set to emulate GSM transmission peak current and 200 mA constant discharging for 4 ms is set to form a TMDA frame, the 200 mA is a non- transmission power consumption assumption of a GSM application device.

Based on the test results of transmitting 100 Bytes data in laboratory, the overall transmit time is about 5 s as shown in Figure 5, so the frame is repeated 1000 times, the total transmission time is 5 s.

A pulse cycle test designed by following the Global System for Mobile (GSM) communication protocol (2A for 1 millisecond and 150 mA for 4 milliseconds) is conducted with the ER34615+HPC1550 bundle to simulate the battery pack working condition under room temperature. Two different lithium battery brands of ER34615 primary batteries combined with Long Sing HPC1550. The pulse life difference is possibly due to the pulse discharge capability of the primary cells. With the best combination, the battery pack’s life span could be over 10 years of application.

ER+HPC in GSM/GPRS communication

GSM/GPRS communication requirement:

• Standby current 2-5mA. Due to the large current, it is generally used in the long-life design and standby from time to time.

• The peak current of the GSM module can reach 2A, when the signal is good, the peak current could be 1A, the communication time is 45-60S, and the minimum voltage is 3.3/3.1V. Generally, DC-DC boost circuit will be designed. With boost circuit, the battery pack can still work at a minimum of 2.7V, the peak current is 500mA.

• The average current for GSM is 120-150mA, when the signal is bad, it could be 200mA, each GSM cold-start consumed capacity is about 1.5mAh.

• In the application of GPS+GSM, that is, location+communication, the average working current of GPS is 40mA and the duration is about 90S. The entire GPS+GSM process consumes about 2.5mAh with a peak current of 500mA.

• With the help of circuit design, ER34615+HPC1550, the communication frequency does not exceed 4 times/day, and it can work stably at -40~+85℃, especially at -40℃.

ER+HPC in NB-IOT communication

NB-IOT communication requirement:

Theentire communication time is 45-60S,

Averagecurrent 80mA,

Consumptioncapacity 1mAh,

Peakcurrent 350-380mA,

The voltageis not less than 3.1V.

Devicestatic power consumption<10μA

According to the frequency of communication, if the communication is less than 4 times a day, the HPC1520 capacitor can be restored to a voltage of about 3.65V before communication each time. The performance of each pulse is consistent and unaffected, as shown in the curve on the right. The discharge capacity per time is 3.8AS=1.05mAh.

In the application field of NB water meter, the minimum temperature requirement is -10℃. Therefore, the industry basically chooses: ER26500+HPC1520 to ensure a life span of 6+1 years.

LONG SING IOT batteries (Internet of Things batteries, hereinafter referred to as “IOT”) is a power supply system to parallel-connect ER and HPC of high capacity and low self discharge rate, which is also known as pulse-enhanced battery. In addition to an ideal power source that can chronically stand by with low power consumption and instantly pulse-discharge at large current, it serves as a power supply of chronically independent work in the severe environment as required in design. It is a perfect solution of power supply for GPS/Beidou navigation and positioning plus the power utilization mode in the method of GSM/CDMA/GPRS data transmission.

- +1 Like

- Add to Favorites

Recommend

- 4V Hybrid Pulse Capacitor Rechargeable Lithium Cell HPC1550-1S4P Solar Power Solution for Bridge Monitoring System

- Solar Energy+HPC1520+ER14250——Perfect Dual Power Supply Solutions for the OBU of ETC System

- LONGSING IOT Battery in Smart Water Meter Industry

- NB-IOT Intelligent Manhole Cover System Provided a More Convenient And Safe Life for the Public

- Global Iot Battery Leader——LONGSING

- AGV Batteries: Powering the Future of Automated Guided Vehicles

- Maxell Develops CLB640 Coin Type High Capacity Lithium-Ion Rechargeable Battery with a Diameter of Approx. 6mm and Approx. 1000 Charge/Discharge Cycle Characteristics

- Prismatic vs Pouch vs Cylindrical Lithium Ion Battery Cell

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.