LONGSING IOT Battery in Smart Water Meter Industry

The lithium thionyl chloride Battery is connected in parallel with the HPC, and the lithium thionyl chloride battery charges the HPC with a small current through the voltage difference with the HPC. When powering externally, HPC bears most of the current output. Before the next pulse arrives, the lithium thionyl chloride battery rushes HPC to a suitable voltage, and the cycle works like this.

Due to the voltage characteristics of the lithium thionyl chloride battery at no load, even after 80% of the capacity of the lithium thionyl chloride battery is consumed, its no-load voltage can still be maintained at 3.65V (consistent with the new battery), that is, HPC will be charged to 3.65V, consistent with the new battery pack. The discharge capacity of HPC remains basically unchanged, and the cycle reciprocates until the capacity of the lithium thionyl chloride cell is exhausted, ensuring that the service life and discharge capacity of the battery pack are consistent with the estimate. Greatly improve the effective capacity of the battery. ——It can effectively solve the problem of lithium thionyl chloride battery voltage delay and large current pulse discharge problems.

Basic requirements for water meter power supply

With the expansion of smart meters and the addition of more functions, especially the addition of wireless transmission functions, the requirements for batteries are also higher. Combining the situation of two typical smart water meters to illustrate how to select and design the battery.

Electricity characteristics of wireless remote water meters:

Battery life: 8 years

Working temperature: -10℃~+60℃

Minimum voltage of equipment: 3.0V

Electricity characteristics of GSM remote water meter:

Battery life: 2 years

Working temperature: -30℃~+60℃

Equipment working voltage: 5.5~7.5V

1. Voltage delay

After the battery has undergone long-term small current, or after long-term storage or high-temperature storage, the battery's working voltage is lower than the specified voltage during the initial stage of battery discharge. This state is called voltage delay. With the extension of the discharge time, the voltage gradually rises and reaches the specified voltage. This period of time is called "voltage delay time". The voltage delay time is related to the discharge current and temperature. The higher the current, the lower the temperature, the more serious the voltage delay. The influence of voltage delay: After the battery is powered on by a microampere current, it cannot solve the passivation of the battery surface. At this time, when working with high current, if the passivation film on the electrode surface is very thick, the battery voltage may drop below 1.8V in an instant, causing the single-chip microcomputer crash or misjudgment, indicating that the battery is under-voltage or the single-chip microcomputer is out of control, causing the battery to run out of energy.

2. High current pulse capability:

Especially the high current capability under low temperature conditions. At low temperatures, the high current capability of the lithium thionyl chloride battery drops sharply. Coupled with the influence of passivation, the battery voltage will be lower than the device's alarm voltage, causing undervoltage. With the use of the battery, especially when the capacity consumption exceeds 60%, the large current discharge capability of the battery becomes weaker and weaker. The effective capacity of the battery cannot be evaluated. (ER34615 maximum instantaneous discharge current 300mA and maximum continuous discharge current 150mA)

Solution

In view of the characteristics of the water meter and the characteristics of the lithium battery, LONGSING's plan is: Bobbin type lithium thionyl chloride battery + hybrid pulse battery (HPC) form a parallel battery pack—IOT battery.

HPC characteristic parameters:

Working temperature:-40 ℃ ~+85 ℃ High current pulse capability:

The maximum current can reach 15A

Low self-discharge rate:<1%/year

Long life cycle: 5000 100% DOD cycles

Long service life: more than 10 years (exceeding the service life of electrical equipment)

Can be charged and discharged at extreme temperatures

Fully sealed technology using laser welding to ensure no leakage under extreme conditions

Environmental protection green new energy

The working principle of the battery pack is: The lithium thionyl chloride battery is connected in parallel with the HPC, and the lithium thionyl chloride battery charges the HPC with a small current through the voltage difference with the HPC. When powering externally, HPC bears most of the current output. Before the next pulse arrives, the lithium thionyl chloride battery rushes HPC to a suitable voltage, and the cycle works like this. Due to the voltage characteristics of the lithium thionyl chloride battery at no load, even after 80% of the capacity of the lithium thionyl chloride battery is consumed, its no-load voltage can still be maintained at 3.65V (consistent with the new battery), that is, HPC will be charged to 3.65V, consistent with the new battery pack. The discharge capacity of HPC remains basically unchanged, and the cycle reciprocates until the capacity of the lithium thionyl chloride cell is exhausted, ensuring that the service life and discharge capacity of the battery pack are consistent with the estimate. Greatly improve the effective capacity of the battery. ——It can effectively solve the problem of lithium thionyl chloride battery voltage delay and large current pulse discharge problems.

Experimental proof

According to the characteristics of the wireless remote water meter battery, the following design is made: It is calculated that the required capacity of the wireless remote water meter for 8 years is: (511+44)=555*8=4440mAh. We consider using ER26500 in parallel with HPC1520 battery pack for power supply, with a nominal capacity of 8500mAh. Considering the discharge efficiency of the battery under low current in winter and high temperature in summer, we generally think that the effective rate of capacity is 80% (6800mAh).

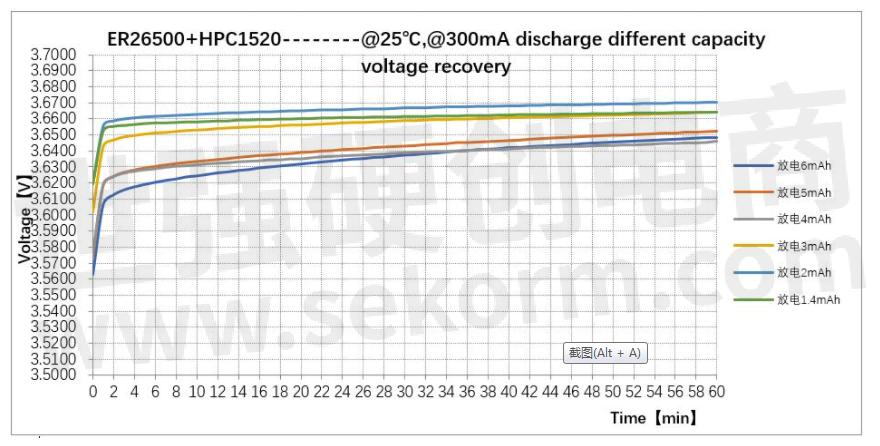

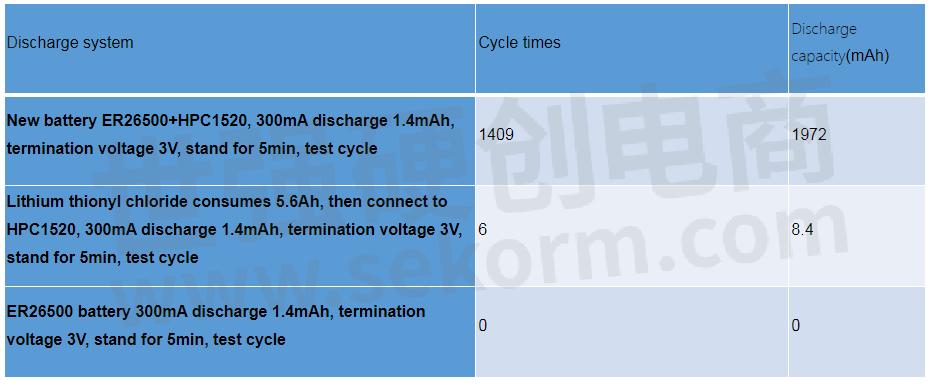

Taking into account the efficiency of HPC being charged by lithium thionyl chloride batteries, the following tests are made:

1. The battery pack releases different capacity and voltage recovery capabilities

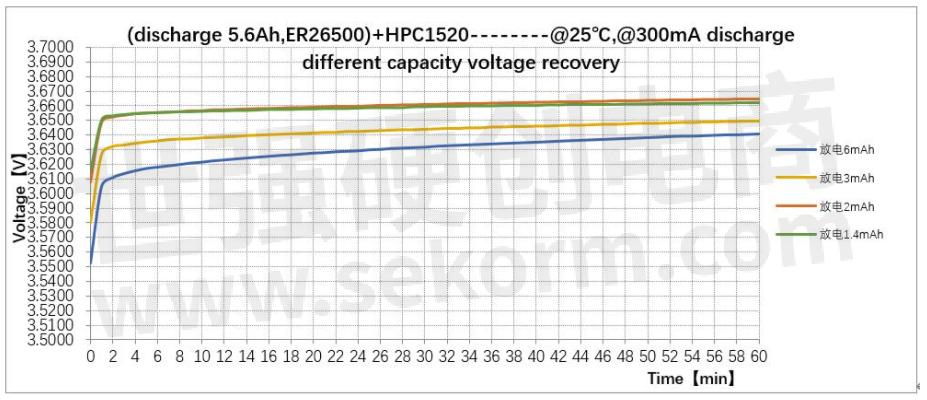

2. Simulate Lithium thionyl chloride battery ER26500 capacity consumption about 70% and then discharge voltage recovery

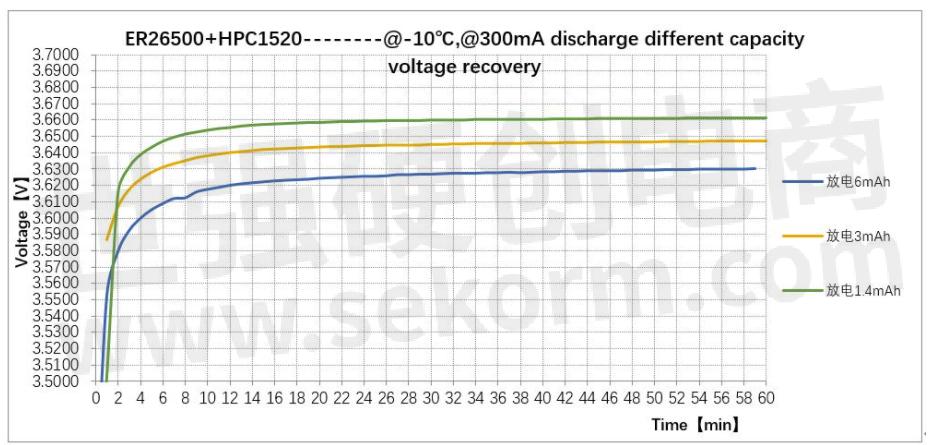

3. Recovery of discharge voltage under low temperature conditions:

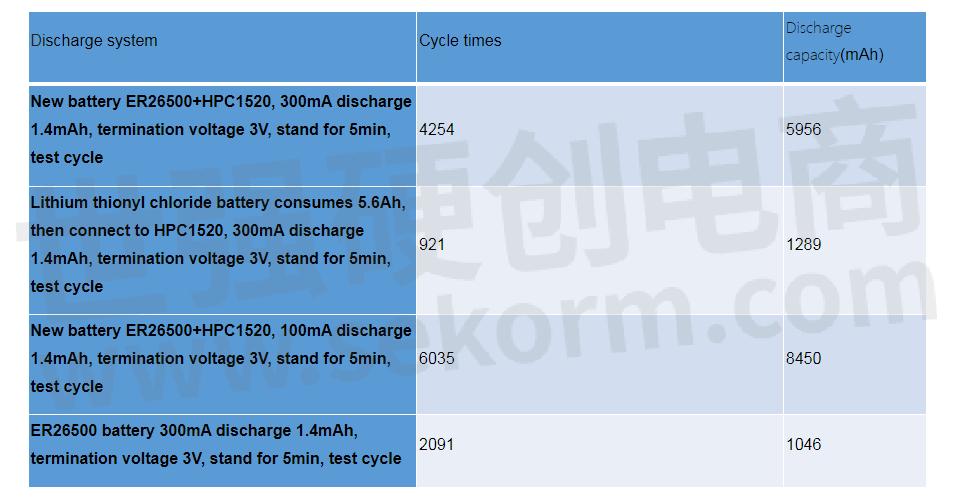

Taking into account the ability of the battery at peak current to make the following tests:

In order to figure out the usage characteristics of the battery, we set to speed up the working cycle, as shown in the following table:

Test at -10℃ at low temperature:

According to the characteristics of GSM remote water meter battery, the following design is made: The required capacity for 2 years is: (395+244+5374)=6013*2=12026mAh. We consider using ER34615 in parallel with HPC1550 and then connected in series to a 7.2V battery pack for power supply, with a nominal capacity of 19000mAh. Considering the discharge efficiency of the battery under low current in winter and high temperature in summer, we generally think that the effective rate of capacity is 80% (15200mAh). We installed the new battery pack and the battery pack with only 70% capacity of the lithium thionyl chloride battery ER34615 in parallel with HPC1550. The actual test was performed 100 times under extreme low temperature (-35℃), and the minimum working voltage of the equipment was maintained at 6V~6.5V. It can fully meet the power demand. The effective capacity of the entire battery pack can reach more than 13,300 mAh. It can fully meet the requirements of two years of equipment use.

According to the above test results, our IOT battery can fully meet the power demand of the water meter industry.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.