ATP Industrial Memory Cards Employ Sip Technology, Autorefresh and Dynamic Data Refresh Avert Read Disturb Errors And Data Corruption

Why Bigger or Faster isn't Always Better

Since their introduction in the 1990s, Memory Cards have remained among the most successful, trusted and low-cost storage solutions available. They are commonly used to store images, videos, audio and text in portable devices such as cameras and smartphones.

Because consumer memory cards cost lower and have become commonly used in numerous everyday applications, they are also often used for industrial purposes that they are not built for.

Consumer vs. Industrial: What is the difference?

Consumer products are intended for personal, family and non-business use. On the other hand, industrial products are intended for the design, manufacture, packaging, delivery and distribution of goods and services. As such, industrial-grade items such as memory cards require tough, reliable and high-quality components that can perform dependably over long periods of time to ensure maximum availability, minimal downtime, and better return on investment.

Industrial applications include:

Networking/Telecommunications

The Internet of Things (IoT)

Avionics

Automation

Enterprise Mobility

Health Care

Automotive Computing

Aerospace and Defense

Industrial/Embedded PC

Figure 1. Common industrial applications where memory cards are used

Important Industrial Requirements and Factors to Consider

Often, industrial applications are not only mission critical, but are also safety and life critical. As more and more industrial systems become autonomous or require little to no human intervention, the efficiency of data storage and the timely access, delivery and analysis of information have never been more crucial.

Customers in the industry sector make purchase decisions based on the total cost of a solution rather than immediate short-term costs. This is mainly because industrial requirements are vastly different from personal or consumer use. Let us take a look at special industrial requirements that consumer products may not be designed or built for. Here are some key considerations to guide you through your decision-making process:

1. Customization

When choosing an industrial storage device such as a memory card, one size does not fit all due to the diversity of industries and extensive range of usage scenarios. It is important to determine how the device will be used and for which specific applications.

As a value-added service, ATP Electronics offers customization options to better address customer requirements for specific markets and applications, such as pre-loading customer-consigned data and joint validation with client-supplied host devices and systems.

2. Reliability and Endurance

Will the memory card be used in harsh environments with variable temperature shifts? Industrial machines and road surveillance cameras, for example, operate for lengthy periods, often non-stop for 24 hours a day, 7 days a week. Tough operating scenarios expose the memory cards to elevated temperatures, vibrations, shocks, dust and other elements. Apart from continuous use, memory cards also undergo constant physical stress. Being small and portable, they are usually crammed in tiny spaces and have to be inserted and removed continually. They should be able to withstand rough usage without malfunctioning or compromising performance.

ATP industrial memory cards employ System in Package (SiP) technology, which encapsulates all exposed components, allowing the cards to withstand shock, vibration, dust, electromagnetic interference (EMI), electrostatic discharge (ESD), and variable weather conditions like extreme temperature and humidity.

ATP memory cards comply with SD Association's operating temperature specifications of -25℃ to 85℃, while select cards with industrial temperature (iTemp) rating can perform reliably under extremely cold to hot temperatures of -40°C to 85℃.

Figure 2. ATP SiP encapsulates all exposed components for better durability.

3. Data Integrity

When only certain blocks of the card are frequently read, read disturb errors can occur, resulting in errors that compromise data accuracy and integrity. A self-driving car with corrupted data in its memory card may fail to detect crossing pedestrians or ignore the risks of changing lanes, thus endangering the life and safety of people. Industrial memory cards should have powerful solutions to ensure data integrity especially for mission- and life-critical applications.

ATP AutoRefresh monitors the error bit level in every operation. Before the error bits in a block reach or exceed the preset threshold value, AutoRefresh moves the data to a healthy block, thus preventing the controller from reading blocks with too many error bits and averting read disturb errors and data corruption.

Dynamic Data Refresh, on the other hand, runs automatically in the background to reduce the risk of read disturbance and to sustain data integrity in seldom-accessed areas by sequentially scanning the user area flag record without affecting the read/write operation. The data that has been completely moved to another block will be read and compared with the source data to ensure data integrity.

Figure 3. ATP AutoRefresh and Dynamic Data Refresh avert read disturb errors and data corruption.

4. High Quality and Compliance with Industry Standards

Consumer memory cards may use lower-grade NAND flash or adopt the latest NAND processes to pursue cost advantages, which could compromise reliability and product life or result in low yield rate and unstable performance. In health care applications, for example, patient information is vital to diagnosis and treatment, and no margin of error resulting from poor quality is tolerable.

• ISO9001, ISO14001, ISO/TS16949

• IEC60529 (water/dustproof): SD - IP67; microSD – IP57

• Select AEC-Q100 test items and conditions

5. Capacity and Speed

Bigger and faster are not necessarily better. Some industrial applications do not need high capacities or fast performance. Determine how you will use the memory card and what types of files you need to store and process. ATP memory cards are available in different performance classes and densities utilizing both planar and 3D NAND flash technologies to meet different application requirements. Click here for an introduction to different memory card classes.

6. Compatibility

Physically, there's no distinguishable difference between consumer and industrial memory cards. A consumer card will fit in any system with the appropriate slot but may not work due to technical issues, so compatibility with host devices and specific applications should be taken into account. Often, firmware or settings customizations need to be done for specific applications.

Through the Joint Validation program, ATP conducts compatibility/function tests with client-supplied host devices and systems to proactively detect and minimize failures that may not be caught in production tests.

Figure 4. Under the Joint Validation Program, ATP conducts tests using client-supplied host devices and systems.

7. Power Failure Protection

Even a minor power disruption can have a devastating impact on critical industrial applications, whether for safety or business reasons. It is therefore important for data to be protected against sudden power losses.

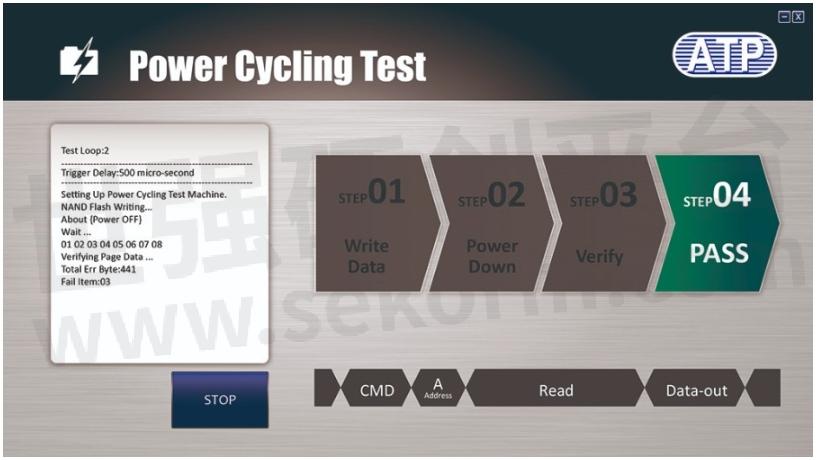

The Sudden Power-Off Recovery (SPOR) firmware backup mechanism ensures data integrity and reliable operation even during power supply voltage fluctuations and frequent power losses. Verified by ATP-developed power cycling tests and random power-off in write applications, SPOR effectively traces and recovers previous valid data when power comes back on.

Figure 5. Verified by ATP's stringent power cycling test platform, SPOR minimizes the risks of a sudden power loss. (Image is for reference only. Actual screen may vary.)

8. SD Health/Life Monitoring*

Flash can be written to only for a finite number of times. Being caught off guard with the memory cards' sudden end of life can have disastrous effects. ATP memory cards allow easy real-time monitoring of the health status and life expectancy of ATP memory cards. SD Life Monitor provides a user-friendly interface that monitors wear-and-tear parameters such as erase count, bad block count, spare block count, and remaining life, so unexpected data loss can be prevented when the flash memory nears or reaches its end life and device replacement plans can be made well ahead of time.

* Compatibility and support may vary by platform or operating system.

ATP Competencies

To date, there is really no definitive standard for identifying a memory card as "industrial grade." Typically, manufacturers will tout their products as industrial grade if they can withstand wide operating temperature ranges of -40℃ to 85℃, or if they employ single-level cell (SLC) NAND flash.

While these are important considerations, ATP recognizes that with the wide array of industrial usage applications along with the unique industrial requirements listed above, the "industrial" label should go beyond product specifications or capabilities.

Industrial memory cards from ATP are constructed specifically for mission-critical as well as safety- and life-critical applications in a wide spectrum of usages. Whether they are for connected automobiles, smart factories, intelligent homes or buildings, or rugged environments and terrains, these tough memory cards can be trusted for long, dependable use under varied workloads and scenarios.

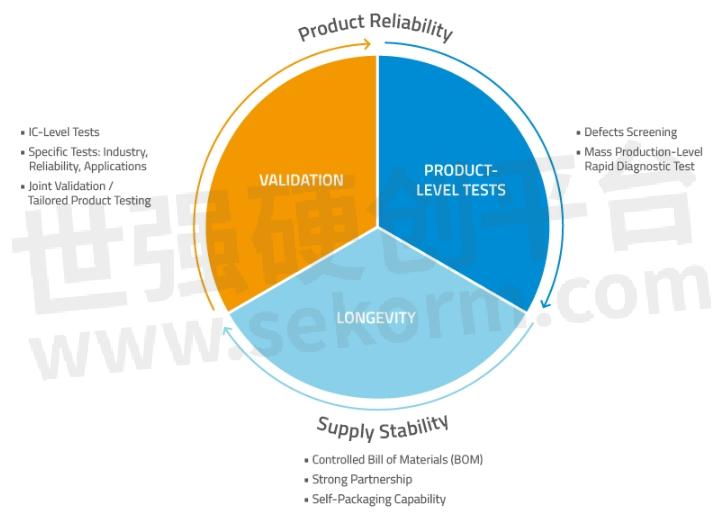

By ATP's definition, "industrial grade" covers both Product Reliability as well as Supply Stability. The components of a true industrial grade product are discussed below.

Product Reliability

Validation

ATP conducts full-scale IC-level tests to screen out weak ICs and enhance IC-level reliability. Specific reliability tests include temperature (extreme high and low temperature; temperature cycling), electrostatic discharge (ESD), electromagnetic interference (EMI), dust, humidity, shock/vibration. Industry-standard compliances include JEDEC, MIL-STD 810G, AEC-Q100 ISO and more. Under the Joint Validation Program, ATP conducts tests using client-supplied host devices and systems to ensure compatibility

Product-Level Tests

Manufacturing/component defects are screened out before shipment through product-level tests like 100% copy-compare and burn-in tests. Rapid Diagnostic Test includes testing at iTemp range (-40℃ to 85℃), block-by-block testing for complete coverage including spare areas, and stricter testing criteria settings to ensure the reliability of ATP memory cards.

Supply Stability

Industrial applications require sustainable solutions and long product cycles. Memory cards for industrial applications should have product cycles of at least 5 years.

ATP's strategic partnerships with leading suppliers ensure long-term bill of materials (BOM) and supply stability. By implementing dual-sourcing strategy and controlled BOM, ATP guarantees long product cycles with buffer inventory. Any changes affecting the process or product are communicated to the customer. Additionally, with ATP's NAND self-packaging capability and validation, every memory card is backed by ATP's extensive manufacturing expertise that spans 25 years.

- +1 Like

- Add to Favorites

Recommend

- A Tutorial Guide on Selecting the Right SD Card: SD Card Symbols, Classes, and Compatibility Deciphered

- The Difference between SIM Card and SD Card

- SMART‘s DuraFlash, High-capacity, RD230 SD Cards are Fully SD UHS-I Compliant

- SD Performance Standards

- Moving Health Forward with SD Cards

- Embedded MultiMediaCards (eMMCs) vs. Secure Digital (SD) Cards

- SMART‘s DuraFlash, High-capacity, RD230m MicroSD Cards are Fully UHS-I Compliant

- More Compact, Low-cost Type Standard Specification SD Card Connector CIM-K03N/CIM-K03NS/CIM-K10R/CIM-K09RS

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.