How to Master EV Charging Components Testing - Chroma Can Help!

Shortening the battery charging time while improving its safety has become one of the most important topics in the industry. During AC charging, the on-board charger (OBC) plays a key role and, currently, OBC power range varies with each new vehicle model. For example, the power range of a plug-in hybrid electric vehicle (PHEV) and a battery electric vehicle (BEV) is within 3.3kW and 6.6kW respectively with maximum 350V~700V output voltage. In the meantime, the development of new technology is focused on increasing OBC power density, integrating the DC-DC converter, and adding new inverter functions (V2G/V2L/V2V). While 6.6kW is limited to single-phase AC power, we are seeing new products with power increased to 20kW three-phase.

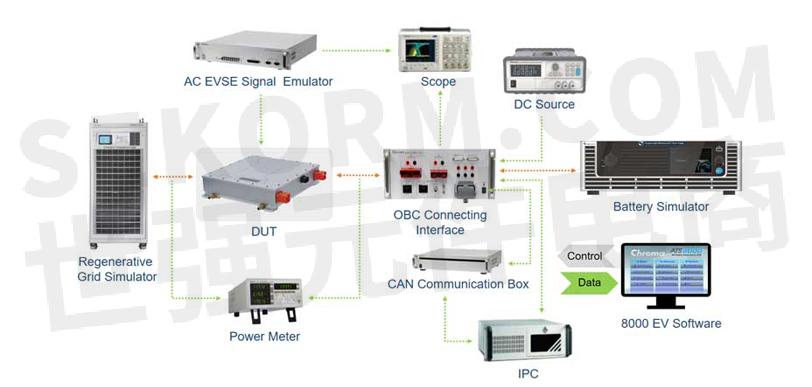

For the basic required test items such as calibration test, performance test and protection function in the OBC production line, CHROMA's automated test platform can simulate the limit conditions testing of voltage/current/CP signals or other failure conditions. Main features include:

1.Simulating AC EVSE output signal or power grid abnormal

2.Simulating EV CANBUS signal and battery pack charging status

3.Providing bidirectional OBC (BOBC) test requirements

4.Supporting 2-in-1 model (OBC+DCDC) integration test

5.Programmable open source software platform for users to program test items as desired and upload test reports to MES automatically.

With built-in test items conforming to QC/T895 and GB/T 24347 standards, on-board charger and DC/DC converter test solutions by Chroma have been widely used in the EV industry to meet diverse testing needs. More than 40 types of test items are provided to verify the product performance, environmental adaptability and reliability for the quality inspection required by government and third-party laboratories. They can be applied to car manufacturers and parts suppliers as well for product specification validation or incoming quality control of material. Chroma's test solution is able to be customized and is equipped with BOBC test platform capabilities. BOBC is one of the essential components for electric vehicles to feed power back to the grid (V2G). V2G technology not only alleviates the power pressure of grid spikes, but also helps the distribution of microgrid power in remote areas. According to industry reports, standardized communication interfaces and good testing environment are the keys to the future success of V2G.

▲Structure of Chroma Onboard Charger Test System

Chroma provides significant comprehensive test solutions to the EV industry for R&D, incoming inspection, mass production, and the entire vehicle's upstream and downstream processing.

- +1 Like

- Add to Favorites

Recommend

- Chroma Launches Next-Generation High-Performance Power IC Test Platform Chroma 3650-S2 Equipped with up to 768 pins, 200Mbps data rate

- Sekorm Became an Official Authorized Distributor of Chroma

- Chroma Regenerative Test Solutions Accelerate Net-Zero Transition

- Chroma ATE Inc. Featured in Forbes Asia‘s Best Under A Billion 2023, Showcasing Consistent Top- and Bottom-Line Growth

- 8610 Battery Pack Integrated Testbed for Testing New Energy Vehicle Battery Systems and Subparts | Chroma

- Chroma ATE Showcases Advanced Test Technology to Propel the AI Revolution at SEMICON Taiwan 2023

- Chroma 62000d Programmable Bidirectional Dc Power Supplies Have Both Power Source and Load Characteristics

- Chroma Test Setup for Complete Gamma Measurement on Video Signal Generators

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.