Flexible Interface of the ZSSC3241 Enhanced Sensor Signal Conditioner Enables Bridge as Temperature Sensor

Accurate measurement using sensor elements requires precise and local measurement of the element’s temperature for correction and compensation across a wide operating range. Therefore, an integral part of Sensor Signal Conditioner (SSC) functionality is to provide one or more methods to measure the temperature of the sensor element, which is typically a resistive bridge or capacitive transducer.

Often, the sensor element may be separated from the SSC by several centimeters or more. In these cases, an SSC cannot be used predictably for temperature compensation and some type of external thermometer is needed that can be co-located with the bridge sensor.

For resistive bridges, the ultimate way to measure the sensor temperature accurately with no additional cost or space is to use the temperature coefficient of the bridge itself. But this requires further complexity in the biasing circuitry for the sensor bridge as well as more sophisticated calibration algorithms in the SSC to linearize the temperature coefficient of the bridge (which may exhibit up to third-order variation).

With the ZSSC3241 Enhanced Sensor Signal Conditioner, the ability to use the temperature coefficient of the bridge for accurate sensor temperature measurement is fully integrated and supported.

Flexible Temperature Measurement with the ZSSC3241 High-End SSC

The SSC can support temperature measurement using an internal PTAT, external diodes, or thermistors, and using the main sensing bridge itself as the thermometer. The various options are fully programmable and configurable using internal Non-Volatile Memory (NVM) for optimal performance based on system requirements.

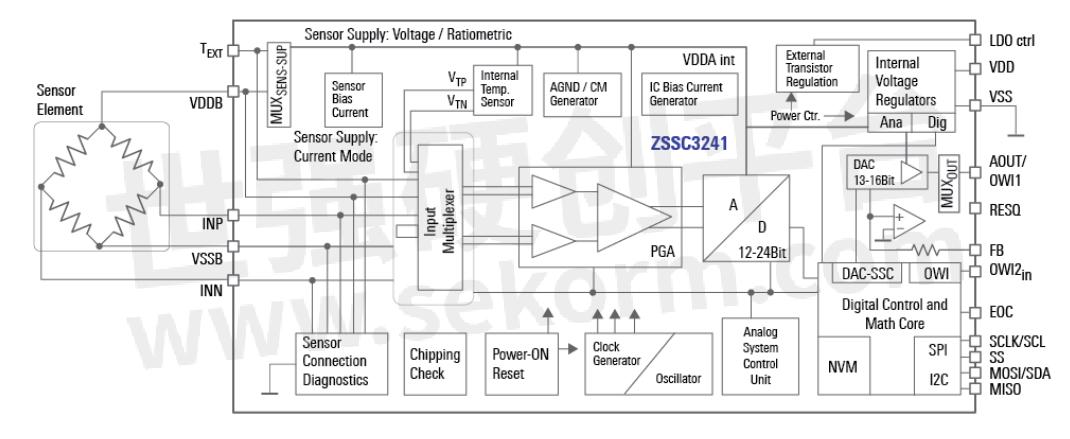

The basic block diagram for the ZSSC3241 shows the configurable sensor interface with biasing and amplification functions in the analog front end. There is also an Internal Temperature Sensor onboard. The ADC converts the sensor and temperature readings into the digital domain, where all the linearization, correction, and temperature compensation functions are performed. The final calibrated and scaled outputs are available as either analog or various digital representations.

Figure 1. Block Diagram of the ZSSC3241 Sensor Signal Conditioner (SSC).

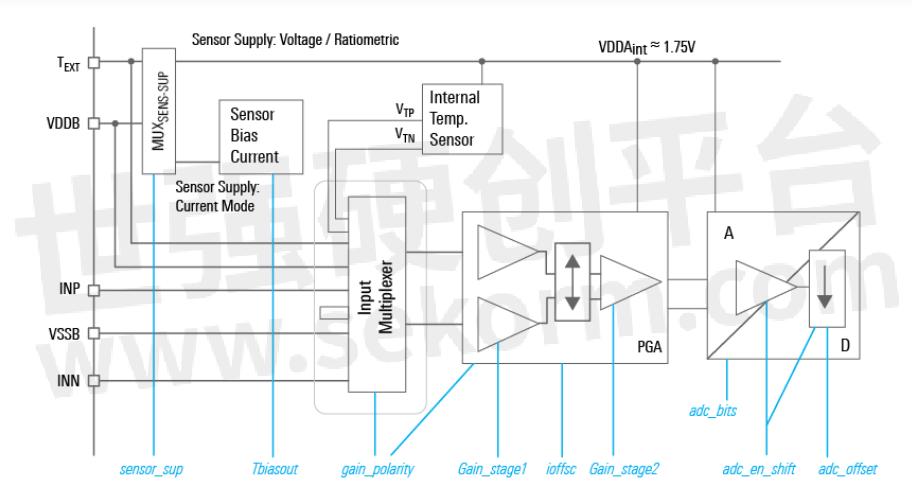

A close look into the analog front end shows there are four blocks in particular that enable the ZSSC3241 to reconfigure temperature measurements: a sensor-supply multiplexer to switch between current and voltage bias modes, a sensor bias current source, an internal temperature sensor, and an input multiplexer that selects between the measurands. These blocks are controlled by bits in the NVM labeled sensor_sup, Tbiasout, and gain_polarity.

Figure 2. Configurable blocks of the Analog Front End interface to the bridge and temperature sensors.

The ZSSC3241 provides 7 different temperature measurement modes

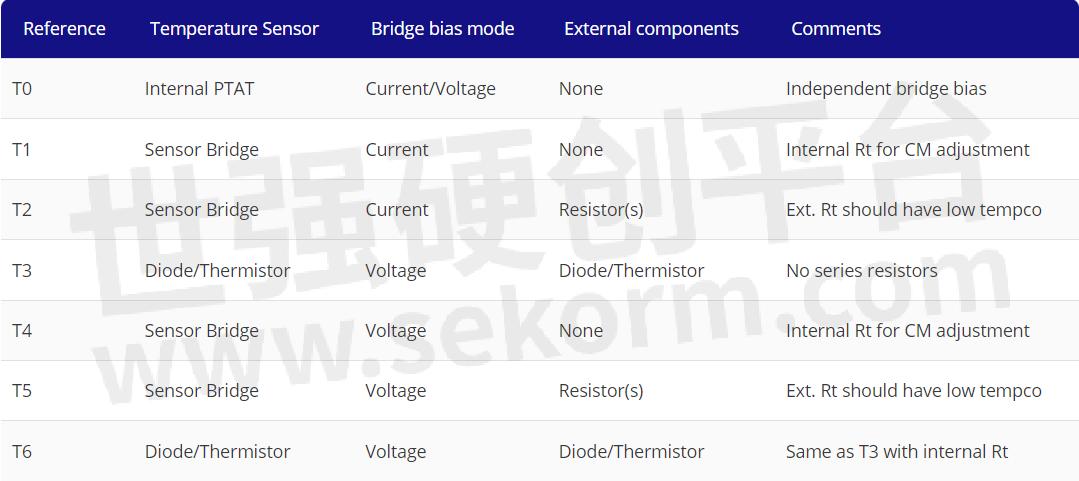

With these blocks and the configuration options, the ZSSC3241 provides 7 different temperature measurement modes as summarized in the table below. There are two primary biasing modes for using the sensor bridge as a thermometer: current and voltage. For each of these types, a series resistor, Rt, is required to adjust the common mode voltage of the bridge into the proper range for the internal Programmable Gain Amplifier (PGA). The ZSSC3241 provides the option to have this series resistance fully integrated for many cases, but some external resistance might be required in cases where accuracy requirements are stringent.

Table 1. Summary of Temperature sensing options in the ZSSC3241. The references T1-T6 correspond to labels used in the datasheet.

With its wide range of front-end configurations, the ZSSC3241 enables designers to optimize both the main sensor interface and the type and location of sensors used for temperature compensation, achieving the best accuracy possible with fewer components and costs.

- +1 Like

- Add to Favorites

Recommend

- Renesas‘s ZSSC3281 Sensor Signal Conditioning IC:A Quantum Leap in Sensor Signal Conditioning

- Renesas DSP Solution on Renesas Lab on the Cloud, Input Analog Signals Directly From A Signal Generator To The Rx231 Microcontroller Evaluation Board

- Renesas‘ Semiconductor Manufacturing Factory (Naka Factory) Fire: Production Capacity Has Recovered to 88%

- Renesas Announces 10 New Winning Combinations Integrating Celeno and Renesas Products

- Renesas & Altran to Deploy First Social Distancing Wristwatch Using Ultra-Wideband Chipset with Low Rate Pulse

- Renesas and FAW Establish Joint Laboratory to Accelerate Development of Next-Generation Smart Vehicles

- Renesas Semiconductor Manufacturing Factory (Naka Factory)‘ Production Level Has Returned to 100%

- The Zssc3240 Sensor Signal Conditioner with Integrated Sensor Diagnostics and Industry-proven Interfaces

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.