ATP AcuCurrent: Innovative Signal Integrity Optimization Technology

Today's SSDs face complex challenges, such as extreme temperature shifts and harsh environmental conditions, along with a multitude of other complex interplays such as controller, power, integrated circuits (ICs), microcontroller units (MCUs), NAND configuration, and more.

Signal integrity is essential for SSD performance and dependability. It ensures reliable data transfer and storage. By lowering the possibility of needless read-retry cycles and significantly lowering error rates, ideal signal integrity enhances data throughput and dependability. This is especially crucial in industrial settings where temperature fluctuations may present additional challenges for SSDs.

Typically, SSD settings are static or fixed. With all the aforementioned complexities of SSD operation that are constantly changing, static settings no longer suffice. How can SSDs ensure optimal signal integrity to enhance their performance and reliability amidst different environments and varying temperatures?

ATP AcuCurrent Technology: Ensuring Optimal Signal Integrity in Any Scenario

Expecting conventional, static SSD settings to tackle diverse environmental conditions is becoming increasingly unreasonable. ATP's AcuCurrent Technology is an innovative signal optimization technology, enabling dynamic, real-time temperature-responsive drive setting adjustments across a wide operating range, up to 125℃. ATP leverages its expertise developed over years of research in firmware and power IC/MCU mechanisms to develop an innovative solution that considers all the complex factors mentioned. AcuCurrent Technology is temperature-responsive, dynamically adjusting settings in real time to ensure that the SSD operates at great efficiency across various scenarios, effectively minimizing unnecessary read-retry cycles, and substantially reducing error rates.

Complex Challenges

Scenario 1: Low Temperature Causes Boot Failure in the Railway System

Modern railway transport infrastructures rely on solid-state drives to boot up train sub-systems and store huge amounts of data that provide real-time train-related information to passengers and help railway staff manage trains. The reliability of the SSD and its prompt readiness in accessing the stored data and operating system are paramount to the efficient operation of the railway system.

The Challenge:

When not in use, the train is parked in a yard without temperature conditioning and is expected to power on just before service hours. During certain seasons and extreme weather conditions, the SSD is unable to boot up due to low temperatures on the premises. There is no time for the operator to warm up the system. The SSD is expected to boot up within its operating temperature range.

The AcuCurrent Solution:

AcuCurrent's temperature-responsive current adjustments ensure stable performance across a wide operating range, up to 125°C. This feature is particularly important during the boot-up sequence, whereas conventional firmware algorithms only engage during operation

Scenario 2: Unmanaged Heat Leads to Production Slowdowns

In manufacturing facilities, SSDs play an important role in the production communication and monitoring system.

The Challenge:

Air conditioning sometimes does not suffice due to the complex machinery setup that generates heat unevenly inside the facility. This prevents the system from cooling down through ambient airflow. Occasionally, the SSD may be operating at an ambient temperature of around 60℃ inside the system, thus risking damage to the device itself and increasing errors to the data stored in it. The unmanaged heat can lead to abnormal system slowdowns, even when not writing a heavy amount of data. Such slowdowns interrupt other related equipment, causing pauses in production and creating a chain reaction that delays overall production efficiency. The SSD attempts error correction but this leads to an increase in read retry counts and bad blocks beyond its expected lifespan.

The AcuCurrent Solution:

AcuCurrent enhances performance efficiency by minimizing unnecessary read-retry operations, resulting in faster and more effective data access processes. The system no longer experiences abnormal slowdowns, with observable read retry counts substantially reduced.

Benefits

ATP's AcuCurrent Technology offers the following benefits:

Product Lifetime Fortification: AcuCurrent fortifies product lifetime and reliability by dynamically adjusting current based on temperature variations, minimizing errors and unnecessary read retries, thus potentially reducing bad block counts and preserving spare blocks.

Enhanced Performance Efficiency: AcuCurrent enhances performance efficiency by minimizing unnecessary read-retry operations, resulting in faster and more effective data access processes.

125℃ Temperature Operational Range Resilience: AcuCurrent's temperature-responsive current adjustments ensure stable performance across a wide range of operating range up to 125℃, enhancing the SSD's resilience to environmental temperature variations.

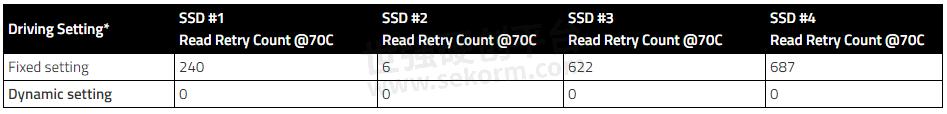

The following table illustrates how AcuCurrent Technology optimizes signal integrity, and thus substantially decreases, read retry counts in ATP's PCIe® Gen4 NVMe E1.S SSD.

Conclusion

Static settings are no longer enough to ensure optimal integrity in the face of temperature fluctuations, varying environmental conditions, and other operational challenges. The AcuCurrent Technology offers dynamic, temperature-responsive, and real-time adjustments to ensure that the SSD performs reliably in any setting.

- +1 Like

- Add to Favorites

Recommend

- News | NAND Flash Storage Solutions for the Data-Driven 5G Era | ATP

- ATP Rapid Diagnostic Test (RDT): Accelerating Failure to Maximize Reliability and Endurance

- ATP Electronics’ Latest pSLC Embedded SSDs Offer Best TCO with Customizable Endurance

- ATP Launches Its Tiniest PCIe Gen3 x4 NVMe™ SSDs in M.2 Type 1620 HSBGA Package

- ATP Electronics Launches Industrial 176-Layer PCIe® Gen 4 x4 M.2, U.2 SSDs Offering Excellent R/W Performance, 7.68TB Capacity

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.