What is Floating Board To Board Connector ?

1.What is the size, current and voltage rating of this connector?

The Floating Board To Board Connector is a versatile and widely used component in the electronics industry. It is designed to establish connections between circuit boards, allowing for the transmission of signals and power between them. Here is a comprehensive introduction to the Floating Board To Board Connector, including its size, current rating, and voltage rating.

Size: The Floating Board To Board Connector comes in various sizes to accommodate different application requirements. It is available in different pitch sizes, typically ranging from 0.5mm to 2.54mm. The pitch size refers to the distance between adjacent pins or contacts on the connector. The connector's overall dimensions may vary depending on the specific model and configuration.

Current Rating: The Floating Board To Board Connector is designed to handle different levels of current, depending on the specific model and configuration. The current rating of the connector is determined by factors such as the size and material of the contact pins, the contact resistance, and the temperature rise. Generally, the current rating can range from a few milliamps to several amps, allowing for a wide range of applications.

Voltage Rating: The Floating Board To Board Connector is designed to withstand specific levels of voltage without insulation breakdown or arcing. The voltage rating of the connector is determined by factors such as the dielectric strength of the materials used, the spacing between contacts, and the design of the insulation. The voltage rating can vary depending on the specific model and configuration, ranging from a few volts to several hundred volts.

It is important to note that the size, current rating, and voltage rating of the Floating Board To Board Connector may vary depending on the manufacturer and specific product series. It is essential to consult the product datasheet or contact the manufacturer for detailed specifications and ratings for a specific connector model.

In conclusion, the Floating Board To Board Connector is a versatile component used for establishing connections between circuit boards. Its size, current rating, and voltage rating may vary depending on the specific model and configuration. The connector's specifications determine its compatibility with different applications, and it is crucial to consider these factors when selecting and using the Floating Board To Board Connector in electronic designs.

2. Are there different socket types to choose from?

Floating Board to Board Connectors are available in a variety of socket types to cater to different application requirements and design preferences. These socket types offer unique features and advantages, allowing designers to select the most suitable option for their specific needs. Here is a comprehensive overview of the different socket types available for Floating Board To Board Connectors:

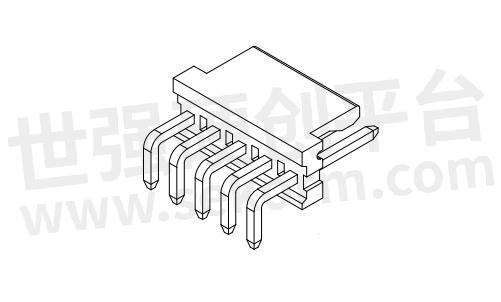

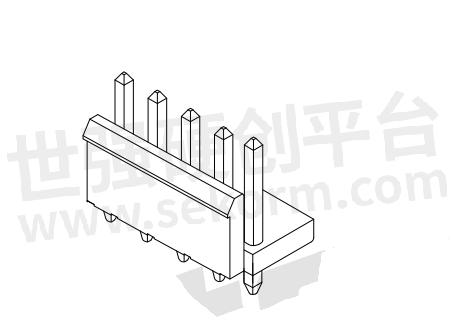

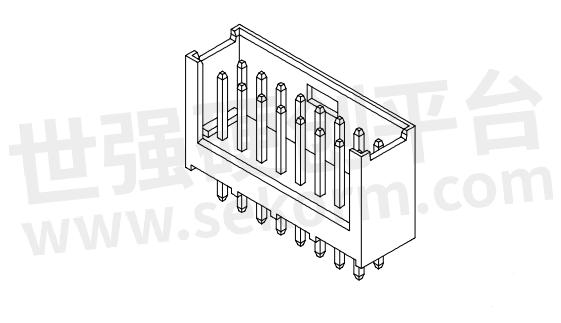

Standard Socket: The standard socket type is the most common option for Floating Board To Board Connectors. It features a simple design with straight pins or contacts that provide a secure and reliable connection between circuit boards. Standard sockets are available in various pitch sizes to accommodate different spacing requirements between boards.

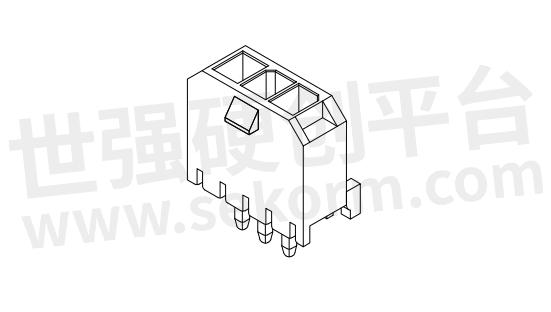

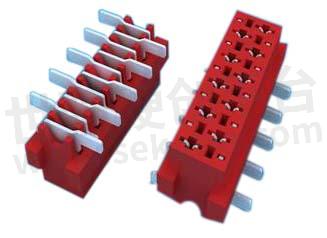

SMT Socket: Surface Mount Technology (SMT) sockets are designed for easy and efficient surface mounting on the circuit board. These sockets have solder pads instead of through-hole pins, allowing for automated assembly processes and saving space on the board. SMT sockets provide a low-profile solution for compact electronic designs.

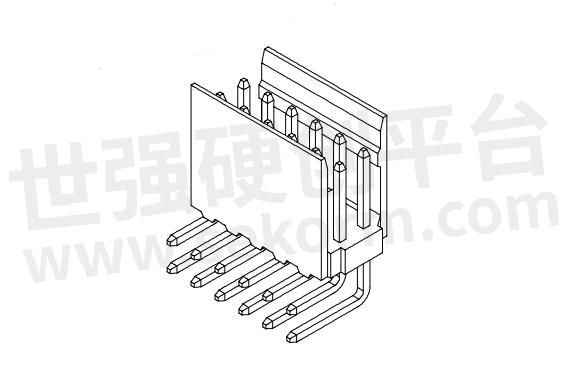

Right-Angle Socket: Right-angle sockets are designed to create connections between circuit boards at a right angle. This configuration is useful when space constraints or specific board orientations require a perpendicular mating arrangement. Right-angle sockets ensure a secure connection while optimizing the use of available board space.

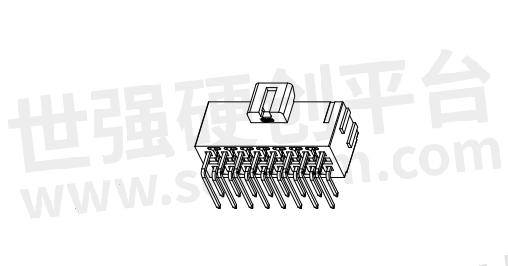

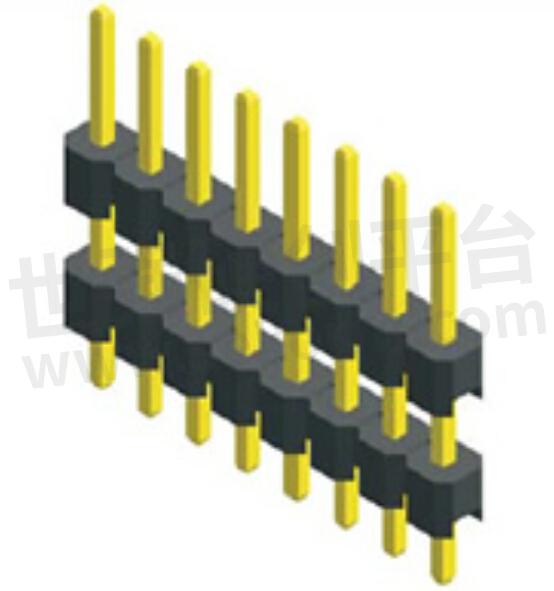

Stacked Socket: Stacked sockets feature multiple rows of contacts stacked on top of each other. This design allows for higher-density connections between boards, enabling designers to maximize the number of connections in a limited space. Stacked sockets are ideal for applications that require a high number of signal paths or data lines.

Floating Socket: Floating sockets provide a degree of freedom in the lateral movement of the connected boards. This flexibility compensates for any misalignment or thermal expansion between the boards, ensuring a reliable and stable connection. Floating sockets are suitable for applications where board alignment may vary due to mechanical stress or temperature fluctuations.

High-Speed Socket: High-speed sockets are designed to support high-frequency signal transmission between boards. These sockets feature optimized signal integrity characteristics, such as controlled impedance and reduced crosstalk, to maintain signal integrity in high-speed data transfers. High-speed sockets are ideal for applications that require reliable data communication at high data rates.

In conclusion, Floating Board To Board Connectors offer a range of socket types to suit different design requirements, including standard, SMT, right-angle, stacked, floating, and high-speed sockets. Designers can choose the appropriate socket type based on factors such as space constraints, alignment needs, signal integrity requirements, and ease of assembly. Selecting the right socket type is essential to ensure a successful and efficient board-to-board connection in electronic designs.

3.Main purposes and application areas

Floating Board To Board Connectors are widely used in various industries and applications where the establishment of reliable and secure connections between circuit boards is crucial. Here is a comprehensive overview of the main purposes and application areas of Floating Board To Board Connectors:

Consumer Electronics: Floating Board To Board Connectors are extensively used in consumer electronics devices such as smartphones, tablets, laptops, and gaming consoles. These connectors enable the interconnection of different circuit boards within these devices, facilitating the transmission of signals and power.

Automotive: Automotive applications require robust and reliable connectors to ensure the proper functioning of various electronic components. Floating Board To Board Connectors are utilized in automotive systems for applications such as infotainment systems, dashboard displays, advanced driver-assistance systems (ADAS), and engine control units (ECU).

Industrial Equipment: Floating Board To Board Connectors find application in industrial equipment and machinery, where they enable the connection of control boards, sensors, and actuators. These connectors are commonly used in robotics, automation systems, machine vision systems, and control panels.

Telecommunications: Floating Board To Board Connectors play a vital role in the telecommunications industry, providing connectivity solutions for network equipment, switches, routers, and base stations. These connectors ensure reliable data transmission and signal integrity in high-speed and high-frequency telecommunications applications.

Medical Devices: Medical devices require connectors that can withstand harsh environments and ensure secure connections. Floating Board To Board Connectors are used in medical equipment such as patient monitoring systems, imaging equipment, diagnostic devices, and surgical instruments. They provide the necessary connectivity for the proper functioning of these critical devices.

Aerospace and Defense: Floating Board To Board Connectors are utilized in aerospace and defense applications where high reliability and ruggedness are required. These connectors are used in avionics systems, satellite communication systems, military vehicles, and radar systems.

LED Lighting: Floating Board To Board Connectors are employed in LED lighting applications, connecting LED driver boards to LED modules or strips. These connectors enable the transmission of power and control signals, ensuring efficient and reliable operation of LED lighting systems.

Renewable Energy: Floating Board To Board Connectors are used in renewable energy systems such as solar power and wind power generation. These connectors facilitate the interconnection of control boards and power electronics, enabling efficient energy conversion and management.

In conclusion, Floating Board To Board Connectors have a wide range of applications in various industries, including consumer electronics, automotive, industrial equipment, telecommunications, medical devices, aerospace and defense, LED lighting, and renewable energy. These connectors play a crucial role in establishing reliable connections between circuit boards, ensuring the proper functioning of electronic systems and devices.

4. How durable and reliable is it?

Floating Board To Board Connectors are known for their durability and reliability, making them a popular choice for various electronic applications. Here is a comprehensive description of the durability and reliability features of Floating Board To Board Connectors:

Materials: Floating Board To Board Connectors are typically manufactured using high-quality materials such as stainless steel, phosphor bronze, and high-temperature resistant plastics. These materials offer excellent durability, ensuring the connectors can withstand mechanical stress, temperature variations, and environmental factors.

Contact Design: Floating Board To Board Connectors feature well-designed contact points that provide a secure and reliable connection. The contact pins or pads are often plated with materials such as gold or palladium to enhance their conductivity and corrosion resistance. This ensures a long-lasting and reliable connection between the boards.

Shock and Vibration Resistance: Floating Board To Board Connectors are designed to withstand shock and vibration, which are common occurrences in many applications. The connectors often have features such as locking mechanisms or additional support structures to prevent accidental disconnection due to external forces.

Environmental Resistance: Floating Board To Board Connectors are engineered to resist various environmental factors such as moisture, dust, and chemicals. They may have sealing features or use materials that provide protection against these elements, ensuring reliable performance even in challenging environments.

Lifecycle and Durability Testing: Manufacturers subject Floating Board To Board Connectors to extensive lifecycle and durability testing to ensure their performance under real-world conditions. These tests simulate repeated mating and unmating cycles, temperature variations, and exposure to different environmental factors. Connectors that pass these tests are considered highly durable and reliable.

Quality Control: Floating Board To Board Connectors undergo strict quality control measures during their manufacturing process. Manufacturers often implement stringent quality assurance practices such as ISO certifications and in-house testing procedures to ensure the connectors meet industry standards and customer expectations.

Industry Compliance: Floating Board To Board Connectors are designed and manufactured to comply with industry standards and regulations. Compliance with standards such as UL, RoHS, and REACH ensures that the connectors are safe, reliable, and environmentally friendly.

In conclusion, Floating Board To Board Connectors are known for their durability and reliability. They are designed using high-quality materials, feature well-engineered contact points, and undergo rigorous testing and quality control measures. These connectors can withstand mechanical stress, temperature variations, shock, vibration, and environmental factors, providing a long-lasting and secure connection between circuit boards.

5. How does it work?

Floating Board To Board Connectors work by providing a secure and reliable electrical connection between two circuit boards. These connectors consist of two main components: the socket, which is attached to one circuit board, and the header, which is attached to the other circuit board.

The socket and header are designed to fit together, creating a mating interface for the connection. The socket typically has a series of pins or contacts, while the header has corresponding slots or receptacles. When the socket and header are properly aligned, the pins or contacts on the socket make contact with the slots or receptacles on the header, creating an electrical pathway between the two circuit boards.

The pins or contacts on the socket are usually spring-loaded, allowing for a certain degree of movement or float. This float enables the connectors to compensate for any misalignment or thermal expansion between the circuit boards. It helps maintain a reliable and stable connection, even in dynamic or changing conditions.

To establish the connection, the circuit boards are aligned and brought together, allowing the pins or contacts on the socket to enter the slots or receptacles on the header. Once the connection is made, the pins or contacts exert a force on the slots or receptacles, ensuring a secure and stable electrical connection.

Floating Board To Board Connectors can be used in various applications, such as consumer electronics, automotive systems, industrial equipment, telecommunications, medical devices, aerospace and defense, LED lighting, and renewable energy. The connectors are designed to accommodate different spacing requirements, orientations, and signal integrity needs, depending on the specific application.

In summary, Floating Board To Board Connectors work by providing a reliable and secure electrical connection between two circuit boards. They use spring-loaded pins or contacts to establish the connection and allow for a certain degree of movement or float to compensate for misalignment or thermal expansion. These connectors play a crucial role in enabling the seamless integration and functioning of electronic devices and systems.

6. How to install and use?

Installing and using Floating Board To Board Connectors is a straightforward process that requires careful attention to ensure a proper and secure connection. Here are the steps to install and use Floating Board To Board Connectors:

Preparation: Before installing the connectors, ensure that the circuit boards are clean and free from any debris or contaminants. This will help to establish a reliable and stable connection.

Connector Selection: Choose the appropriate Floating Board To Board Connector for your specific application. Consider factors such as pitch, orientation, and the number of contacts required.

Aligning the Connector: Place the socket connector on one circuit board and the header connector on the other circuit board. Make sure the connectors are properly aligned, ensuring that the pins or contacts on the socket line up with the slots or receptacles on the header.

Connection: Gently press the two circuit boards together, allowing the pins or contacts on the socket to enter the slots or receptacles on the header. Apply even pressure to ensure a secure and reliable connection. If necessary, use a magnifying glass or microscope to verify that all pins or contacts are properly aligned and inserted.

Locking Mechanism: Some Floating Board To Board Connectors feature locking mechanisms to provide additional stability and prevent accidental disconnection. If your connector has a locking feature, engage it according to the manufacturer's instructions.

Testing: Once the connection is established, test the electrical continuity and signal integrity between the circuit boards using appropriate testing equipment. This will help to ensure that the connection is reliable and that there are no issues with signal transmission.

Regular Inspection: It is important to regularly inspect the connectors for any signs of damage or wear. Check for loose pins or contacts, bent or broken parts, or any other abnormalities. If any issues are found, replace the connectors to maintain a reliable connection.

Removal: When removing Floating Board To Board Connectors, use caution to avoid damaging the circuit boards or the connectors themselves. Gently separate the two circuit boards, ensuring that no excessive force is applied.

In conclusion, installing and using Floating Board To Board Connectors involves aligning the connectors, pressing the circuit boards together, and ensuring a secure connection. Regular inspection and testing are essential to maintain the reliability of the connection. By following these steps, you can successfully install and use Floating Board To Board Connectors in various electronic applications.

- +1 Like

- Add to Favorites

Recommend

- Greenconn New Launches GGAC203/CGAC203 Series Floating Board to Board Connectors with Stacking Heights of 20mm and 15mm

- KYOCERA Launches a New 0.5mm-pitch Floating Board-to-board Connector for High-speed 16gbps Data Transmission

- Greenconn Launched Various Series of Floating Board-to-Board Connectors,Which Have Been Widely Used in Display Screens Applications

- The Benefits of Floating Connectors

- Kyocera‘s Floating Connectors Achieve Both Compact and Highly Mobile Floating Structures and High-speed Transmission

- Greenconn’s GC01 Series Floating BTB Connectors Enable Enhanced High-speed, High-current Transmission

- XYZ Axes Floating BTB Connectors, Flexible to Achieve Refined and Miniaturized Layout

- How Much Do You Know About Floating Connectors?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.