Application of Industrial Computers in Industrial AI Defect Detection Systems

Artificial Intelligence (AI) technology is increasingly widely used in the industrial field, of which the defect detection system is an important application direction. Traditional industrial quality inspection often relies on manual visual inspection, there are problems such as low efficiency, high cost, unstable accuracy, etc., and the introduction of AI technology defect detection system can fully enable industrial quality inspection, intelligent production, improve production efficiency and product quality, and promote the upgrading of industrial industry.

A technology company founded in 2015, with "machine vision algorithm" as the core, focusing on machine vision, motion control, AI inspection technology, industrial vision components and industry solutions. Its products are mainly used in 3C electronic manufacturing, new energy, semiconductor, automotive, logistics, food and textile, etc., which comprehensively empowers the industrial quality inspection and industrial intelligent industrial upgrading. Recently, the company's newly developed industrial AI inspection system series, adopted our VMC-1000 industrial computer.

VMC-1000 industrial pc is equipped with a Core processor for high-performance visual computing and analysis. Equipped with 4 USB 3.0 ports and 2 USB 2.0 ports, up to 4 cameras can be connected to it, which can acquire image data from the production line in real time, perform preliminary processing and analysis, and transmit the processed data to the AI system to realize intelligent identification and classification of product defects. In addition, its rich I/O interfaces can be connected to a variety of devices such as load cells, code scanners and automatic printers.

In addition to the powerful visual computing capability, the fan design of VMC-1000 meets the dustproof requirement of the production line, which can effectively improve the quality and stability of parts production, reduce the rate of defective products, and enhance the competitiveness of enterprises. More importantly, VMC-1000 industrial computer can be plugged into a POE network card, one cable to transmit data and power supply at the same time, which not only reduces the installation and maintenance costs of the equipment, but also improves work efficiency and flexibility.

With the continuous development of artificial intelligence technology, the application of industrial computer in AI defect detection system will also continue to innovate and improve. In the future, industrial computer will be more intelligent and flexible, and can adapt to the needs of different production scenarios. At the same time, it can also take advantage of big data and cloud computing and other technologies to achieve a deeper analysis and optimization of product quality. Therefore, the application of industrial computer in AI defect detection system will become an important means of industrial production quality control, providing a solid assurance for enterprises to realize sustainable development.

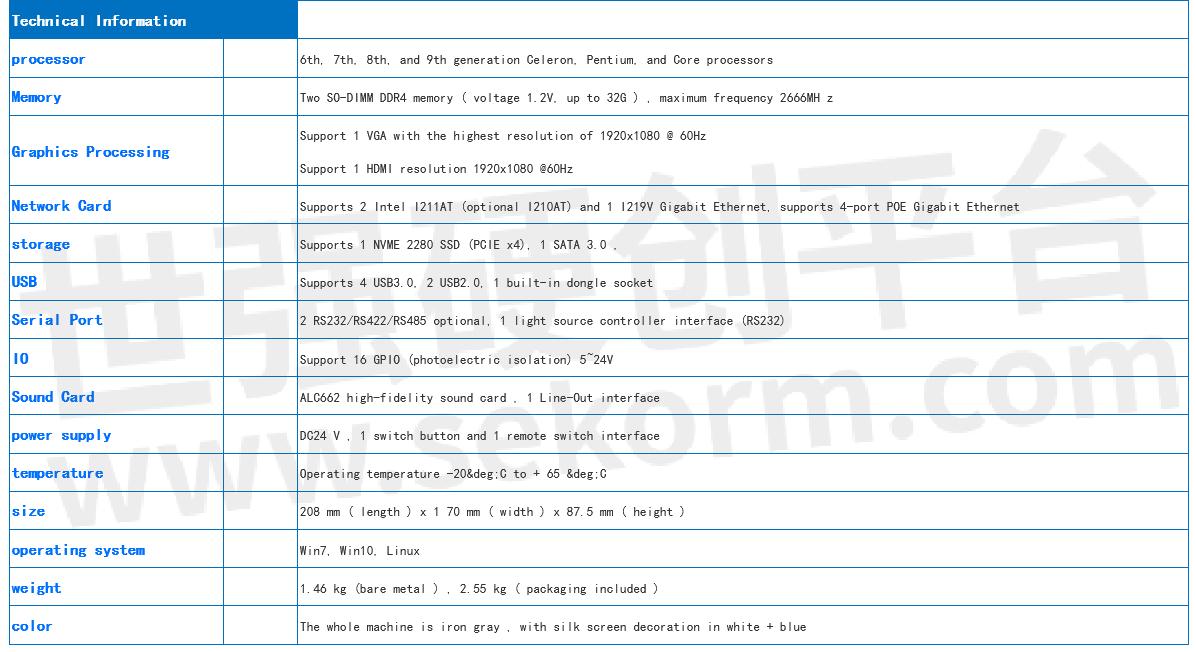

VMC-1000

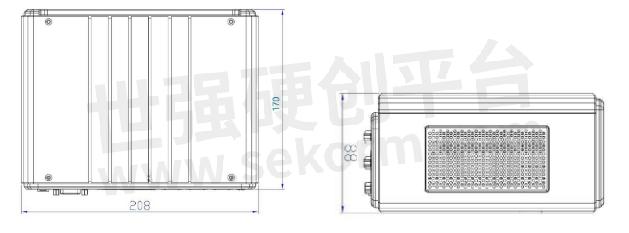

Dimensions

Appearance

- +1 Like

- Add to Favorites

Recommend

- YDSTECH IPC-8610 Industrial Computer for Rapid CT Inspection of Lithium Batteries

- How About An Integrated Industrial Computer and Its Benefits?

- Application of Customized Industrial Panel PC in the Industrial Field

- Application of Embedded Industrial Motherboards PCM-B252 in Petroleum Analyzing Instruments

- Application Cases of YDS ECS-E170 Industrial Computer in Fruit and Vegetable Quality Inspection Industry

- The Use of Fanless Industrial Computers ECS-ADP351 in Industrial Robots

- Where are the Specific Core Advantages of Industrial Tablet PCs?

- What Elements should be Paid Attention to in the Research and Development of Industrial Flat Panel?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.