Application Cases of YDS ECS-E170 Industrial Computer in Fruit and Vegetable Quality Inspection Industry

Ensuring product quality and customer satisfaction is a critical task in modern industrial production, especially for perishable products such as fruits and vegetables, where the accuracy and efficiency of quality inspection is crucial. The traditional quality inspection process for fruits and vegetables relies heavily on manual visual inspection involving factors such as weight, color, size and appearance. However, this approach is both time-consuming, labor-intensive and expensive. What's more, the inspector's subjective judgment may be inaccurate, leading to misjudgments. In response to these problems, modern technology offers new solutions.

Features and Advantages of ECS-E170 Industrial Computer System

1. Advanced Hardware Configuration: ECS-E170 is equipped with Intel® Atom® J6412 quad-core processor, which realizes high-performance visual computation and analysis. Meanwhile, with 4 USB 3.0 ports and 2 USB 2.0 ports, up to 4 cameras can be connected to realize multi-dimensional data acquisition and analysis.

2. High-precision quality grading: By analyzing the color, weight, shape, surface damage and other characteristics of fruits and vegetables in real time, the ECS-E170 system can achieve high-precision quality grading of fruits and vegetables. Meanwhile, damaged fruits will be marked and displayed for the attention of quality inspectors.

3. Abundant I/O interfaces: ECS-E170 system can also be connected to various devices, such as weighing sensors, code scanners and automatic printers, to enable the expansion and integration of device functions.

4. Fanless design: ECS-E170 adopts fanless design to meet the dustproof requirement of production line and ensure the stability and reliability of equipment operation.

The application of industrial AI technologies in the field of fruit and vegetable quality inspection has revolutionized the traditional quality inspection process. By improving inspection accuracy and efficiency and reducing labor and production costs, these technologies have brought huge economic benefits and competitive advantages to manufacturing enterprises. As technology continues to innovate and develop, industrial AI technology will definitely become an important tool for manufacturing enterprises in the future.

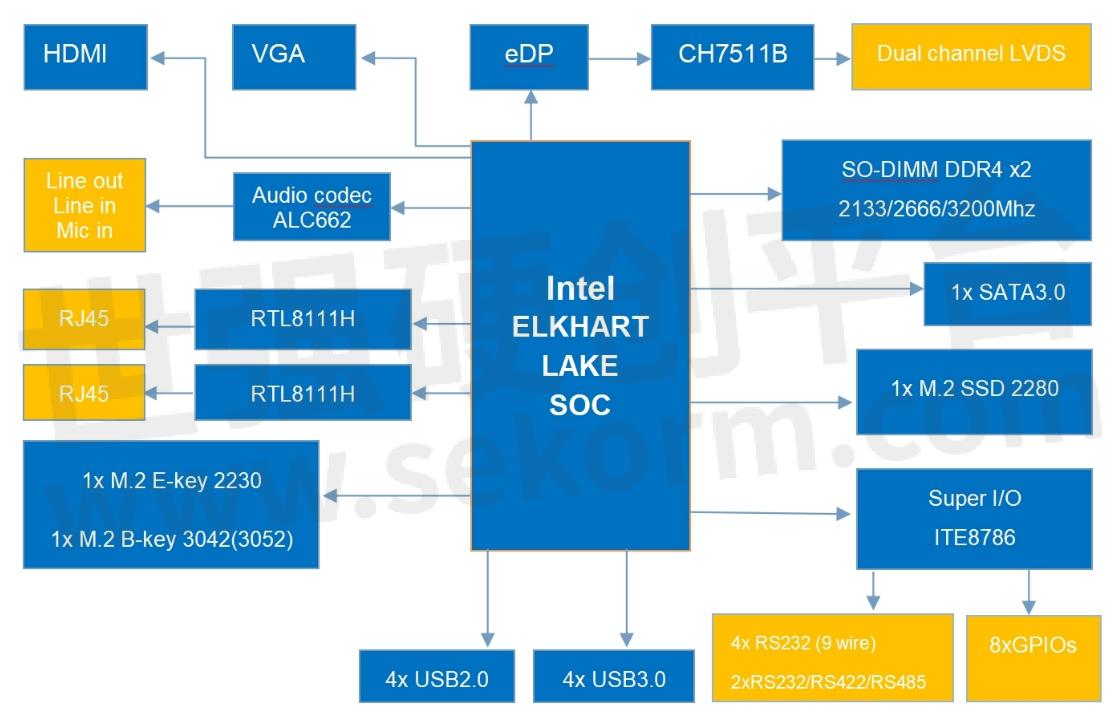

PCM-E170

Mini-ITX motherboard with Intel® Elkhart Lake ™ Series SOC

Elkhart Lake series SOC, power consumption: 6.5~12W

SO-DIMM x2 DDR4 memory (voltage 1.2V, support up to 32G ) maximum frequency 3200MH z

Intel 11th generation graphics core , supports DX12, MPEG2, H.264, JPEG/MJPEG, H.265 (HEVC)

Support eDP 1.3 , HDMI 1.4, VGA, LVDS ( 18/24- bit single or dual channel)

Support 10/100/1000Mbit Ethernet , SATA, NVME SSD

USB 2.0 and USB 3.0 interfaces , RS232/422/485 serial ports, GPIO interfaces

Voltage: + 12V ~+ 24V , + 12V is recommended

Operating temperature: -20℃ ~ + 60℃ (optional -40℃~ + 75℃)

PCM-E170 Block Diagram

- +1 Like

- Add to Favorites

Recommend

- YDSTECH IPC-8610 Industrial Computer for Rapid CT Inspection of Lithium Batteries

- How About An Integrated Industrial Computer and Its Benefits?

- Application of Customized Industrial Panel PC in the Industrial Field

- Application of Industrial Computers in Industrial AI Defect Detection Systems

- Application of Embedded Industrial Motherboards PCM-B252 in Petroleum Analyzing Instruments

- The Use of Fanless Industrial Computers ECS-ADP351 in Industrial Robots

- Where are the Specific Core Advantages of Industrial Tablet PCs?

- What Elements should be Paid Attention to in the Research and Development of Industrial Flat Panel?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.