The Engineer‘s Toolkit: 8 Best Tools for Effective Material Selection

Time is valuable when it comes to product design. Having the right tools to make informed decisions can be the key distinction between a successful project and one that doesn't meet expectations.

ROGERS Corporation has developed comprehensive web-based tools to simplify material selection. They aim to empower engineers and technical personnel with information to make design choices as easy as possible.

Let's review the top eight elastomeric material selection and design tools:

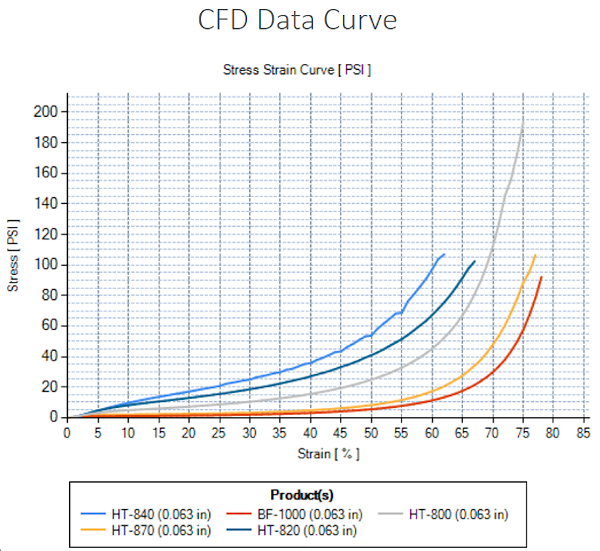

Compression Force Deflection Curve Tool: Leveraging stress-strain data, the Compression Force Deflection (CFD) Curve Tool aids engineers in identifying BISCO® silicones or PORON® polyurethane materials to achieve the appropriate sealing and pressure management performance. This web-based tool allows engineers to enter a specific thickness range, select products of interest, and compare the CFD curves of those products in an auto-generated graph. By visualizing compression characteristics through a full compression curve (see image below), engineers can make better decisions regarding material selection for applications requiring specific compression characteristics. As a bonus, users can export detailed data into industry-recognized engineering programs for further analysis.

Here is an example of what the generated CFD curve with several BISCO silicone materials looks like:

Application Design Tool: Determining the right material for a specific application is easier than ever with the Application Design Tool. This intuitive platform lets engineers input project requirements to quickly identify the most suitable BISCO silicone or PORON polyurethane material options. By streamlining the material choice process, this Tool saves valuable time and ensures that engineers make informed decisions.

Product Properties Guides: Rogers Corporation's Product Properties Guides serve as a comprehensive resource for engineers seeking technical product information on BISCO, ARLON®, DeWAL®, and PORON materials:

BISCO Silicones Product Properties Guide

ARLON Silicones Product Properties Guide

DeWAL Film and Tape Product Properties Guide

PORON Polyurethanes Product Properties Guide

By filtering product information with various criteria, such as property groups, product categories, or units, engineers can efficiently narrow their search to find the optimal material for their application. Additionally, engineers can quickly access a specific material's technical data.

Gap Filling Tool: The Rogers Gap Filling Tool allows engineers to assess material suitability for gap filling and sealing applications by evaluating user-supplied working gap and tolerance, adhesive thickness (if applicable), and gasket area. The tool then automatically suggests the appropriate PORON polyurethane or BISCO silicone materials based on compression characteristics and resulting compression force for that application.

Impact Prediction Tool: By utilizing impact data, engineers can identify the best BISCO silicone or PORON polyurethane material to mitigate impact forces effectively, enhancing product safety and durability. (Note: The Impact Prediction Tool requires creating a user account to gain access).

PORON Battery Pad Application Product Selector Tool: Designed specifically for electric vehicle (EV) and hybrid electric vehicle (HEV) battery pad applications, this Tool assists engineers in determining the best PORON polyurethane material. By considering factors such as mechanical properties and thermal conductivity, engineers can optimize battery pad design for improved performance and reliability.

Vibration Isolation Tool: The Vibration Isolation Tool recommends the appropriate BISCO silicone and PORON polyurethane materials for vibration mitigation applications.

BISCO® MF1® Rail Seat Cushion Total Cost of Ownership: This Tool aids in calculating the total cost of ownership for BISCO MF-1 rail seat cushions. By considering factors like material cost and maintenance requirements, engineers can make informed decisions regarding cushioning solutions for rail seat applications, optimizing cost-effectiveness and performance.

Key Points

Having access to a robust tool kit can simplify complex design decisions.

Rogers Corporation offers a variety of design tools - based on real test data - to help engineers confidently select the right material.

Speak with a Rogers Sales Engineer to receive more guidance on material selection.

- +1 Like

- Add to Favorites

Recommend

- Rogers Announces Acquisition of Silicone Engineering

- Sekorm Became an Authorized Distributor of Rogers

- Rogers Announces Termination of Merger Agreement with DuPont

- Rogers Elastomeric Material Solutions Protects Athletes Step by Step During the Paris Olympics

- Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

- Rogers Corporation Announces Intention to Consolidate Manufacturing Facilities for RO3000® and RO4000® Product Lines

- Rogers Corporation Introduces New Water-Resistant Flexible Heater Substrate

- Rogers Expands Capabilities and Services with New Application Laboratory

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.