Driving the Future -Rosenberger Connector Systems for E-Mobility

The transition from combustion engines to electric vehicles makes road transportation more climate-friendly and sustainable. This shift demands continuous innovations in connector technology. Electrical components must be robust, space-saving and lightweight as possible, and capable of safe operation at high voltages and extreme currents. ROSENBERGER's primary goal is to deliver the lowest possible contact resistances with optimized EMI performance characteristics while maintaining reliable quality standards. Rosenberger HV range includes highly compact connection solutions operating at up to 1000 V with continuous currents ranging up to 450A.

Rosenberger works closely with automotive manufacturers, TIER1 suppliers, and harness makers to develop tailored or custom solutions and facilitate the integration of their products into various vehicle models. This collaboration helps in understanding the manufacturers' requirements and delivering solutions that meet those needs.

Standard Portfolio

Rosenberger extensive portfolio of high-voltage connectors has been developed especially for optimized power transmission in electric vehicles. For Rosenberger, the product development goal is clear: minimum contact resistance plus high power density coupled with excellent EMC performance properties. They meet customer requirements in terms of quality, reliability, performance and price.

The shielded HVR® product series includes extremely compact connection solutions up to 1000 V DC with continuous currents up to 450 A that can be operated over entire product lifetimes.

Additional Rosenberger develops and offers several unshielded HVU® series, such as HVU®48, HVU®50 and HVU®400. These cost-effective connectors are tailored to the use case, focussing on transmitting power while maintaining high voltage safety. Current capacity ranges from 60A, 87.5A up to 340A at a working voltage of 1000V DC.

Features and Benefits

High current performance

Minimum installation space

Highest vibration classes

Best EMI performance

Qualified to national and international standards (LV215, USCAR)

HV Applications

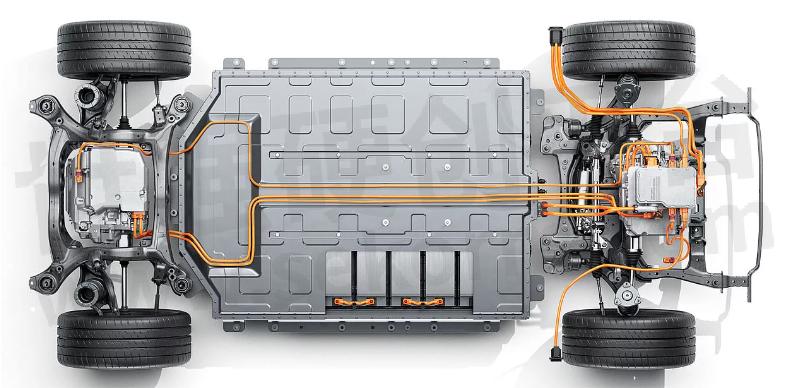

High voltage applications play a crucial role in the functioning and performance of electric vehicles (EVs). EVs rely on high-voltage systems to power various components, improve efficiency, and maximize driving range.

Key areas where high voltage is utilized in an electric vehicle include

Battery system

Electric motor

Power electronics

Charging infrastructure

Regenerative braking

Auxiliary systems

E-Mobility

- +1 Like

- Add to Favorites

Recommend

- RJ45 Connector for PoE+ Cabling Solution Can Provide up to 90W of Power Supply | Rosenberger

- Rosenberger Received The TOP 10 Brand of China and The Most Influential Brand in 2020 Wiring Net‘s IT Media Matrix Annual Selection

- Rosenberger Provides A Whole Cable Solution for Changchun Longjia International Airport

- Rosenberger Expands High-Speed Manufacturing Capabilities in USA

- Rosenberger OSI introduces the new PreCONNECT® SEDECIM cabling system

- Rosenberger Supporting The Financial Technology Work of the People‘s Bank of China

- Certified for Aerospace Applications, Rosenberger Connectors SMP, SMA and RPC-2.92 Series on the Way into Space

- Rosenberger Signs an Authorized Distributor Agreement with Sekorm

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.