Infineon Continues to Partner with Boyd to Develop Improved Systems and Solutions for Cooling Electronics in HEV/EV

Infineon Technologies continues to partner with BOYD to develop improved systems and solutions for cooling electronics in hybrid and electric vehicles (HEV/EV). We see that EV and HEV production and consumer adoption is exponentially growing and will continue to as environmental standards push for cleaner, more compact, and less expensive transportation.

Customer demands require greater connectivity and more powerful internal electronics and vehicle operating systems in addition to already increased power requirements. New technologies and improved electronics ultimately result in additional waste heat. Without adequate thermal management, electronic reliability and lifetime required for vehicles running safely is significantly impaired to the point of device and system failure. Solutions like liquid cold plates and heat sinks safely remove heat from these crucial electronics to ensure reliable performance.

The Infineon/Boyd partnership enables our team to jointly design and produce fully optimized, highly effective cooling solutions for Infineon’s high-performance electronics for electric vehicles and hybrids.

Thermal Characterization of Infineon’s Double Side Cooled (DSC) MOSFETs and Boyd’s Dual Sided Liquid Cold Plates

The latest efforts of the Infineon/Boyd partnership produced a paper detailing the manufacturing of Boyd’s dual sided liquid cold plates, its thermal and hydraulic characteristics, and its impact on Infineon’s DSC Module. Engineers at both Infineon and Boyd collaborated in explaining the manufacturing process of the liquid cold plates, modeling and testing the DSC modules with a lab cooler and with Boyd’s DSC liquid cold plates, and comparison of a Si-IGBT DSC versus a SiC-MOSFET DSC module.

The Introduction of the HybridPACK™ and HybridKIT™

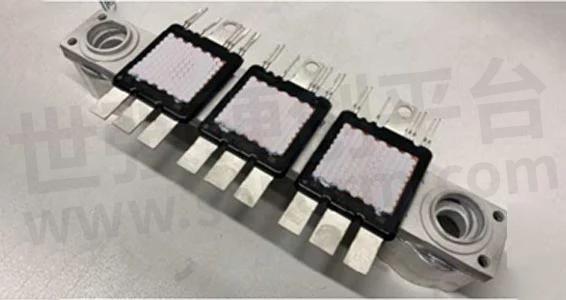

Boyd previously collaborated with Infineon to develop liquid cold plates for Infineon’s Double Side Cooled MOSFETS, the HybridPACK™ specifically designed for electric vehicles. Additionally, Boyd helped introduce the HybridKIT™, an all in one test kit ideal for research & development and initial prototyping. Due to excessive heat loads, sufficient cooling is necessary even for initial testing. Boyd’s specialty liquid cold plates dissipate large amounts of heat in a compact, lightweight form factor and offer greater design flexibility for developing prototype systems.

The HybridKIT™ includes electric drive modules, evaluation boards and drivers, and Boyd’s DSC liquid cold plate, which was designed specifically for this kit to represent production manufacturing performance and envelope.

- +1 Like

- Add to Favorites

Recommend

- Advantages of Vacuum-brazed Cold Plates

- The BOYD Specialty Vehicle Battery Liquid Cold Plate Increases Thermal Performance While Decreasing the Weight of the Battery Pack by over 40%

- Aavid‘s Liquid Cooling Systems: Modular or fully customized liquid cooling optimized for improved heat dissipation in condensed volumes

- How to Distinguish the Advantages and Disadvantages of Water Cold Plates?

- Nextron Ultra-low Profile Water Cooling Cold Plate Solves Heat Dissipation Problems

- Boyd Corporation Acquires Lytron, Expands Liquid Cooling Offerings

- Risks of Channel Contamination and Cleaning Control Techniques in the Manufacturing Process of Liquid-Cooled Plates

- What Issues Should You Pay Attention to When Choosing A Cold Plate Manufacturer?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.