Digital Isolator Devices That Can Protect 24 V Digital Inputs & Outputs in Industrial Environments

Industrial environments demand a lot from control systems. Devices such as programmable logic controllers (PLCs) must operate continuously with various components and as little maintenance and downtime as possible. However, a PLC is only as good as the input /output capabilities of the digital channels connected to the industrial ecosystem. Harsh, noisy environments and various unknown factors can all contribute to design challenges that affect digital channel reliability, resulting in possible circuit damage, downtime, and system failure. In the dual webinar sessions, Protecting 24 V Digital Outputs from the Unknown and Factories are Dirty – Protecting Industrial Digital Inputs, senior product manager Asa Kirby and applications engineers Travis Lenz and Kevin Huang describe the design challenges specific to industrial digital channels and how to mitigate them using Silicon Labs' Si834x and Si838x Digital Isolator devices.

Environmental Challenges

Figure 1. The Harsh Industrial Environment

Industrial ecosystems present a multitude of conditions that can result in damage to digital input and output channels. The most common challenges include:

· Limited design space. Devices are often inside small cabinets shared with other components.

· Interoperability with components from multiple vendors due to longevity of systems.

· Unknown sensors, actuators, and cables

· Wide range of power sources with varying quality. For example, undersized power sources or defective or failing power sources can cause brownout conditions.

· Multiple noise types due to high voltage sources, shared cable trays, and long cable runs with poor shielding and grounding.

· Wide range of temperature and humidity conditions due to devices operating outdoors in extreme temperatures.

· 24/7/365 operation. Controllers are expected to automate tasks with little interaction.

· Lifetimes measured in decades. Over time, multiple generations of components are added and serviced by various technicians.

Input/output-specific challenges include managing overload conditions and driving inductive loads for outputs and device compatibility and assembly/installation protection for inputs. Industrial systems must be able to handle all these varied design challenges while operating in harsh environments.

Silicon Labs' Digital Isolator Solutions

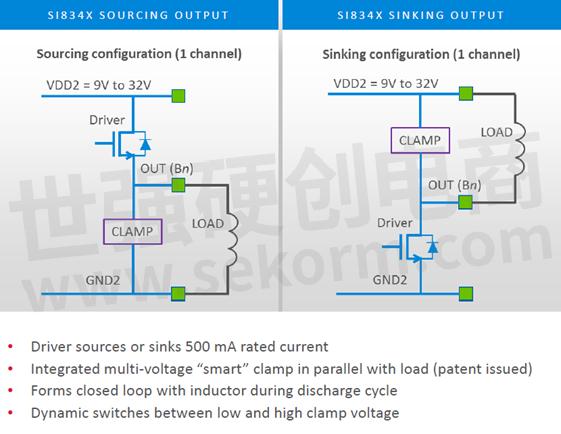

Silicon Labs' digital isolators provide optimal solutions to the unique challenges of industrial environments. Our Si834x isolated smart switches are ideal for driving resistive and inductive loads, including solenoids, relays, and lamps commonly found in industrial control systems. They are fully compliant with IEC61131-2, so they interoperate well with other channels. Each switch can detect an open circuit condition and is protected against over-current, over-voltage from demagnetization (inductive kick or flyback voltage), and over-temperature conditions. An innovative multi-voltage smart clamp can manage an unlimited amount of demagnetization energy (EAS). Si834x switches are available in Parallel or SPI input types and sourcing or sinking output types. With substantial power savings and a compact 9x9 DFN package, these switches reduce board space and design headache!

Figure 2. Si834x Smart Clamp

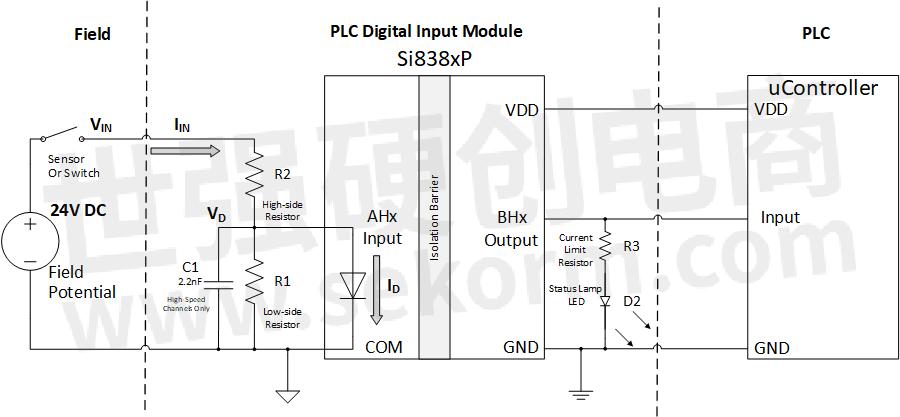

Our Si838x isolated multi-channel input isolators are high-density, highly flexible devices that are ideal replacements for traditional optocouplers. They offer eight channels of 24 V digital field interface in a single compact QSOP package with integrated safety rated isolation. With a few external components, this structure provides compliance to IEC 61131-2 switch types 1, 2, or 3. The input interface is built on our ground-breaking CMOS-based LED emulator technology, which means the devices can handle sourcing or sinking configurations without a power supply on the field side. By utilizing our proprietary silicon isolation technology, these devices support up to 2.5 kV RMS withstand voltage, enabling high-speed capability, high noise immunity of 25 kV/µs, reduced variation with temperature and age, and better part-to-part matching. One Si838x isolator can replace eight traditional optocouplers, making them ideal solutions for space-constrained industrial facilities.

Figure 3: Si838x Legacy Optocoupler Replacement

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.