Epson, JR East, and Nagano Keiki Jointly Develop a Practicable Deflection Monitoring Device for Railway Operators

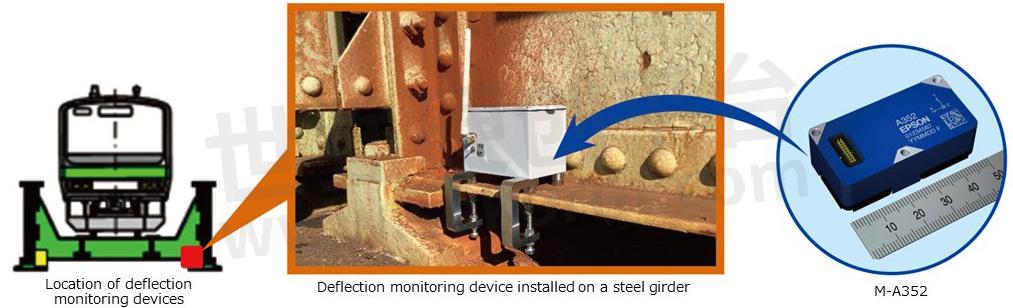

Seiko EPSON Corporation (TSE: 6724, "Epson") announces the successful development of a practicable deflection monitoring device equipped with Epson's high-performance M-A352 three-axis accelerometer. Jointly developed with East Japan Railway Company ("JR East") and Nagano Keiki Co., Ltd., the device remotely monitors the condition of steel railway bridge girders.

In recent years, railway operators have been facing challenges in the maintenance of steel railway bridge girders, both in terms of manpower and measurement accuracy. This has led to a growing demand for monitoring solutions that use high-precision accelerometers to automatically measure the magnitude of the vertical movements, or deflections, of girders when trains pass over them.

This jointly developed monitoring device uses Epson's M-A352 sensor to automatically measure these deflections. Signal processing converts the measurement results into easily manageable data that is then sent to the operator by e-mail. The device makes it possible to take measurements remotely, thus helping to automate monitoring work that has traditionally relied on workers in the field.

Epson's accelerometers, first launched in 2014, have been used in an array of applications, earning an excellent reputation for outstanding performance and quality.

The M-A352 is an accelerometer that uses Epson's own quartz crystal technology to clearly identify dominant frequency and capture even accelerations of very small magnitude-something that ordinary acceleration sensors cannot reliably do. This enables highly accurate measurement of vibration, regardless of the magnitude of deflection, and contributed significantly to the construction of an accelerometer-based deflection detection algorithm by JR East. The high durability and good temperature stability of the M-A352 was key to the development of a practicable monitoring device since these devices are installed outdoors and need to last for a long period of time.

Epson will help to make communities safer by refining its efficient, compact, and precise technologies to enable extraordinarily precise and accurate sensing in a wide range of applications, including seismic and environmental vibration measurements, health monitoring of large structures, and bridge monitoring.

Epson Sensing Systems

Epson's sensing solutions are built around high-performance quartz crystal sensor elements that are produced from Epson's own high-quality synthetic crystals in a proprietary microfabrication process. Epson accelerometers equipped with these high-performance quartz crystal sensor elements feature low noise, high resolution, wide dynamic range, and high stability.

- +1 Like

- Add to Favorites

Recommend

- Seismic Intensity Meters Equipped with Epson‘s M-A352 Accelerometer Certified by the Japan Meteorological Agency

- News | Epson Launches 4th-Generation Optical Engine for Smart Glasses

- Epson‘s High-performance Cushioning Material Wins the WorldStar Global Packaging Awards 2024 in the Electronics Category

- Epson Develops an New Industrial 3D Printer that Can Use Commonly Available Materials

- High-stability GYRO Sensor by Epson with Bias Output Stability and Low Noise

- Epson Becomes the Manufacturing Industry‘s First to Switch to 100% Renewable Electricity at All Sites in Japan

- Epson to Start Selling New Sensing Technologies and Launch New Sensing Analysis Technology Business

- Epson Shipping Samples Of Low-Power 16-Bit Microcontrollers Equipped with High-Precision A/D Converter

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.