3D Vapor Chambers: Revolutionary Heat Dissipation

As the field of AI continues to evolve, there is a growing need for more minor and more powerful semiconductor chips. However, upgrading semiconductor technology while keeping costs low has increased power consumption and heat generation in these chips. This has caused TDP rates to accelerate, making it increasingly challenging to manage heat in high-performance, compact electronics.

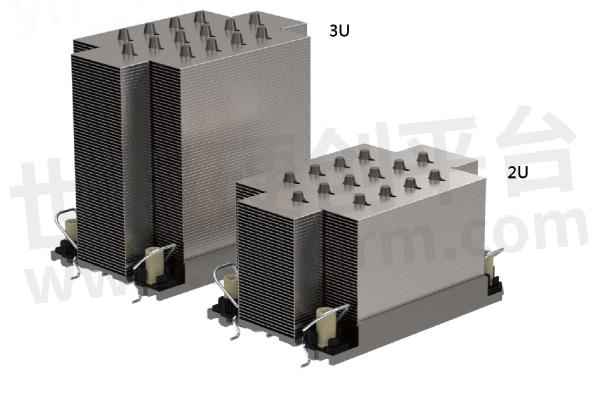

To address this issue, a 3D Vapor Chamber has been developed, which can handle over 500 watts of power. This technology is ideal for servers, base stations, repeater stations, and data centers. As a result, the global data center liquid cooling market is expected to grow from $1.82 billion in 2021 to $7.12 billion by 2028 at a compound annual rate of 21.5%.

Optimal Cooling Strategies and Cost Efficiency

Air cooling is typically enough for devices with a Thermal Design Power (TDP) of up to 350 watts, while liquid cooling is recommended for TDPs ranging from 350W to 1000W. For TDPs beyond 1000W, immersion liquid cooling is necessary.

However, recent corporate reports suggest that air cooling can effectively handle up to 1000W of heat energy. The optimal threshold for air cooling efficiency, though, lies around 500W. These evolving data on the scope of air cooling indicate ongoing technological advancements that meet customer demands.

The cost of 3D vapor chambers is approximately twice as high compared to traditional heat pipes or plates. This presents a favorable cost advantage over liquid cooling solutions, which can cost several times more than 3D VC. Therefore, 3D Vapor Chambers are an attractive choice in thermal management solutions.

3D Vapor Chambers: Efficient Thermal Management

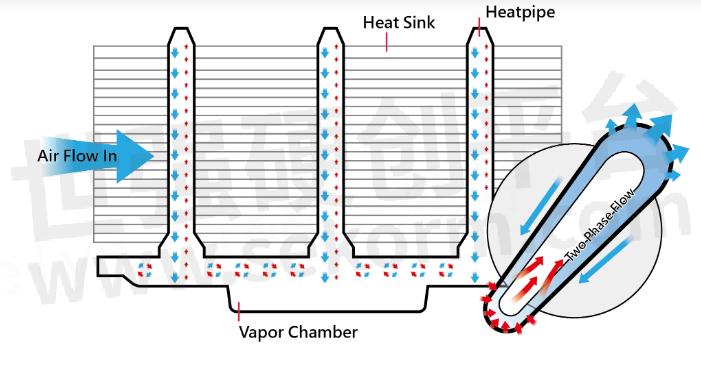

The 3D Vapor Chamber is a highly efficient thermal management solution for electronic devices. Unlike traditional heat plates that rely on heat pipes or plates, this chamber leverages the phase change properties of fluids to dissipate heat through a sealed chamber, surpassing the efficacy of conventional methods. The chamber's flexibility enables customization to cater to diverse client requirements. It offers a cleaner and more space-efficient solution, ensuring optimal thermal management.

Although the initial investment in a 3D Vapor Chamber may be higher than traditional heat dissipation methods, its superior thermal performance justifies the cost. This chamber outperforms conventional solutions, particularly in the medium to high power range, providing a cost-effective alternative to liquid cooling systems. Its adept heat dissipation capabilities ensure prolonged device functionality, making it a cost-efficient choice in the long run.

Enhancing Performance with Versatile Applications

The 3D Vapor Chamber technology is helpful in high-end server networks such as base stations, repeater stations, and data centers. This technology disperses heat efficiently in compact and slim device designs, improving reliability and minimizing maintenance. This technology is versatile and can integrate into various electronic systems, enhancing their performance and longevity.

The 3D Vapor Chamber technology is a suitable solution for the cooling challenges that modern electronic systems face, especially those with high-performance standards and compact designs. Integrating this technology into network infrastructures like base stations and repeater stations can improve their performance and longevity. Similarly, incorporating this technology into high-end servers and data centers can increase cooling efficiency, reduce maintenance costs, and enhance reliability.

Nextron's Role in Advancing 3DVC Technology

Nextron stands at the forefront of innovation, seamlessly integrating 3DVC technology into high-speed transmission systems. Nextron's expertise lies in crafting tailored solutions that meet specific application demands, ensuring optimal thermal management and performance. With advanced manufacturing techniques and a commitment to excellence, Nextron is poised to drive the future of thermal management solutions, unlocking limitless possibilities in the realm of electronics.

- +1 Like

- Add to Favorites

Recommend

- Delta’s High-efficiency Heat Transfer Solutions--Slim Heat Pipes and Slim Vapor Chambers

- Heat Pipes Versus Vapor Chambers: What‘s the Difference?

- Titanium Vapor Chamber Enables Most Powerful GPU for Mobile Computing Devices | Boyd

- SanDeYing Electronic PCB 3D Models Provides A Clear View of All The Parts on PCB Boards in 3 Dimensions Length, Width, and Height

- ROHM Offers the Industry’s Largest* Library of LTspice® Models at Over 3,500 by Adding SiC and IGBTs

- 3D Mapping Drone Helps Create The Popular Game Black Myth: Wukong

- Energy Consumption in Data Centers: Air Versus Liquid Cooling

- Nextron Nominated as Mechanical Design Best Practice in Ansys 2020 Innovation Conference

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.