Basic Rules for Naming Industrial Connector Products

industrial connectors may be small in size, but the technology they embody is far from simple. On one hand, the reliability of electrical connections directly determines the performance of equipment systems. On the other hand, the classification of industrial connectors is extremely complex, given the various types of application scenarios. This actually presents a challenge for our everyday product development and system integration.

Below, starting with the definition and classification of connectors, GREENCONN will briefly introduce the basic rules for naming industrial connector products.

Definition of Industrial Connectors

Any electrical system must transmit electric current as a carrier of signal or energy, from one conductor through the contact between conductors to another conductor. This contact between conductors is called electrical contact, and the connector is what accomplishes this task, covering the "power," "signal," and "data" "lifelines". Figuratively speaking, industrial connectors are the "bridges" responsible for electrical or signal connections. Although they are only components, they are crucial.

There is still no unified classification standard for connectors, and as new application fields emerge, the structure becomes increasingly diverse, making it difficult to classify and name in a fixed pattern. Nevertheless, some basic principles of classification still remain valid for industrial connectors.

Prerequisites for the Classification of Industrial Connectors

According to the interconnection hierarchy of electronic equipment, it is divided into six layers:

First layer: interconnection of components to packaging;

Second layer: packaging interconnection to circuit boards;

Third layer: board-to-board interconnection;

Fourth layer: component to component interconnection;

Fifth layer: component to input/output interface interconnection;

Sixth layer: system to system interconnection.

Classified according to structure:

Classified according to power:

Power connectors (transmit power);

Signal connectors (transmit signals);

High-frequency connectors (transmit data).

Classified according to shape:

Circular connectors, commonly used in military equipment;

Rectangular connectors, widely used and rapidly developing.

Modular connectors, which have become the shining "star" in the connector family.

Therefore, in consideration of the technological development and industry application of industrial connectors, we can refer to the relevant technical standards when naming industrial connector products.

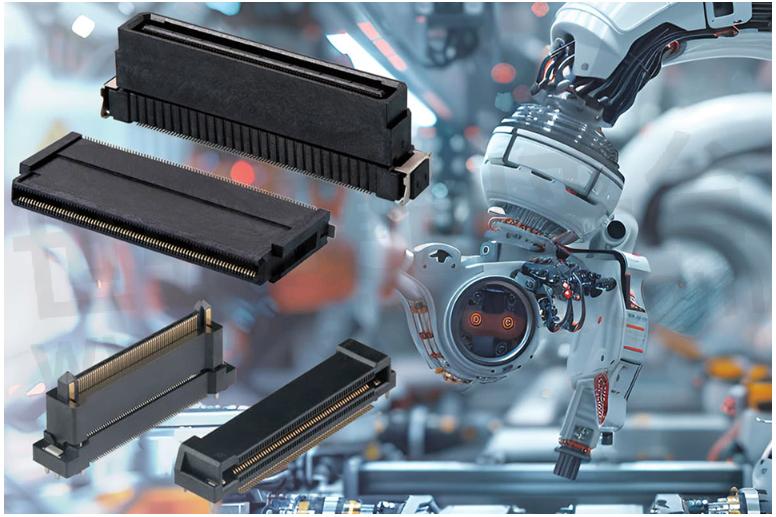

In the field of industrial connector products, Greenconn has been dedicated to developing advanced, durable, and high-quality industrial connector products for its customers, with competitive prices, high-level reliability and environmental friendliness. Greenconn is always ready to support the research and development of our customers' next-generation products.

- +1 Like

- Add to Favorites

Recommend

- Connection Form of Industrial Connector

- Three Development Trends of Industrial Connector

- Smart Industrial Connectors Face Opportunities and Challenges

- Greenconn‘s Industrial Connectors Boost the Upgrading of Industrial Robots and Industrial Automation

- Matters Needing Attention When Selecting Various Industrial Connectors

- With the Development of Electric Vehicles, the Industrial Connector Industry Has Also Ushered in Opportunities

- Greenconn Industrial Connectors Efficiently Empower the Industrial Internet

- Power Glory Supports Industrial Instrumentation Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.