Huaxuan Yang Electronics Introduced the Performance and Application Scenarios of 30 Silicon Carbide Schottky Diodes Models

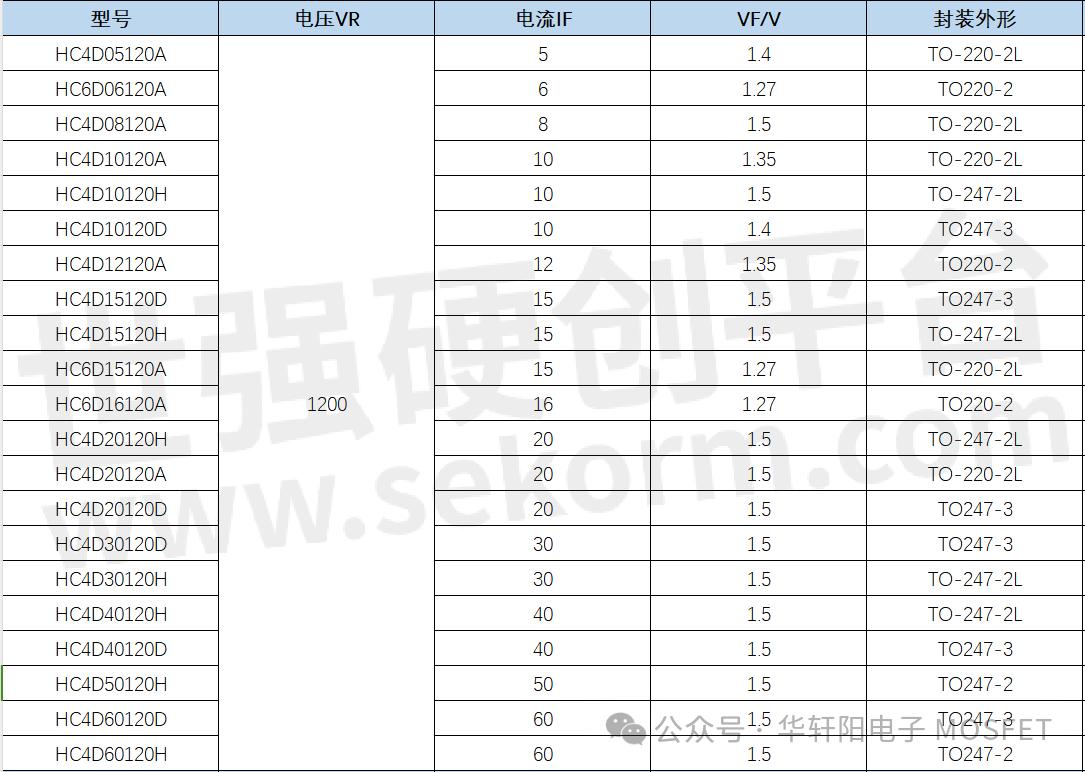

With the continuous iteration of technology and changes in market demand, Huaxuan Yang Electronics has been committed to the research and innovation of silicon carbide power devices. Today, we introduce our carefully crafted 30 silicon carbide Schottky series products. This series of products covers multiple key parameter configurations to meet the needs of different customers for high-performance power devices.

Among them, the reverse breakdown voltage (VR) is 650V, 1200V, and 1700V, which can adapt to various application scenarios from medium to low voltage to high voltage environments. The forward current (IF) range covers a wide range of 6A to 60A, providing flexible choices for different load requirements. In terms of packaging form, the industry standard and widely used TO247-2L and TO220-2L packaging types are mainly used. They not only have good heat dissipation performance but also facilitate convenient replacement in existing systems.

650V product and application instructions:

1. Data center power supply system: In server power, distributed power architecture (DPS), or uninterruptible power supply (UPS) systems within the data center, 650V silicon carbide Schottky diodes can be a key component of PFC (Power Factor Correction) circuits. Due to their zero reverse recovery current and low forward conduction voltage drop characteristics, they significantly improve the efficiency of the entire power system, reduce heating, and enhance system reliability.

2. Industrial motor drive: In the field of industrial automation and motor drive, 650V silicon carbide Schottky diodes can be used to build efficient and compact frequency converters and inverter drives, especially suitable for medium and low voltage motor drive systems, to improve the efficiency of electric energy utilization during motor startup and operation.

3. Household appliances and consumer electronics: In the power control modules of white goods such as household air conditioners, refrigerators, washing machines, and LED lighting driving power supplies, 650V silicon carbide Schottky diodes can achieve high efficiency and small volume power conversion, which is conducive to the miniaturization and energy-saving design of products.

1200V and 1700V are suitable for higher voltage level power electronic systems, such as:

1200V product and application instructions:

In the DC-AC conversion process of solar inverters, the 1200V voltage resistant silicon carbide Schottky diode can withstand the higher voltage generated by the photovoltaic array. At the same time, due to its lower switching loss and reverse recovery loss, the efficiency of the inverter is improved; In addition, in mid to high voltage level car chargers and DC/DC converters, 1200V devices are used to handle higher voltage platforms of battery packs, ensuring low loss and high efficiency even in high voltage operating conditions, which helps to enhance the endurance and charging efficiency of electric vehicles.

1700V product and application instructions:

In the power conversion module of industrial frequency converters, medium and high voltage motor drives, and energy storage systems, 1700V withstand voltage can safely withstand high voltage fluctuations from the grid input, as well as generate higher voltage stress during the inverter and rectifier stages, thereby improving the safety margin and energy efficiency of system operation. In addition, in the main drive inverter of high-performance electric vehicles, 1700V devices can meet the high-voltage driving needs of the driving motor, especially in electric buses and heavy-duty electric vehicles on high-voltage platforms, effectively reducing volume and improving energy conversion efficiency, further reducing overall vehicle energy consumption.

In summary, silicon carbide Schottky is driving higher efficiency and lower energy consumption in the industrial and automotive fields with its excellent performance indicators and diverse application scenarios. Looking ahead to the future, we will continue to closely follow market demand, support the green and low-carbon development of the industrial and automotive sectors with a richer product matrix and better services, and jointly create a better future of energy conservation and efficiency.

- +1 Like

- Add to Favorites

Recommend

- Hua Xuan Yang Electronics: Domestic Power Device Solutions for PC Power Supplies

- HXY MOSFET Provides A Power Device Solution for LED Backlit LCD TVs

- HUA XUAN YANG ELECTRONIC Provides A Power Device Solution Tailored for In Car Wireless Mobile Phone Chargers

- Application of HXY MOSFET in Micro Photovoltaic Inverters

- HXY MOSFET Innovates One Stop Power Device Solution for Neck Massage Devices

- Application of MOSFET in Outdoor Power Supply

- 8 Common Kinds of Failure Causes and Solutions of MOSFETs

- Factors to Consider When Choosing a MOSFET

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.