Brief Analysis of Common Connectors Classification

Connectors, as one of the electronic components, are used to establish circuit connections between different devices. There are various types of connectors, each suitable for different scenarios. In 1989, with the support of the National Electronic Distributors Association (NEDA) in the United States, leading manufacturers in the connector industry developed a set of connector classification standards and terminology.

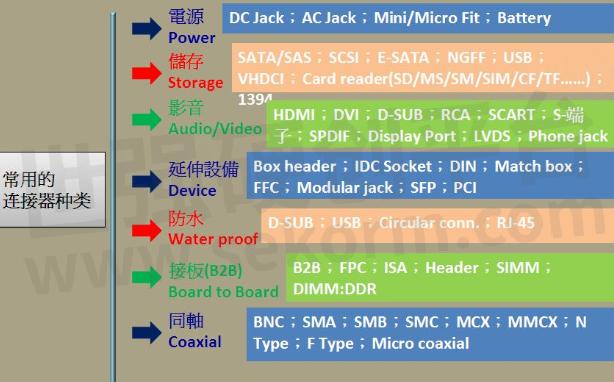

Connectors can be divided into five major categories: board-to-board connectors, high-frequency connectors, power connectors, modular connectors, and hot-swappable connectors.

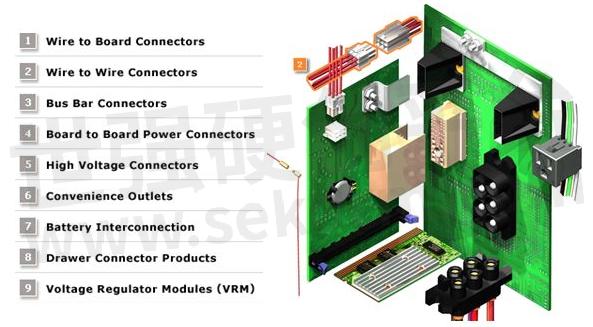

The First Category: Board-to-Board Connectors

A board-to-board connector is a type of connector used to connect the internal circuits on a circuit board to external circuits. Simply put, a board-to-board connector is a connector with one end fixed to the circuit board. Since the internal circuitry on circuit boards is often complex, using board-to-board connectors can greatly improve connection efficiency, reduce human errors and damage, and board-to-board connectors can be classified based on how they are fixed to the circuit board, including SMT surface mount connectors and DIP through-hole connectors. Both of these methods involve being fixed to the circuit board. Board-to-board connectors are widely used in electronic products such as computers, mobile phones, and various other electronic devices.

The Second Category: High-Frequency Connectors

High-frequency electronic connectors refer to all connecting components and accessories used in electronic signal and power applications. From the perspective of electronic packaging, connectors are components that interconnect parts that can be separated or replaced, in other words, they serve as bridges between signals. Therefore, the nature of high-frequency connectors influences the operational quality of electronic systems. Their main function is to transmit signals efficiently and completely. In the entire electronic system, high-frequency connectors are typical passive components, serving as connectors with good performance for high-frequency signal transmission. High-frequency connectors are commonly used in applications that require high-quality signal transmission in high-speed data and image transfer, such as television broadcasting, communication networks, etc.

High-frequency connector designs incorporate high-performance and highly reliable technologies to ensure high-quality connection performance. Connectors like SMA, N, BNC, among others, are widely used in RF transmission, electronic measurement, high-speed data transmission, and other fields.

The Third Category: Power Connectors

Power connectors are mainly used for circuit connections between cables, cables and equipment in electrical and electronic devices, especially in electrical control systems and power applications. Power connectors are typically used to transmit larger currents and voltages to electrical equipment, enabling the normal operation of the equipment. They facilitate the transmission of low-frequency signals, high-frequency signals, and electrical energy (power). Power connectors consist of fixed power connectors and free-end power connectors. Fixed power connectors are passive connection parts installed on panels and bases (or not installed), also known as sockets; free-end power connectors are active connection parts with connecting nuts or other locking devices, which match with fixed-end power connectors and are known as plugs. Power connectors enable circuit connection and disconnection through the engagement and separation of plugs and sockets. Power connectors are essential electronic components in various electrical and electronic systems and are widely used in industries such as aerospace, aviation, nuclear industry, weaponry, ships, electronics, transportation, computers, communications, medical, and oil exploration.

As the "neural hub and junction point" of electrical signal transmission systems, power connectors play a critical bridging role in signal transmission in circuits, and their quality directly impacts the performance and quality of products.

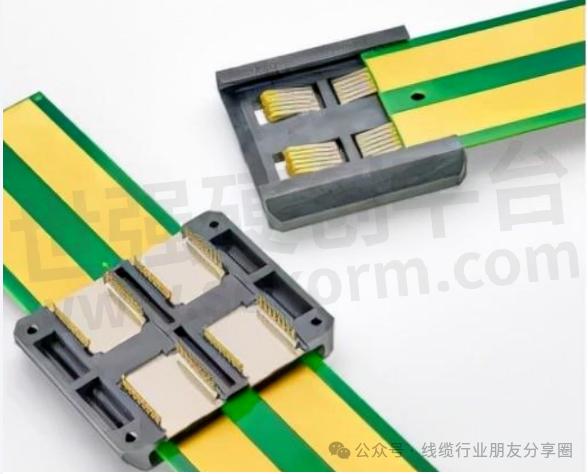

The Fourth Category: Modular Connectors

Modular connectors refer to connectors composed of multiple modules that can be interconnected as needed to achieve different functions. They are widely used in various applications such as network equipment, data acquisition devices, electronic testing, and computer work. Modular connectors employ fast transport technology, are easy to use, simple to maintain, have a long service life, and have a wide range of applications, making them an important connector in the field of electronic components.

Modular connectors are "self-constructing" interconnect products with selectable and configurable structural components to meet the physical or performance requirements of specific applications. Examples of modular products include generic housings that can accommodate various customer-selectable modules (power, signal, data, fluid, gas); common modules available in different housing or shell shapes (usually rectangular); or internal components assembled with specific pin numbers or types. These modular products can be assembled by connector suppliers or customers.

Modular products enable design engineers to create semi-custom connectors using multiple variables. This approach has many advantages compared to fully customized connector products. Modular connectors are typically lower in cost than custom products and can often reduce the number of individual connectors required. They are easy to upgrade and repair, allowing for the addition of functions or features, or the replacement of damaged parts with new components without replacing the entire connector. They reduce inventory by allowing multiple media to be used in one housing or shell instead of multiple connectors.

The Fifth Category: Hot-Swap Connectors

Hot swapping, also known as hot plugging, mainly occurs when modules, cards, components, or connections are inserted or removed from a system without shutting down the system's power. This is done to perform testing, troubleshooting, or signal adjustments without affecting the normal operation of the system, thereby improving system reliability, quick maintenance, redundancy, and timely disaster recovery capabilities. To ensure safe connection during hot plugging without damaging the equipment, connector manufacturers have designed some special hot-swap connectors, such as connectors with a make-first, break-last design, to ensure that the ground and system power connections are established before insertion or disconnection. Make-first, break-last connector products are designed with a make-first, break-last principle. These connectors use application-specific grounding designs, allowing the ground connection to be established before the power connection, and maintaining the connection until the power connection is broken.

In summary, hot-swap connectors are connectors with hot-swappable functionality used to protect equipment and components from the effects of accidental power loss or disconnection. Hot-swap connectors are widely used in various environments such as computer rooms, data centers, and network equipment, significantly improving equipment performance and service life, while also ensuring smooth data transmission and operation. Hot-swap connectors can automatically disconnect to prevent damage to affected circuit boards or equipment, greatly enhancing the overall performance of circuit boards and equipment.

In conclusion, connectors are a crucial part of electronic components, and it is essential for electronics professionals to understand various types of connectors. Different types of connectors, such as board-to-board connectors, high-frequency connectors, power connectors, modular connectors, and hot-swap connectors, each have their own characteristics and advantages tailored for specific scenarios. When selecting connectors, careful consideration is necessary to ensure improved connectivity efficiency, stability, and to guarantee the reliability of the entire circuit system.

Disclaimer: This article is excerpted from a network cable industry sharing circle. The views expressed in this article are solely those of the author and do not represent the views of Kinghelm or the industry as a whole. This article is shared for informational purposes only, to support the protection of intellectual property rights. When reposting, please indicate the original source and author. If there is any infringement, please contact us for removal.

- +1 Like

- Add to Favorites

Recommend

- The Difference between FFC Connectors and FPC Connectors

- Exploring the Benefits of Magnetic Ethernet Connectors in the Electrical Connector Industry

- What is the Role of Industrial Connectors? What Types of Industrial Connectors Can Be Divided into?

- DIN EN 1100 Certified WSMP® Coaxial Connectors, 45% Smaller than Standard SMP Connectors

- Advantages of Smiths Interconnect EMI Filter Connector and Filtered EMP Connectors

- Mission Critical: Maintain your RF cables and connectors 24 APR Mission Critical: Maintain your RF cables and connectors

- Terminal Connection Method of Electrical Connectors

- In-depth Understanding of the Connection Types of Industrial Connectors

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.