Terminal Connection Method of Electrical Connectors

Terminal connection refers to the way Electrical Connectors are connected to wires or cables. Choosing the terminal connection method properly and using the terminal connection technology correctly is an important aspect of using and selecting electrical connectors.

Welding of Electrical Connectors

Soldering is the most common method, and the most important thing for soldering connection is the continuity of metal between the solder material and the surface to be welded. Therefore, for the connector, solderability is important.

The most common coatings for electrical connector welding contacts are tin alloys, silver, and gold. The common solder ends of spring contact pairs are available with soldering types, eyelet soldering types, and notch soldering types. While the pinhole contacts have drilling arc notch types.

Crimping of Electrical Connectors

Crimping is a technique to compress and displace metals within the specified limits and connect the wire to the contact pair. A good crimping connection can produce metal intermolecular flow, which makes the wire and contact pair material symmetrical. This connection is similar to a cold welding connection, which can obtain better mechanical strength and electrical continuity, and can withstand harsher environmental conditions.

Currently, it is generally believed that a correct crimping connection is better than soldering, especially in high current occasions where crimping must be used. A dedicated crimping pliers or automatic/semi-automatic crimping machine must be used when crimping. The contact sleeve of the contact pair should be selected correctly according to the wire section. It should be noted that a crimping connection is a permanent connection and can only be used once.

Wrapping of Electrical Connectors

Wrapping is to directly wrap the wire around the angular contact piece winding post. When wrapping, the wire is wrapped, pressed, and fixed at the corner of the contact piece winding post under controlled tension to form an airtight contact.

There are several requirements for wrapped wires: the nominal value of the wire diameter should be within the range of 0.25mm~1.0mm; when the wire diameter is not greater than 0.5mm, the elongation of the conductor material is not less than 15%; when the wire diameter is greater than 0.5mm, the elongation of the conductor material is not less than 20%. The tools for wrapping include winding guns and fixed winding machines.

Piercing Connection of Electrical Connectors

Piercing connection, also known as insulation displacement connection, is a novel terminal connection technology invented by the United States in the 1960s. It has the characteristics of high reliability, low cost, and convenient use, and is now widely used in various printed board connectors.

It is suitable for connecting flat cables. When connecting, it is not necessary to strip the insulation layer of the cable. The tip of the "U"-shaped contact spring of the connector is inserted into the insulation layer, and the cable conductor slides into the groove of the contact spring and is clamped, thereby forming a tight electrical connection between the cable conductor and the connector spring. It only requires simple tools, but the cables with specified wire gauges must be used.

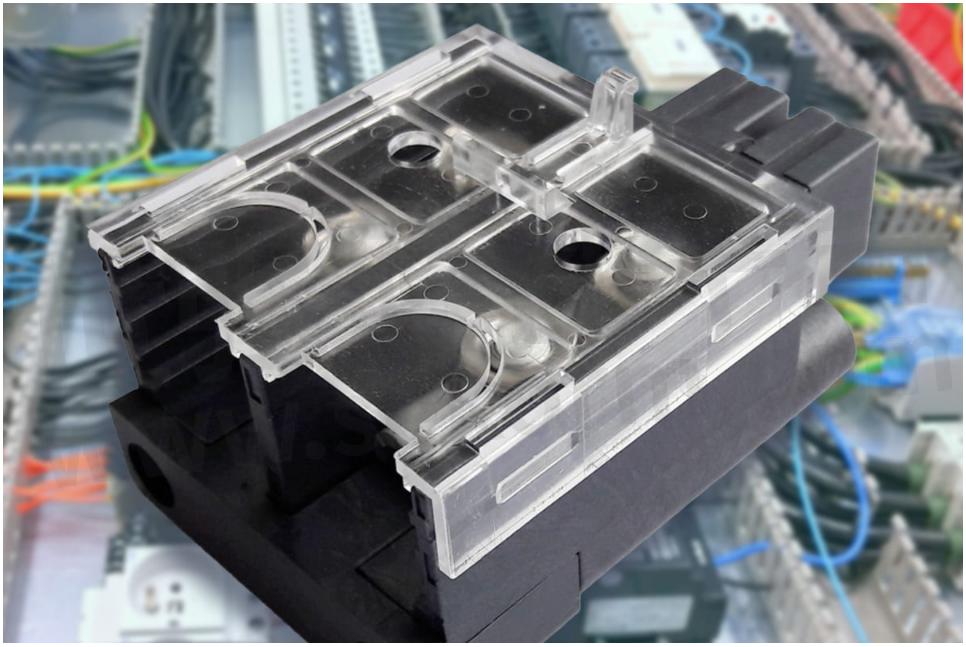

Screw Connection of Electrical Connectors

Screw connection is a connection method that uses screw-type wiring terminals. Attention should be paid to the maximum and minimum cross-sectional area of the allowed connecting wire and the maximum tightening torque allowed for different specifications of screws.

- +1 Like

- Add to Favorites

Recommend

- Selection Guide for Electrical Connectors

- Understanding Pin Headers for LED Lights in Electrical Connectors

- Kinghelm KH-A2508-04AB Screw Terminal: Revolutionizing Industrial Electrical Connections

- Kinghelm KH-XH-10A-Z Connector: Rated for 3A, Can Ensure Stable and Reliable Transmission of Electrical Signals

- GRL Supplied 40,000 Busbar System Adapters in 8,000 Cable Branch Boxes, Built a Better Electrical Control System for Farmland Irrigation

- GRL Offers the new HD11F-200A knife switch, Meet the Electrical Performance of the Distribution Boxes of China Southern Power Grid projects

- GRL Partnership with SEC in Electric Distribution Accessories

- Laird Thermal SystemsLaunches the OptoTEC™ MBX Series, a New Line of Micro Thermoelectric Coolers for High-performance Space-constrained Optoelectronic Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.