Haptic Technology 101: A Beginner’s Guide to the Different Types of Vibration Motors

Haptic feedback has become an integral part of our daily lives, often without us even realizing it. The term "haptic" comes from the Greek word "haptikos", which pertains to our sense of touch. Haptic technology uses our sense of touch to communicate by applying forces, vibrations, or motions, further enhancing the immersion into the digital world. Nowadays, the most common haptics use case is in smartphones—your phone vibrating whenever you get a call or text message—but it is also used in gaming, virtual reality, automotive, accessibility, and medical applications.

In order to create haptic effects, there's one crucial piece of technology needed: the haptic motor. Below, we've put together a beginner's guide to understanding the most popular types of haptic motors in the market.

1. Eccentric Rotating Mass (ERMs)

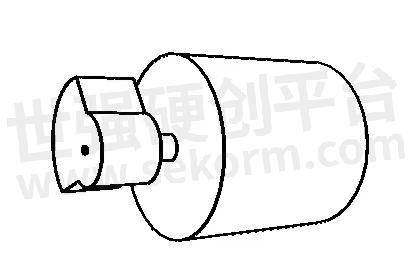

An Eccentric Rotating Mass (ERM) is a rotating electric motor with an off-center mass. As the ERM rotates, the mass becomes displaced, creating the 'rumble'or vibration feeling.

For many years, ERMs have been the most popular type of haptic motor due to their low cost, simplicity, and effectiveness. However, their vibrations lack precision and they can be slow to start and stop, limiting the range of sensations they can produce.

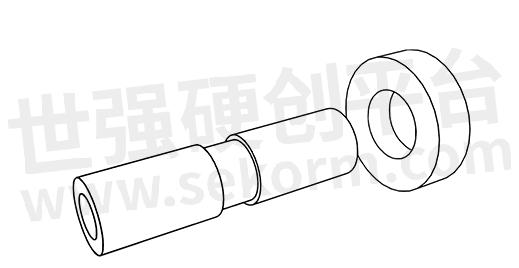

An ERM Motor

ERMs are most often found in gaming controllers and have recently been found in automotive use cases, due to their ability to produce strong and active vibrations. However, as of 2022, market analysts predict a slow shift towards LRAs within gaming, spearheaded by the launch of the PlayStation 5 DualSense controllers. Other industries, such as smartphones and wearables, are also shifting to LRA adoption.

2. Linear Resonant Actuator (LRA) Motors:

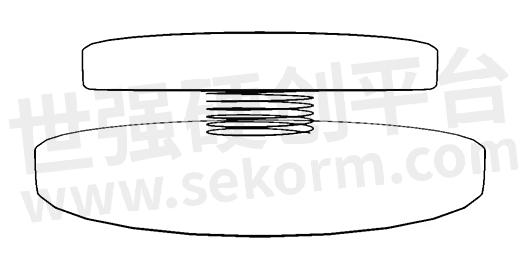

Linear Resonant Actuators (LRAs) are commonly found in wearables and smartphones. LRA Motors consist of a magnet attached to a spring, surrounded by an electromagnetic coil and housed in a casing. The coil is used to drive the motor by moving the mass back and forth within the housing, creating the vibrations we feel.

LRAs offer faster response times and more efficient power usage than ERMs, making them a popular choice for devices that require quick haptic feedback. However, they're more expensive than ERMs, and the spring is susceptible to wear and tear.

A type of LRA Motor

The most ubiquitous LRA motor is Apple's Taptic Engine, used in every Apple smartphone since the iPhone 6s. After its release in 2015, other smartphone companies followed this trend, adding using LRAs for their high-end and mid-end models. Most smartphones now use LRAs rather than ERMs for their haptic effects.

A type of LRA Motor

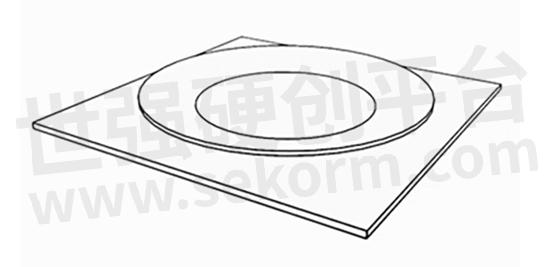

Piezoelectric actuators work by applying a voltage to piezoelectric material, which causes it to change shape and produce vibration. These actuators can produce highly detailed haptic feedback, making them ideal for applications where precision is key, such as in advanced medical devices. However, they’re considered to be rather fragile and are susceptible to breaking.

A Piezoelectric Actuator

Despite their small market share in the actuator industry, piezoelectric actuators are still widely used today. They can be found in laptop trackpads, satellites, and small medical devices. Piezoelectric actuators also have a good opportunity to grow in emerging markets such as AR/VR and wearable technology, where ERMs have been deemed to be a poor fit.

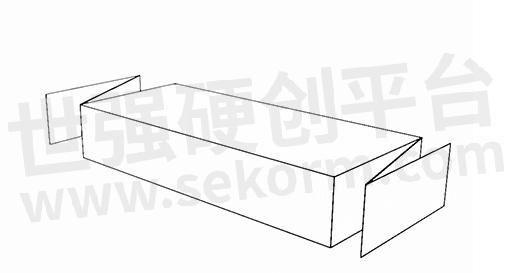

4. Linear Magnetic Ram (LMR) Motors

Linear Magnetic Ram (LMR) is one of the latest additions to the haptics industry. Based on solid-state magnetic suspension technology, it works by driving a suspended mass through a magnetic field. This movement is controlled by an electric current, which can be adjusted to change the position, speed, and force of the mass. This allows for precise control over haptic feedback.

An LMR Motor

What sets LMRs apart from other haptic actuators in the market is their wideband capability, with the ability to cover anything from 10Hz – 300Hz. They also use no springs or flexures, which makes them more durable than other haptic motors in the market. Moreover, they consume significantly less power compared to LRAs and ERMs, making them a more efficient choice for haptic motors.

LMRs are extremely versatile and can be utilized in a wide range of applications. These include gaming controllers, VR/XR peripherals, wearable technology, and in the automotive industry.

- +1 Like

- Add to Favorites

Recommend

- Nidec Develops CA Series Linear Vibration Motors with Smallest-class Diameters in the World

- Epson Develops New 3-Axis Vibration Sensors for Dam and River Floodgate Equipment Monitoring

- Skydio’s Autonomous Drone”X10” Adopted Nidec Motors

- Haptic Motors Clustered Haptic Arrays by TITAN Haptics Clusters Unlock New Possibilities

- Epson Develops the Ideal IMU for Attitude and Vibration Control

- Nidec Develops the World’s Thinnest-class Linear Vibration Motor “Slider“, with Thinness of 2mm and 40% Less Volume

- How to Prevent the Bad Phenomenon of Crystal Vibration?

- Delta 3-Phase Brushless DC Motor Fan, with Optimized Blade Design for High Efficiency and Low vibration

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.