Hyperboloid Technology and Rugged Materials Protect Signal Integrity in Data-driven Applications

OPTIMIZING ETHERNET LINKS

Data-driven applications that operate in harsh environments, including radar processing, intelligence surveillance and reconnaissance (ISR), and multi-function digital display processors, require high-speed and intensive computing power together with an adequate level of signal integrity. Organizations began to replace low-speed telecommunication systems with high-speed equipment around 10 years ago. As the market evolves, more innovative interconnects have become available to serve these upgrade initiatives.

Select materials, superior contact technology, and regulatory compliance help assure designers that high-speed connectors are rigorously qualified for severe environments. Any discussion of signal performance in harsh environments should include space applications. Interconnect solutions specified for space applications must ensure durability, reliability, and low outgassing, and meet the VPX computer bus standard (VITA 46) that is becoming the standard of choice for high-performing defense systems.

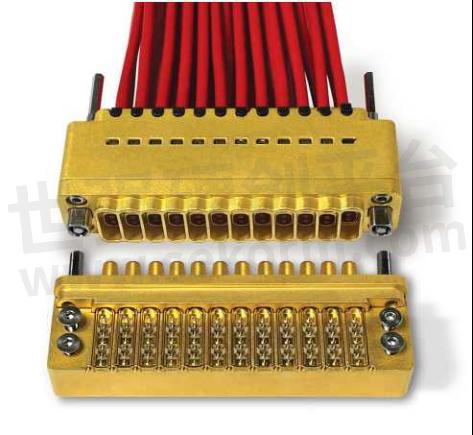

Smiths Interconnect's NXS Series is an advaneed high-speed, high-density interconnect equipped with the proven Hypertac hyperboloid contact technology to withstand data rate application requirements up to 10Gb/s (per channel), including extreme levels of vibration, shock, and climatic testing above 2100G. Each ultra-high density quadrax module contains 2 dual twinax at 100 Q each pair. This ultra-high contact density and compact form factor enables a 90° transition within a very small footprint. It is blind mateable, hot pluggable, with ultra-low mating forces and low outgassing materials.

Smiths Interconnect's KVPX Series is a shielded, high-density, high-speed, modular interconnect system optimized for differential pair architectures on a 1.8 mm x 1.35 mm grid. The backplane modules are available in 8 and 16 row increments on a 1.8 mm x 1.8 mm grid, with user-configurable keying and integrated stainless steel guide pin/keys. The KVPX Series was designed to complement the product offering for the VPX market. It serves data-intensive applications where high throughput and high computes are the critical factors: intelligence, surveillance and reconnaissance(ISR), signals intelligence (SIGINT), radar applications, and electronic counter measures(ECM).

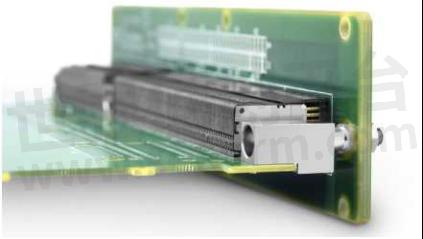

Satellite manufacturers often use large singular printed circuit boards featuring very high value components. Selecting a solderless PCB mount design allows the cormector to be placed and replaced with very low risk to the board, reducing the cost of ownership. The connector is mounted after reflow and has no impact on nearby components. Each product is engineered using 3D electromagnetic simulation (EM) software to provide excellent performance in a total thin film process.

A common practice in the industry is to rate connectors based on insertion loss; the frequency where the connector's insert! On loss reaches -3db is accepted as a threshold, since at -3db, half of the power is lost in the connector. This frequency is referred to as the first harmonic frequency of the maximum data rate; to find the data rate it would support, it is multiplied by two. Based on this methodology the KVPX connector, which does not reach -3 db until after 8 GHz is able to support high-speed signals of data rates up to 16Gb/s.

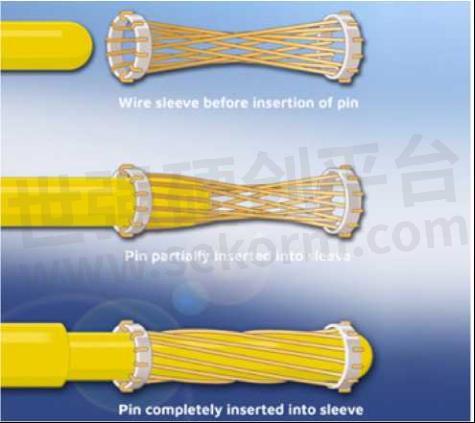

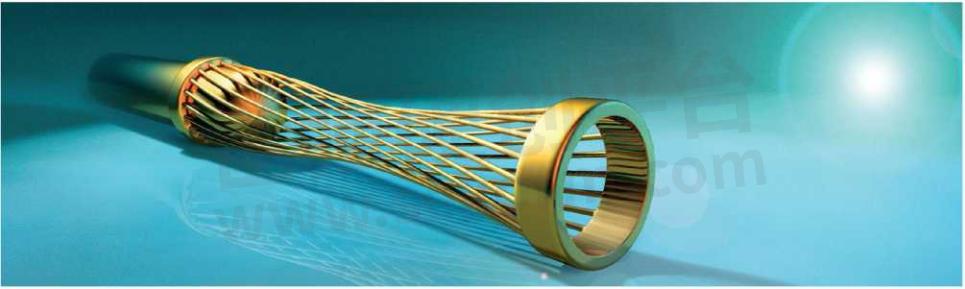

Smiths Interconnects Hypertac hyperboloid contact technology is designed for use in demanding environments where reliability and safety are critical. The shape of the contact sleeve is formed by hyperbolically arranged contact wires, which align themselves elastically as contact lines around the pin, providing several linear contact paths.

Hyperboloid contact technology provides immunity to shock and vibration fretting, numerous linear paths ofc on tact, low-insertion forces, high mating cycles, and a self-wiping cleaning action that results in consistently better integrity in extreme environments. Hyperboloid contact technology offers multiple points of contact, resulting in reduced wear and contact resistance thanks to its unique feature where a wired cage elastically winds the pin of the connector. This ensures more points of contact active also in harsh situations, as well as in comparable softness of mating. In addition, connectors with a flexible modular design, such as the KVPX Series, can serve standard 3U and 6U as well as custom configurations.

The low mass and low inertia of its wires enable it to follow the most abrupt or extreme excursions of the pin without the loss of contact. The contact area extends 360° around the pin and is uniform over its entire length. The 3-dimensional symmetry of the hyperboloid contact design guarantees electrical continuity regardless of the direction or intensity of external or internal forces.

In applications where continuity interruption or fretting on the contacts due to shock and vibration is a key concern, the use of hyperboloid contact technology together with selected rugged materials ensures electrical integrity even under the most demanding conditions.

Hypertac hyperboloid multiple line contacts provide far greater contact area than other contacts of comparable size. The wiping action of wires ensures a clean and polished contact surface.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.