Fiber Optic Connectors Glass vs. Copper

Fibre Channel is fast becoming the gigabit-per-second interconnect technology of choice for high-speed system designers. It performs extremely well for storage, networks, video, data acquisition and many other applications. Fibre Channel is ideal for reliable, highspeed transfer of digital audio/video signals. Currently, aerospace design engineers are using Fibre Channel for highly reliable, real-time networking, as well as for low-latency, high-throughput signal processing applications. Fibre Channel interface products are available in both Fiber Optic and copper based formats.

Fiber optic technology is simply a method of carrying information from one point to another in the form of light utilizing a thin strand of glass or plastic that serves as the transmission medium over which the information passes. Since the data is being transmitted with light pulses, as opposed to electrical current, there are several key advantages that make fiber optics attractive in applications ranging from telephony to computers to aircraft.

One of the most beneficial advantages is the extremely wide bandwidth, which allows for increased information-carrying capacity. The practical bandwidth of fiber optic cables far exceeds that of copper cable assemblies. Using optical fibers also helps to minimize attenuation in your system. As a signal travels along a transmission medium, either copper or fiber, the signal will naturally lose strength. In a copper wire, the attenuation increases as the frequency of the information signal increases. However, the attenuation in an optical fiber is virtually flat up until very high frequencies.

Unless properly shielded, copper conductors can have problems with Electromagnetic Interference (EMI) affecting the data signal. Any exposed copper conductor can act as an antenna, depending on its length, that will either radiate or receive energy. Proper impedance matching and continuous enclosure solves this problem. However, susceptibility is completely eliminated by using fiber optics, which is immune to EMI and crosstalk. Fiber optics is considered one of the most highly secure transmission methods available.

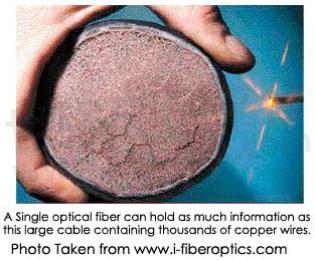

Another advantage of fiber optics is its small size and weight. Copper wires require more lines than fiber for the same transmission capacity. The reduced number of lines allows for maximum space utilization. This is extremely important in the commercial aircraft industry, since every pound can translate into increased operating costs.

Fibre Channel transceivers can also be driven with true differential pair twinaxial signaling with 150-ohm impedance between conductors. A true twinaxial Connector interface ensures signal integrity thereby minimizing jitter and data rate errors that will inevitably degrade the high-speed digital signal.

For both glass and copper applications, Smiths Interconnect offers ruggedized interconnect and cable assembly solutions with expanded beam or butt-joint fiber optic contacts as well as a complete series of differential pair twinaxial solutions offering the utmost in high speed matched impedance data-on-demand applications.

Making the decision between Fiber Optic or copper based Fibre Channel requires the designer to balance the benefits of each transmission media. Fiber optic based systems carry the benefits of wide bandwidth, low loss, EMI immunity, and long transmission lengths; however, the component cost is higher when compared to copper. Copper based systems are considered extremely rugged (especially during installation), low cost, and have been used successfully in helicopter and fighter aircraft applications. Smiths Interconnect offers both systems utilizing MIL-DTL-38999, ARINC 404 and 600, and MIL-DTL-83527 connector formats.

- +1 Like

- Add to Favorites

Recommend

- Terminal Connection Method of Electrical Connectors

- Kinghelm FFC/FPC Connector KH-FG1.0-H2.0-24PIN High-Performance Connector Solves Your Internal Connection Issues in Electronic Devices

- Advantages of Smiths Interconnect EMI Filter Connector and Filtered EMP Connectors

- Some Common Connection Methods of Industrial Connectors

- In-depth Understanding of the Connection Types of Industrial Connectors

- Kinghelm Type-A Connector KH-CP3.5AF180CB-14JB-STM with USB Connection Standards Leading the Trend of Connectivity

- Kinghelm KH-SIM1616-6PIN MicroSIM Card Connector, A Top-tier Self-ejecting MicroSIM Card Connector Featuring 6 Pins

- Kinghelm‘s VH Connector KH-VH-3P-Z with 3.96mm Pitch Is A High-performance Connectivity Solution Due to Its Reliability and Durability

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.