Introduction to Devcon® Epoxy Adhesives that Meet the Most Extreme Requirements

Introduction to Epoxy Adhesives

Adhesives are well known for being great alternatives to the traditionally used mechanical fasteners. Adhesives allow the joining of dissimilar substrates as well as help meet key design requirements including long-term durability, outstanding environmental resistance, and cleaner aesthetics. The Devcon range of epoxy adhesives, sometimes referred to as epoxy glue, includes a comprehensive range of products that meet the most extreme requirements.

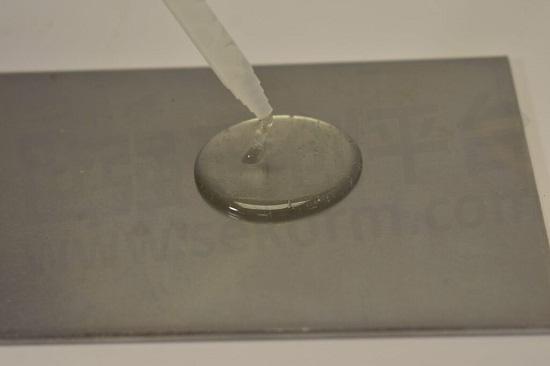

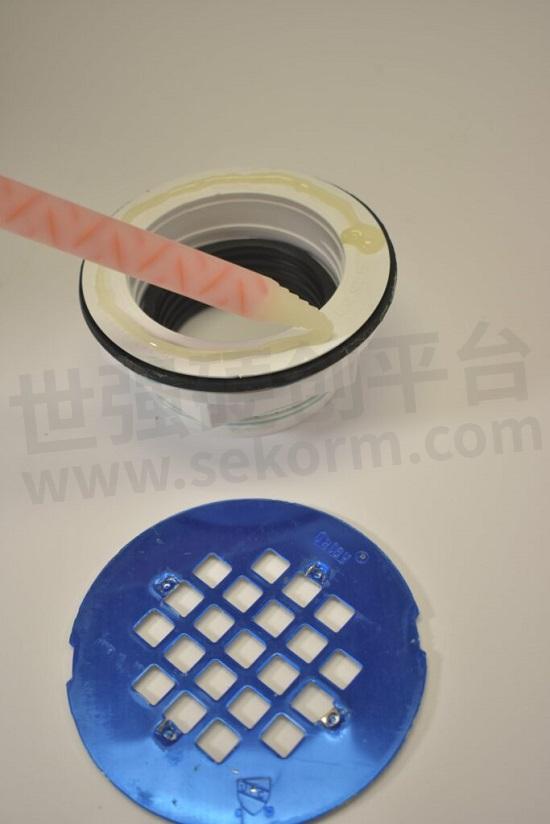

Devcon epoxy adhesives are available in a variety of curing times to suit the desired workflow. They have good temperature resistance as well as excellent chemical resistance. There is even a Devcon epoxy for bonding in wet environments or under water as bonding with adhesive in water is a unique but important application.

Industrial adhesives play an important role in a wide range of manufacturing processes. Among the wide range of adhesive types, epoxy adhesives remain very versatile and indispensable materials. They are extensively used in sectors such as aerospace, automotive, heavy industry, construction, maintenance, and repair, and marine. With outstanding mechanical properties and high bonding strength, epoxies can be used to fixture a wide range of materials from metal to glass. Epoxies can work in the harshest environments as they can be designed to withstand extreme temperature ranges, dynamic vibrations, and chemical exposure.

Epoxy Technology

Epoxy adhesives can be found in both one and two-part mix ratio systems, where they both contain a resin and hardener. When mixed, or cured, they undergo a chemical reaction that creates a strong and durable bond. With a combination of heat, chemical, and weather resistance, and high bonding strengths, epoxy adhesive protective coatings are ideal for a variety of applications.

New formulations continue to evolve, addressing specific requirements like flexibility, rapid curing, and environmental friendliness.

Devcon Solutions

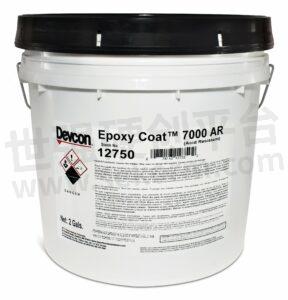

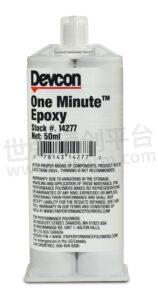

There is a wide range of Devcon epoxy adhesives that can be selected based on the specific application needs: Devcon 1 Minute Epoxy Gel for fast fixturing or Devcon 2 Ton® Epoxy for tough and durable applications. The Devcon two-part liquid epoxy adhesives and protective coatings can be easily applied manually or with various standard dispensing equipment. Devcon can be applied on vertical surfaces without sagging, as seen with Devcon 5 Minute® Epoxy Gel. For chemical resistance, Devcon Epoxy Plus 25, Devcon HP 250, and Devcon Epoxy Coat™ 7000 AR are flexible and resist glycols, oils, mineral spirits, and a variety of other chemicals.

Conclusion

When choosing an epoxy adhesive or protective coating for your application, Devcon adhesives are the solutions to consider as they are designed to adhere to a variety of substrates (with minimum surface preparation) and in the most extreme situations.

- +1 Like

- Add to Favorites

Recommend

- Devcon® Coatings Protect Surfaces from Impact and Reduce Equipment Downtime

- Devcon® Coatings Protect Assets from Harsh Chemical Environments

- Devcon® DFense Blok® Repairs and Protects Cyclone Pipe Elbow at Aggregate Facility

- Devcon® Putties Repair & Protect Pipe Header from Corrosive Salt Water

- Devcon® Titanium Putty & Devcon® Brushable Ceramic Coatings Repair & Protect Pressure Vessel from Corrosion

- Use of Adhesives in an EV Battery

- Rubber Repair with Polyurethane Coatings

- Devcon® Floor Patch™ Coating Good as New, Even After One Year of Heavy-Duty Service

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.