Virtual Antenna®, the clear winner over PCB trace in reducing hardware iterations

Traditionally, antenna designers have grappled with the demanding task of maintaining high RF performance throughout the product design process without altering the antenna’s geometry or the matching network. However, with Ignion’s Virtual Antenna® technology, we have unlocked a game-changing solution that maintains superior performance without the need for intricate changes during the design process.

This is relevant for most IoT device development where the initial form factor and dimensions typically change, affecting the RF performance resulting in redesigns of the antenna solutions. Device designers on tight schedules often opt for using ready-made IoT modules with antennas embedded, and then typically mounted on a bigger main PCB. While the IoT module antenna might perform well in isolation, the RF performance can get significantly affected by integration with the main PCB.

Here's why Virtual Antenna® components are the preferred choice for resilient antenna systems:

Preserving Performance: Virtual Antenna® technology allows us to maintain performance consistency across various device dimensions without modifying the antenna’s structure or the matching network. This means that if requirement changes occur or if using a module is mounted on a main PCB, you can expect the same high-quality performance consistently.

Cost-Efficiency: With Virtual Antenna® technology, we maximize the utilization of the existing Bill of Materials (BoM). This minimizes the need for expensive alterations and ensures that your antenna system remains budget-friendly even if hardware changes occur while delivering exceptional results.

Virtual Antenna® technology, far more resilient than PCB trace monopole antenna – the analysis of different ground plane sizes

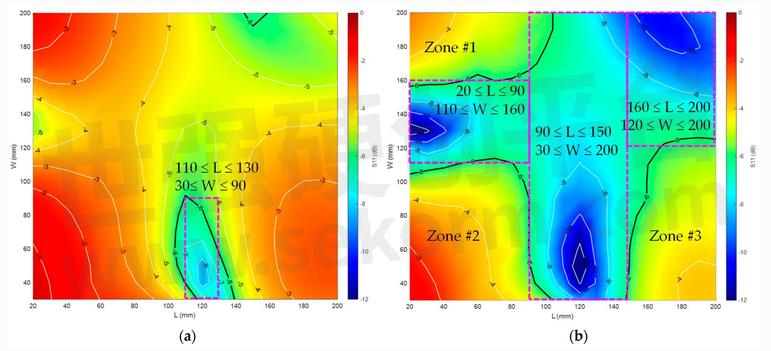

The performance of the Virtual Antenna® technology and PCB trace monopole antenna has been analyzed under the same challenging conditions including ground planes ranging from a small ground plane of 20 mm x 30 mm up to 200 mm x 20 mm. The figure below illustrates the worst S11 reflection coefficient in both antenna systems between 863 to 928 MHz while keeping the same BoM (antenna part and matching network) for both cases. The maps demonstrate that Virtual Antenna® technology is far less affected when modifying the ground plane dimensions of the IoT device. In particular, for the PCB trace monopole antenna, only 4.6% of the devices satisfy a S11<-6dB threshold. However, such reuse increases to 53.8% for the Virtual Antenna®.

Figure: Worst S11 in the 863–928 MHz frequency range for the PCB trace monopole antenna (a) and Virtual Antenna® component (b) as a function of the length L and width W of the ground plane. Both designs are embedded on a small 20 mm x 11 mm clearance area.

In practical terms, when embarking on the journey of developing an IoT device, designing with Virtual Antenna® technology offers greater resilience and flexibility compared to PCB trace antennas. Very few projects end up being exactly as planned, meaning that using a resilient antenna technology will save you costly design iterations. Typically, just one extra hardware spin can cause several months of delay due to production and bring-up time.

To try using Virtual Antenna® technology today, visit the free-to-use Antenna Intelligence Cloud™ tool.

- +1 Like

- Add to Favorites

Recommend

- NeuronicWorks Partners with Ignion to Accelerate IoT Device Designs with Virtual Antenna® Solution

- Virtual Antenna® technology: Discover the secrets of thousands IoT product engineers

- AI & Machine Learning: Simplifying IoT Antenna Integration with Virtual Antenna® Technology

- Safer Journey Awaits: Igniting Road Safety with Virtual Antenna® Technology

- Revolutionary Virtual Antenna® Solution for Revolutionary Ski Boot Design

- Ignion Offers Reliable Antenna Performance for Cold Chain Asset Trackers even in -40℃

- Ignion Announces the Smallest Virtual Antenna™ at the Wi-Fi World Congress Which is with a size of only 3x2x0.8mm

- Ignion’s Antenna Solutions Facilitate IoT Applications to Achieve Sustainable Consumption

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.