ATP Customizes PowerProtector Firmware in Solid State Drives(SSDs) for a Leading Aerospace Company

ATP Customizes PowerProtector Firmware to Better Address Sudden Power-Off Scenarios

Power outages and glitches, no matter how short, can compromise data integrity. Solid state drives (SSDs) are particularly vulnerable, as data management involves operations happening in the background. A power loss will interrupt the operations and adversely impact data.

In a normal system shutdown, data temporarily stored in volatile memory (DRAM) is “flushed” to non-volatile memory (e.g., SSD or any storage device), so the data is kept safely stored before power is removed. It also ensures that the mapping tables, which keep track of logical block addresses in relation to physical flash pages, are updated.

ATP PowerProtector Overview

To protect data during a power loss event, ATP SSDs include PowerProtector, which integrates hardware design and firmware algorithms. ATP PowerProtector features a power loss detection circuit. As soon as it detects a power drop below the threshold voltage (Vth), the power protection mechanism triggers a “flush cache” and the SSD uses up reserve power from capacitors to complete the last Read, Write or Block Erase operation, while simultaneously stopping the controller from sending data to the flash chip to make sure that no data is lost in transit.

The default threshold voltage is less than 4 volts (Vth <4.0 V). In a sudden power loss condition, the drive then enters the “while loop,” which allows data in the DRAM cache to be saved to the flash while protecting previously saved data from errors. The original firmware waits until the host’s power reaches 0 V and reboots as soon as power returns.

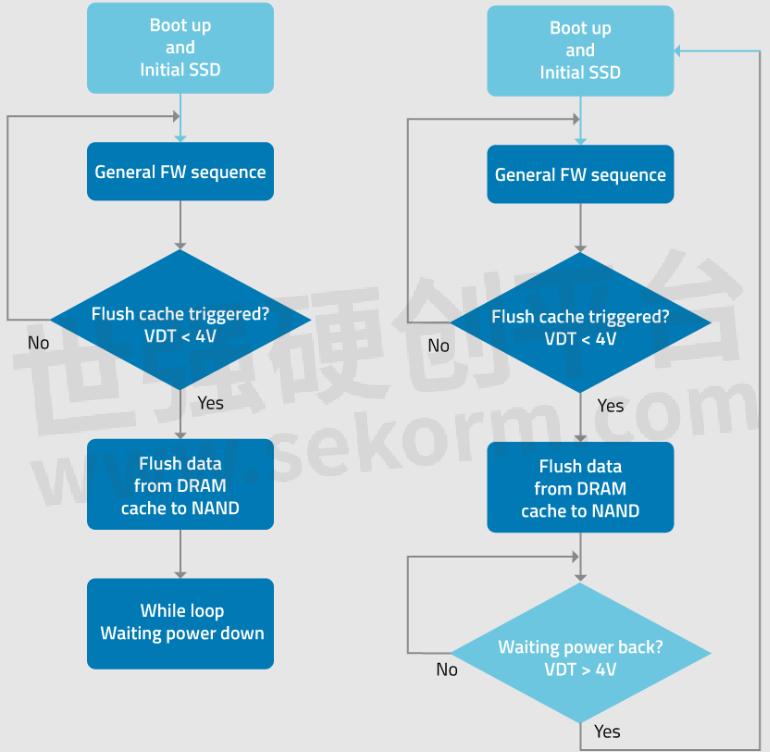

The figure below illustrates the “while loop” and shows the flow of the original firmware.

Figure 1. Original ATP PowerProtector firmware flow

Customer Case: The “Endless While Loop”

One of ATP’s customers needed 2.5” SSDs for a leading aerospace company. Due to the critical nature of aerospace applications, they needed highly reliable storage devices with a strong power loss protection mechanism. During testing, they subjected the ATP SSDs to several power interruption intervals to simulate unstable power conditions during transition periods in power charging systems.

Typically, the customer’s systems will have power interruptions ranging from 25 ms to 450 ms during these transitions that last about 5 seconds.

They found that if the power loss at Vth <4 V lasted less than 100 milliseconds (<100 ms), the firmware kept running and entered an “endless while loop” even after DRAM data had been completely flushed, thus depleting the capacitors’ reserve power. The loop could be terminated only by performing a complete power shutdown. Upon power on, the host can no longer recognize the SSD unless a system reboot is performed. This issue did not arise in power loss intervals that lasted from 100 ms or longer.

ATP’s Out-of-the-Box Response

Recognizing that customers have different requirements and operational scenarios, ATP decided to develop a customized firmware suitable for this customer’s unique power conditions.

In the original firmware, the drive stays in a “while loop” even after DRAM flushing if the power interruption was <100 ms and stops only when the power supply is completely off (0 V). With the new firmware, the power loss protection mechanism is triggered at the same Vt level of <4, but as soon as the power supply reaches >4 V, the “while loop” stage terminates, and the SSD reboots. This enhancement addressed the issue of the SSD going into an endless while loop whenever the power interruption was shorter than 100 ms.

The figure below shows the flow comparison between the original and new firmware.

Figure 2. Comparison flow of ATP PowerProtector original firmware and the new, improved firmware

Conclusion

To verify the new firmware, ATP performed tests at three different temperature levels, namely -20℃, 25℃, and 70℃.

The new firmware passed the customer’s cumulative test criteria of >2,000 cycles at room temperature and high/low temperature. The new firmware improves the reliability of ATP SSDs and the customer was very satisfied with the solution provided by ATP.

ATP has been trusted by industry leaders for nearly three decades. As a true manufacturer, ATP takes charge of all stages of the manufacturing process starting from the IC, up to the module and mass production level. In this specific case, ATP harnessed its in-house expertise to deliver a tailor-made solution that showcased ATP’s advantage of flexibility when it comes to addressing the unique challenges and requirements that turn-key solutions may not be able to address.

- +1 Like

- Add to Favorites

Recommend

- SMART’s DuraFlash N200 SATA 2.5” Solid State Drives Provide Economic Yet Highly Reliable Mass Storage

- SMART’s DuraFlash ME2 SATA 2.5” Solid State Drives Offer Highly Reliable Mass Storage with 3D NAND Technology

- SMART’s DuraFlash CS210 SATA 2.5” Solid State Drives are Designed for General-purpose Industrial Applications

- SMART‘s DuraFlash R800 SATA M.2 2280 Solid State Drives,available in both Commercial and Industrial Temperature Ranges

- T5PF 2.5”SATA Solid State Drives With FIPS 140-2 Compliance Deliver High Performance

- T5PFLC 2.5″ and M.2 2280 SATA Solid State Drives (SSDs) Come Equipped with FIPS 140-2 Encryption Capabilities

- What Is a Semi-Solid State Battery?

- ATP Rapid Diagnostic Test (RDT): Accelerating Failure to Maximize Reliability and Endurance

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.