What Are Some Common Misconceptions About IDC Sockets?

IDC Sockets are a type of electrical connector that plays an important role in the maintenance of various types of electronic equipment. Unfortunately, some people have misunderstandings about these sockets, perhaps because of their names. They may think of them as a type of machinery that doesn't require any manual labor. However, this is not the case—you still need to use your hands to install IDC sockets. Additionally, this isn't a type of fastener that's meant to be reused. In other words, it's not designed to be unscrewed and reconnected without replacement.

How Does an IDC Socket Enable Efficient Repair and Replacement of Connectors?

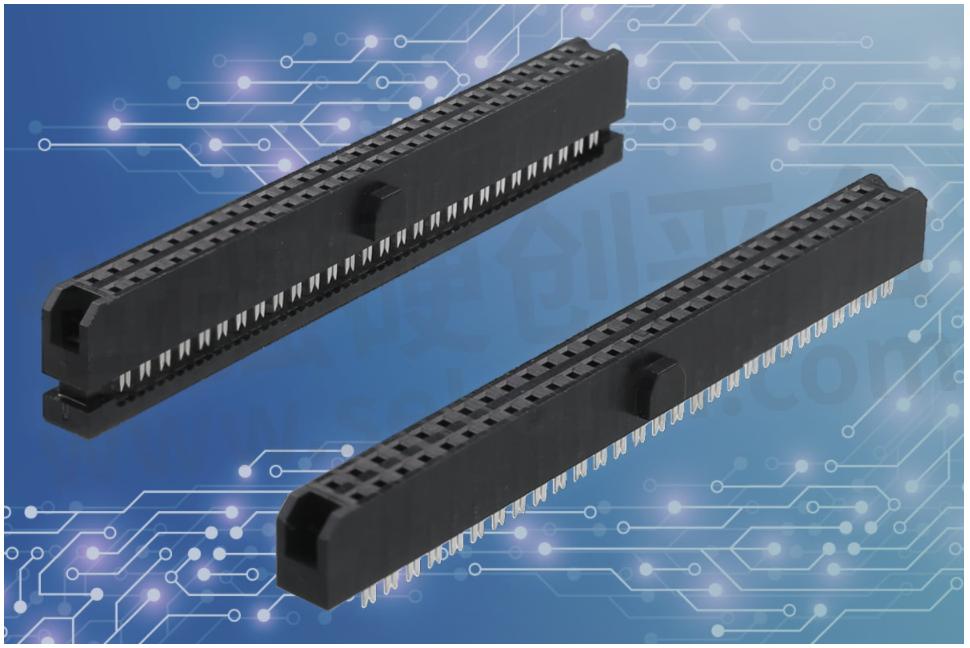

Installing an IDC socket requires considerable skill and precision. This connector involves using metal tabs that are connected to wires with insulated insulation. These metal tabs attach to the wire insulation and are then inserted into a specialized small socket. This creates the metal-to-metal contact needed for an electrical connection.

The advantage of using an IDC socket is that it makes it extremely easy to repair and replace all sorts of connectors. This is because you don't need to worry about stripping and attaching new wires to the socket—all you need to do is disconnect the old socket and insert the new one. This makes maintenance processes a lot quicker and simpler. Additionally, the ability to replace a failed component on the spot, without having to wait for replacement parts or repair services, can lead to fewer interruptions in production.

What Are the Benefits of Using an IDC Socket?

The primary benefit of using an IDC socket is its cost efficiency. The connector can be bought in bulk at a lower price compared to other types of connectors. Additionally, the speed of installation is also noteworthy. In most cases, it takes less than a minute to install an IDC socket, compared to hours or days for more complex connectors.

Furthermore, IDC sockets are designed to be reliable and durable. They can withstand strong vibrations and extreme temperatures, and their metal-to-metal contacts are reliable even in harsh environments. Finally, these connectors are available in a variety of sizes and shapes, making it easy to find one that fits a particular application.

In conclusion, IDC sockets are an important tool for electronic device repair and maintenance. They enable fast, cost-efficient installation that's reliable and durable, making them a must-have for any electronic technician. Understanding the advantages of using an IDC socket can go a long way toward keeping your devices up and running.

- +1 Like

- Add to Favorites

Recommend

- The Recent Advancement of IDC Socket Technology in Telecommunications and Data Processing

- What is IDC D-Sub Connectors ?

- The Features of the Good Price and Quality 10pin IDC Ribbon Cable Connectors

- TE Connectivity Debuts Next-generation Server Sockets and Connectors to Support Advanced Data Center and Edge Computing Applications

- Kinghelm KH-2.54PH180-2X8P-L8.9 IDC Connector:The Future of High-Density Connections

- Kinghelm IDC 2.54mm Connector KH-2.54PH180-2X13P-L8.9 with the Current Rating of 3A

- A Paradigm Shift in Simulation Techniques of Semiconductor Test Sockets

- Greenconn荣获邓白氏企业认证,实力彰显行业领先水平

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.