ept Board-to-Board Connectors for Industrial Sensors And Camera Systems

Miniaturization, high-speed data transfer rate, and robustness: Current industrial automation trends pose more and more challenges for sensors and camera systems, as well as for their installed components. Therefore, various criteria must be observed depending on the area of application when choosing the right connectors.

Current Trends in the field of sensor and camera technology

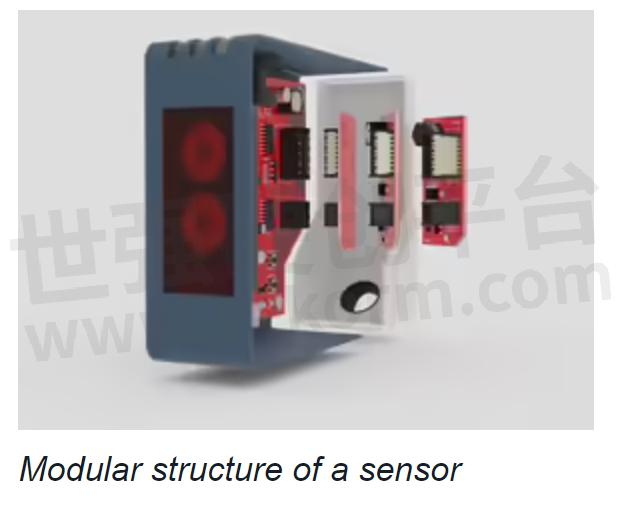

The increasingly popular modularization trend and Industry 4.0 have a significant influence on the field of sensor and camera technology. Sensors are typically designed to be modular these days in order to save on costs related to development and product realization. The housings are standardized, and the sensor’s functionality is defined in the process. Variable PCBs can be combined individually with the help of rectangular or mezzanine connections (Fig. 1). The standardized type offers the user the advantage of uniform handling during assembly and commissioning and when using the sensor.

Furthermore, sensors and cameras for the field of industrial automation are becoming increasingly more intelligent. Which is why additional functions are being integrated into the devices, in addition to their built-in measuring function:

Enhanced diagnostic functions for monitoring the durability of the sensor technology and detecting faults

Sensor parameterization

Remote maintenance

Communication from the sensor to the cloud and integration of bus or IO-Link functionalities

Requirements for modern sensors and camera systems

The result of these trends is that modern sensors and camera systems are subject to certain requirements that naturally entail implications for the connectors that are to be installed subsequently:

High degree of miniaturization

Secure high-speed transmission

Good electromagnetic compatibility (EMC)

Protection in adverse environmental conditions

Pronounced durability

Choosing the right connector

Things such as sensors and camera systems, which are used in close proximity to machines, are exposed to particularly harsh environmental influences. While it is true that overmolding the electronics can protect them from these external influences, an additional, appropriate overmold that is compatible with the connection solution is also required. This often poses a problem for standard connectors, as the vulnerable mating area in particular must be protected from the overmolding material, and the commonly used pin and socket contact does not provide the necessary IP protection class for these materials.

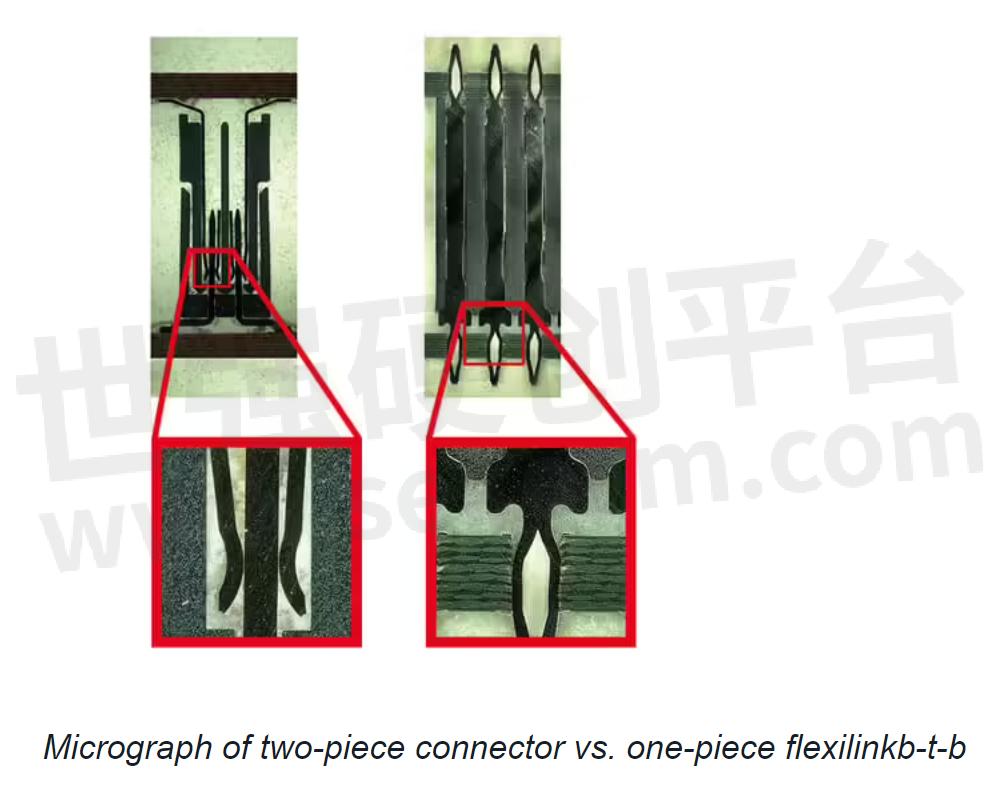

Choosing a one-piece connection solution, however, is a way to guarantee the required degree of reliability – in other words, a connector that does not require the conventional mating area. This provides for a durable and robust connection solution whose contact area cannot be penetrated by the overmold material (Fig. 2).

For areas of application that place particular requirements on the robustness of the connector, we also recommend connecting the PCB using double-sided press-fit zones – a process that has been tried and tested a billion times over. A reliable mechanical as well as electrical board-to-board connection is created using just a single part. This means that time-consuming soldering work or expensive cable solutions can be avoided, and costs can be cut by up to 50 percent. By omitting the vulnerable mating area and using press-fit technology at the same time, a connector can withstand shock loads of 50–200 g without contact interruption.

Suitable connectors for sensor and camera systems

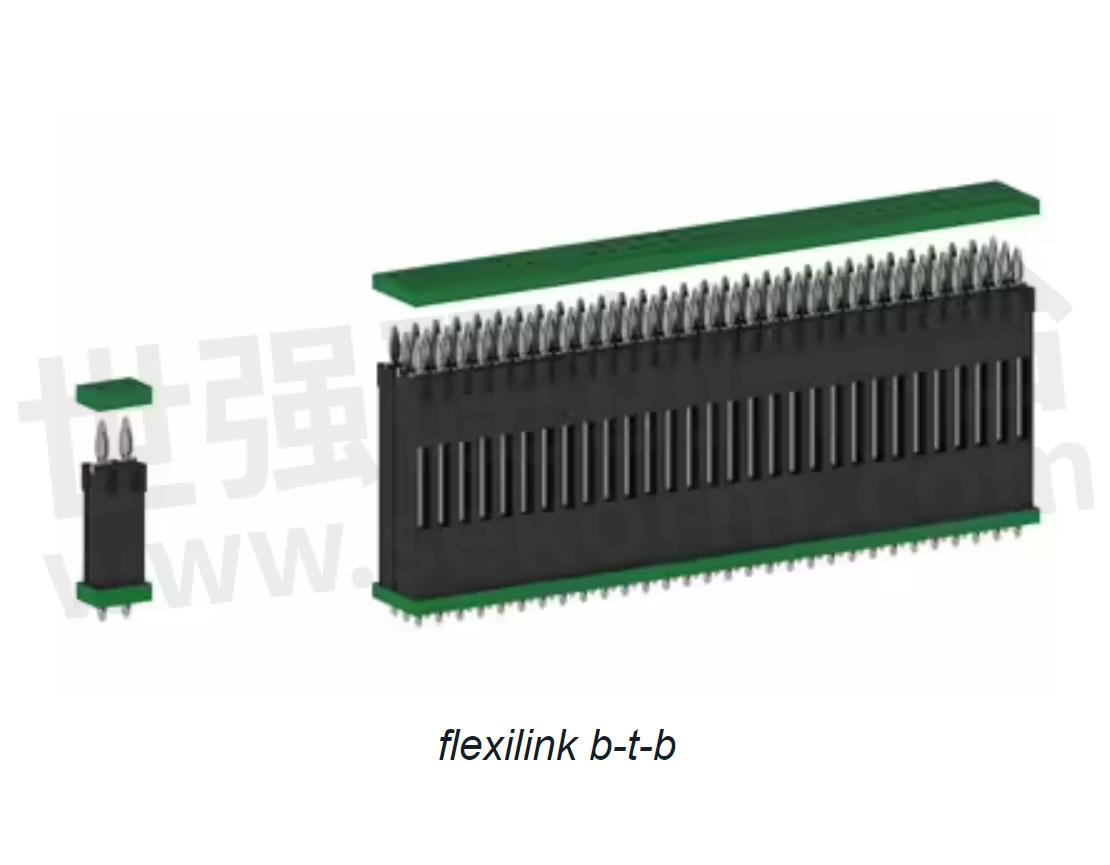

flexilinkb-t-b

ept flexilinkb-t-b connector fulfills these exact durability and reliability requirements and is also available with the tried and tested press-fit technology.

Conversely, both sensors and camera systems become more compact as their level of performance increases, which necessitates high-speed capabilities and miniaturization. Space-saving SMT solutions with a pitch of 0.5 to 0.8 mm are particularly suitable for miniaturized, high-performance applications.

The optimized, high-speed contact design of the Colibri PCB connector enables fast, interference-free signal transmission starting at 10 Gbps. Its optional shielding also protects against electromagnetic influences.

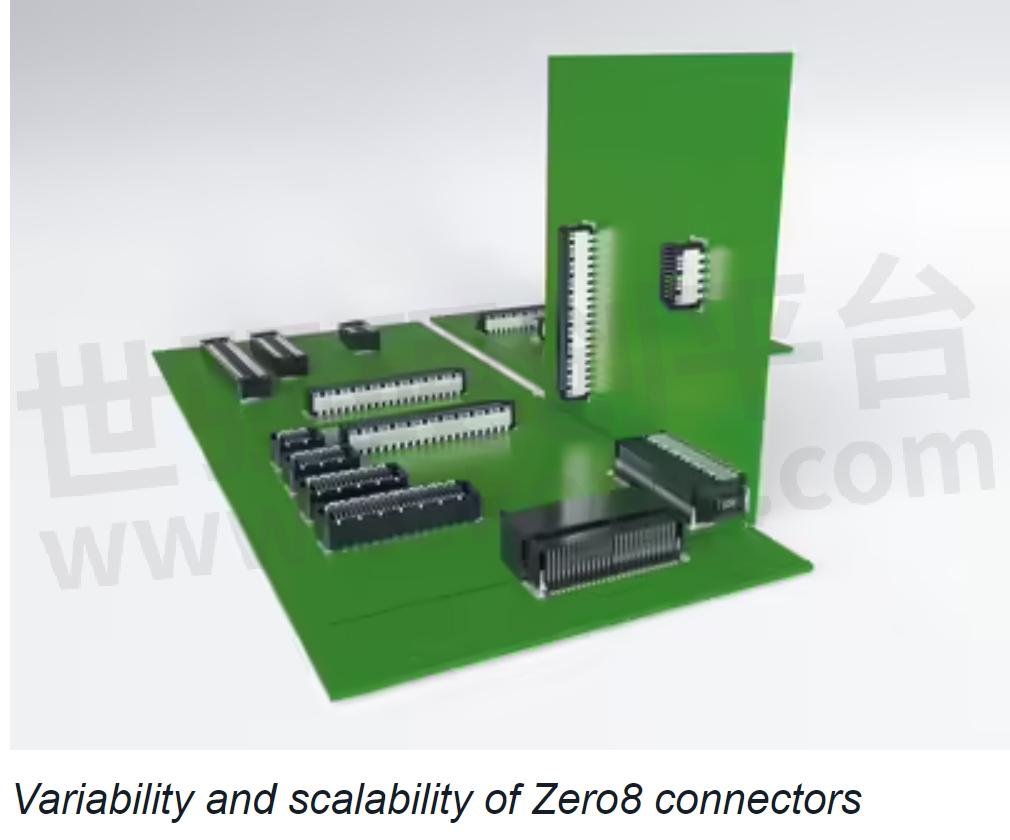

Known requirements for intelligent sensors include robustness, high-speed capability, and good EMC. We also recommend using a product that offers a wide array of different possible applications due to its modularity. Time-consuming release cycles can also be avoided, thereby saving time and money, if all of the connectors in a product range are compatible and can be freely combined with one another. A high degree of scalability enables developers to customize types, stack heights, and pin counts to meet their individual requirements. They can also choose between shielded or unshielded connectors, as well as connectors that are angled or straight.

Zero8

The Zero8 series SMT PCB connector reliably connects PCBs with data transfer rates of up to 16 Gbps and meets all of the requirements mentioned above.

- +1 Like

- Add to Favorites

Recommend

- ept Colibri® 0.5 mm-pitch SMT Connectors Colibri® 0.5 mm-Pitch SMT Connectors: Maximum Flexibility with Data Transfer Rates of Up to 16 Gbps

- ept One27® SMT PCB Connectors with a Pitch of 1.27mm is Suitable for Board-to-board Applications ∣ video

- ept 1.27mm-Pitch Straight One27® SMT PCB Connectors Available with Short Delivery Time

- ept Introduced Colibri 25+ Gbps High-Speed Connectors: Sample and S-parameters Access at Embedded World 2024

- ept Connector Selected for Use in the New Specification by the PICMG®

- ept Offers The Right Board-to-board Connectors To Meet The Shift In Automotive Electrical Systems

- ept’s 0.5 mm-Pitch Colibri® High-Speed SMT Connectors Are Optionally Available with a Thicker Gold Coating to Meet Extended Environmental Requirements

- Rosenberger Hochfrequenztechnik GmbH & Co. KG and ept GmbH Develop automotive Hybrid Connectors

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.