Reducing Retest Improves First Pass Yield (FPY) with PathWave Manufacturing Analytics

A contract manufacturing was able to reduce retest rates and significantly increase First Pass Yield ~50% by using the tools built into PathWave Manufacturing Analytics.

PathWave Manufacturing Analytics (PMA) provides a big data platform for performing time-series analytics on all kinds of test equipment in a manufacturing environment. In this customer success story, the contract manufacturer is utilizing KEYSIGHT's Cloud platform for hosting the analytics to speed deployment and reduce the upfront server infrastructure investment costs and maintenance. This allowed them to quickly deploy PMA for their manufacturing line and dig into the data in a matter of days.

Figure 1 is the volume by project with the project highlighted that was selected for investigation. It had a high retest rate, by volume, and a low First Pass Yield.

Figure 1: Volume by project showing the unique serial number counts for passing, retest, and failed boards.

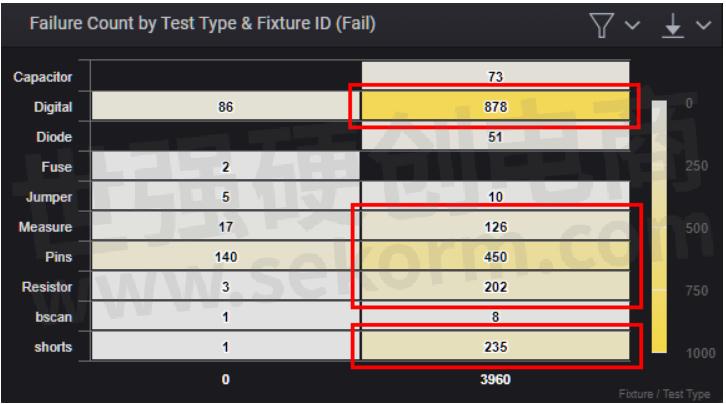

By simply selecting the project and then the Failure Count By Test Type by Fixture ID, the engineer was able to gain insights into the most frequently failing, and later passing, tests. The action was to take a look at the physical test equipment to inspect it. Since PMA can identify the tests and by extension the probes, with an optional probe heatmap, the engineer was able to find all the worn out probes that required replacement.

Figure 2: Pareto of the highest failing test names to drill into.

In conclusion, using one of the tools in PMA to drill into retest and failing tests the engineer was able to take corrective action and identify the root cause of the test equipment issues.

- +1 Like

- Add to Favorites

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.

Recommend

PMA‘s DPAT Implementation Safeguards Against Potential Yield Losses

2023-08-12 - Manufacturer News With the advent of Electric vehicles (EVs), there is an increasing number of requests for incorporating DPAT into Keysight’s Pathwave Manufacturing Analytics (PMA) Dashboard for a more precise calculation of what to discard as fails and what to pass and ship out to end user.

Keysight‘s Production Data Analytics Software PWA Has Supported Cloud Service Operations and Software

2021-11-06 - Manufacturer News Keysight‘s production data analytics software PathWave Manufacturing Analytics (PMA) has supported cloud service operations and software as a service with historical data loading since its inception, along with its on-premise mode.

Keysight Technologies Acquires Quantum Benchmar, Augmenting Keysight‘s Quantum Portfolio

2021-06-16 - Manufacturer News Keysight Technologies, Inc. , a leading technology company that delivers advanced design and validation solutions to help accelerate innovation to connect and secure the world, announced today it has acquired Quantum Benchmark, a leader in error diagnostics, error suppression and performance validation software for quantum computing.

Loading data into PathWave Manufacturing Analytics

2022-05-07 - Application solution Article PathWave Manufacturing Analytics (PMA) is a backed by an experienced team of people at Keysight, who can help you achieve the goal of bringing in data from your manufacturing test equipment and software, for analysis and presentation, to help you to gain the necessary actionable insights that can be used from an operator on the line to the highest senior management levels of the business organization. PMA includes a scalable architecture that can grow with your business.

Boosting Your Manufacturing Analytics System with Keysight’s Pathwave Manufacturing Analytics (PMA)

2023-06-29 - Design Article With the recently launched feature that tracks all rework and scraps, PMA has helped manufacturers globally by working alongside their existing manufacturing systems to improve their cost of poor quality and leading towards lowering the defects of the test boards.

PathWave Manufacturing Analytics (PMA) Use Case: Faster diagnostics for Semiconductor recalls

2022-08-29 - Application solution Article Keysight has seen car recalls due to faulty semiconductor components. Within the PMA application, there is an RMA module that allows a user to retrieve the complete test history of the board and its batch.

10% Increase in ADAS PCBA Testing Throughput With the i3070 4-module Inline ICT and PathWave manufacturing analytics

November 10, 2022 - Case Study

I3070

PathWave Manufacturing Analytics License Management:Viewing and adding licenses with the license manager APPLICATION NOTE

April 22, 2020 - Application note & Design Guide

Global EMS Manufacturer Reduces Time to Market Using PathWave Manufacturing Analytics

June 4, 2019 - Case Study

Automate Intelligence: Jumpstart Operational Agility in Product Development

August, 2022 - Case Study

Root Cause Analysis on Return Merchandise Authorization (RMA) Boards

2021-11-25 - Design Article Sometimes early failure boards are returned to the factory for diagnostics,Keysight is going to talk about Root Cause Analysis on Return Merchandise Authorization (RMA) Boards.

Global EMS Manufacturer Reduces Time to Market Using Path Wave Manufacturing Analytics CASE STUDY

June 4, 2019, - Case Study

Electronic Mall

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Integrated Circuits

Discrete Components

Connectors & Structural Components

Assembly UnitModules & Accessories

Power Supplies & Power Modules

Electronic Materials

Instrumentation & Test Kit

Electrical Tools & Materials

Mechatronics

Processing & Customization