Nextron’s Next Generation QSFP112 cage/connector system and Heat Dissipation Strategies

Growing with the bandwidth demand of data center networks, QSFP modules have evolved from 200G (QSFP56) to 400G (QSFP112). QSFP112 is the next generation cage/connector system targeted to support 112Gb/s per lane and the stepping stone to 800G applications. While QSFP112 is totally backward compatible with QSFP56 and QSFP28 systems, it is the most cost-efficient way to upgrade bandwidth without rebuilding current network architecture.

Faster data transmission speed means greater heat generated in the process. Overheated devices are not only unstable in performance but also post threats to the safety of the entire system. Therefore, heat dissipation strategies of these higher-capacity receptacles are critical and must keep up pace. In this article we discuss 3 most popular types of thermal management.

Air Cooling Methods

As basic as it might sounds, heat sinks and heat pipes are still the most commonly seen methods of heat dissipation. These air cooling devices comes in different shapes and structures, but they all serve for the same purpose: to provide efficient and reliable cooling ability, dissipating up to 20W/pole in different configurations.

Aside from their heat dissipation capability, the overall size and cost-efficiency also defines whether a design of a heat sink or heat pipe is excellent or not.

Liquid Cooling Systems

Due to its physical property, liquids perform better thermal conductivity over air. In other words, liquid cooling can be a more efficient way of thermal management.

Some might say that the idea of having liquid flowing through server racks are daunting. However, with the ever-increasing standard of heat dissipation efficiency taking place in data centers, liquid cooling systems might become the better option either in the aspect of cost or safety.

Besides, higher thermal conductivity also means more precision in temperature control.

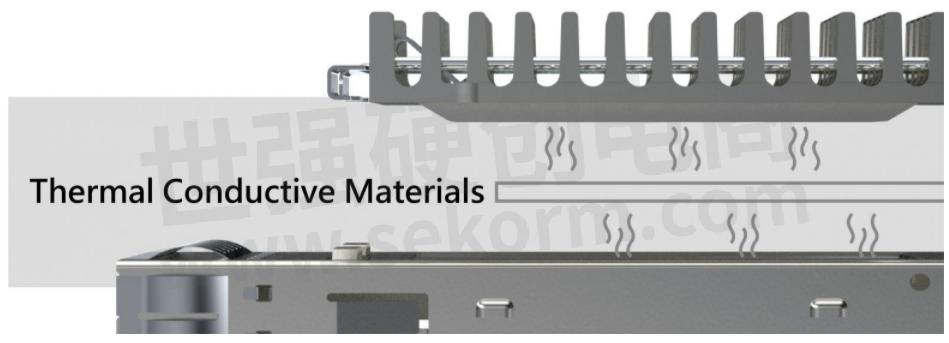

Thermal Conductive Material and Additions

For additional heat dissipation needs, special choice of thermal conductive materials, thermal pads / tapes and thermal interface coatings are suggested.

These additional materials should not only demonstrate their ability to dissipate heat efficiently but are also expected to withstand multiple insertions and removals without degrading performance.

Nextron QSFP112 Heat Dissipation Solutions

For decades, Nextron(正凌)has been a leading brand in high-speed I/O connectors, cages and modules. Along with the pursuit of faster data rates, heat dissipation methods of such products are also what Nextron has been heavily invested in.

Starting with thermal management simulations conducted by our in-house experts, Nextron's QSFP series are crafted with in-depth knowledge of material choice, structure design and manufacturing technology.

For both air cooling and liquid cooling systems, Nextron's solutions have been trusted by telecom giants around the globe. With Nextron, there will definitely be a perfect cooling solution for your infrastructure.

- +1 Like

- Add to Favorites

Recommend

- Nextron Nominated as Mechanical Design Best Practice in Ansys 2020 Innovation Conference

- Nextron‘s 1000BASE-T1 Automotive Ethernet Solution:4 way SPE circular connectors

- Nextron‘s Next-Gen High-Speed Connectors

- 3D Vapor Chambers: Revolutionary Heat Dissipation

- Nextron‘s Medical ATX Chassis: Design Excellence

- Nextron Collaborated with a Leading Benchmark Manufacturers of 3D mapping technology to Advance Medical Technology

- Nextron Taiwan Smart Factory Upgrade

- Nextron‘s SFP families I/O Connectors can Support Up to 50G while Data Rate can Reach Up to 400G for Backhaul Transmission

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.