Smiths Interconnect Has a Very Large Portfolio of Existing Coaxial Isolators and Circulators for Space or Defence Applications

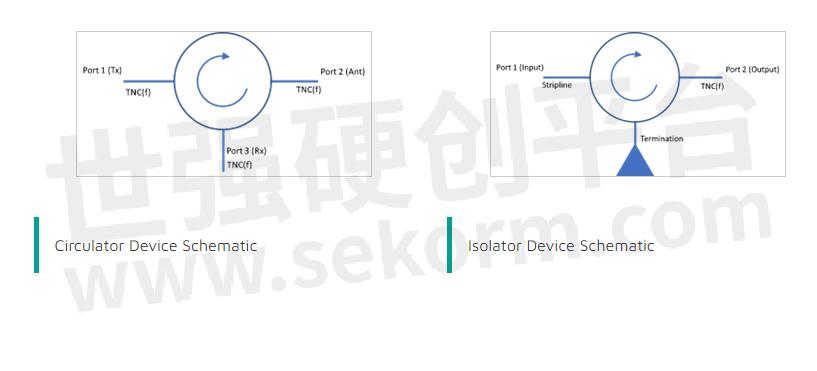

A coaxial circulator is a passive, non-reciprocal three-port device that allows microwave or radio-frequency signal to exit through the port directly after the one it entered. An isolator is a two-port device that transmits microwave or radio frequency power in one direction only, while the other direction is blocked. Isolators can be considered as a special case of circulators and are made by suitably terminating one port of the circulator ports.

Isolators and circulators are routinely used in communications and radar applications including AESA antenna, SSPAs, and signal processing equipment, and are generally available as Coaxial, Waveguide, stripline, or microstrip types.

coaxial isolators (and circulators) are the most common type of ferrite device available and produced by many companies. In its simplest form, a coaxial ferrite isolator offers reasonable performance, is readily reproducible, and importantly very easy to use. You’d be right to ask that given this ubiquity and simplicity “What is it that Smiths Interconnect coaxial devices offer that can’t be found elsewhere”?

Users expect an electrical performance that is stable over temperature and appropriately packaged so that the system is electrically stable, mechanically robust, and reliable within the intended application and environment. Smiths Interconnect isolators and circulators are designed and qualified to meet these expectations and comprise many features designed to meet these expectations as the following example illustrates.

Physically Smiths Interconnect’s isolators are like no other available. Most noticeable are the RF interconnects which are compliant with MIL-DTL-39012 but are integrally machined into the device housing; in other words, the housing and connectors form a monocoque structure that is not only incredibly robust but also allow the devices to be mechanically compact. Smiths Interconnect refers to these as solid connectors.

The device housing is made of a grade of Stainless Steel that optimizes and internalizes the magnetic field, reducing the radiated fields and eliminating the need for shielding plates. Typically, Smiths Interconnect devices are magnetically shielded to ~ 0.0005Am^2 in X-Ku-Band. As you could see behind an SMA connector’s PTFE insert the internal structure is arranged so that the PFTA dielectric is minimized making the dielectric that or air which allows the connector to function well above the frequency that SMA connectors normally operate, while maintaining exceptionally low insertion loss. For example, the Smiths Interconnect 22-25GHz SMA isolator has an insertion loss of 0.25dB over temperature which is a similar performance to the Smiths Interconnect 7.0-10.5GHz isolator.

A “solid” state connector is produced in-house, which saves costs, and delivery time and reduces risk. Most importantly however it means the mechanical housing can be smaller, as it no longer must be dimensioned to accommodate the connector flange and the screws used to secure it. Smiths Interconnect solid TNC connectors boast the same advantages as the solid SMA types and tend to be used where the RF power is too high for an SMA. Recently Smiths Interconnect successfully qualified an L-Band TNC circulator to 1.5kWpk and 225W average under full reflection (any phase) conditions (equivalent to 6.0kWpk and at least 450W of average power).

Because the housings are machined to very tight tolerances, Smiths Interconnect users can mount Smiths Interconnect devices on either of two faces thus ensuring the connector center contact is on the device center line. This is why Smiths Interconnect isolators tend to include a label on each side: if the isolator has two SMA (f) connectors it can be used as a clockwise (CW) and counterclockwise (CCW) device with the label prominently displayed and without requiring to be shimmed.

The internal structure (junction) is under rotational compression. This makes the device essentially immune to the effects of mechanical vibration and shock. This is not a new approach and has been used for over 40 years. What is new however is that the combination of the threaded lid and internal, patented grounding gasket virtually eliminates two of the contributions to the insertion loss.

Another feature is that there are no seams or joints, which means that Smiths Interconnect “solid” connectors are RF sealed “by design” and there is no need for conductive epoxy. In recent tests, Smiths Interconnect’s facility in Dundee, Scotland used Smiths Interconnect in-house reverberation chambers to demonstrate a shielding of more than 85dBi on SMA connectors at L to K-Band. Smiths Interconnect does not need to use any epoxies to RF seal the structure, but as a precaution, we treat the threaded lid using conductive epoxy to minimize the radiated electromagnetic fields.

Are you wondering how Smiths Interconnect attaches the center contacts to the center conductor? As it is impractical to solder the piece parts externally and pass the assembly into the cavity, we use a contactless induction soldering and inspect the resultant solder joints using a Smiths Interconnect in-house 3D x-ray machine, whose 160keV beam makes short work of up to 5mm of steel.

Most isolators are produced by terminating one of the ports depending on the users’ mechanical preferences. The terminations tend to be 50 Ohm rod resistors whose mechanical and electrical properties make them ideal for producing superbly well-matched impedances and ensuring excellent isolation that is repeatable and temperature stable.

A typical isolator construction is illustrated in the following simplified diagram.

Potential customers interested in knowing more about this and related capabilities may contact Smiths Interconnect to discuss their specific needs. Smiths Interconnect experienced technical staff will be pleased to detail the potential performances, and mechanical details, and share the fruits of Smiths Interconnect’s 40 years of experience designing and producing coaxial isolators and circulators.

For K, L, and X-Bands

Smiths Interconnect has a very large portfolio of existing coaxial isolators and circulators for Space or Defence applications and is designed to operate in assigned bands from 0.8 to 26.0GHz (SMA) and from 0.8 to 10GHz (TNC) depending on the operating power. Low-power devices are available in a variety of frequency-dependent packages with a bewildering range of connector and load, combinations.

- +1 Like

- Add to Favorites

Recommend

- How to choose Diplexer or Circulator?

- Kinghelm RF Coaxial Connector KH-SMA-K514-13N for Improving Wireless Communication Quality

- What is Waveguide to Coaxial Adapter?

- What Coaxial Cables Should We Use on Military Vehicles?

- Smiths Interconnect Has Extended Its Broad Range of Coaxial Coupler Components in UHF to Ku-Band

- Nextron‘s 1.0 mm 110GHz SMA Coaxial Connector

- A Quick Introduction to Coaxial Attenuators

- Smiths Interconnect Offered Isolators to Support NASA’s Europa Clipper Mission to Explore Jupiter’s Moon

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.