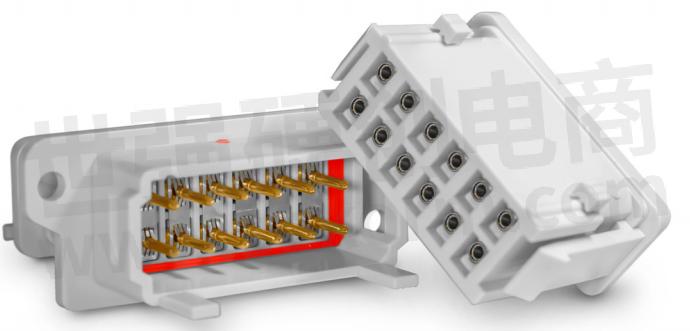

Environmentally-Sealed Rectangular Plastic Connectors Allow >500 Mating Cycles

Smiths Interconnectors' REP Series, multi-pole, sealed, plastic connectors, provides a quick and secure connection of embedded equipment across a wide range of industries, such as sensors, brakes, lighting, air conditioning, and communications found within industrial, rail, test, and measurement, automotive, public works and defense.

The connector uses the proven Hypertac® hyperboloid contact technology which guarantees excellent reliability, even under high levels of shock and vibration, and allows up to 500 mating cycles and a high current rating up to 18 A. The REP connector range offers two main versions: with crimp termination contacts for cable harness applications and with straight or bent termination contacts for PCB mount applications. Both versions are available in 3 layouts: 2, 6, and 12 ways. The REP Series comes with a shunt accessory enabling electrical derivation inside the connector for transmission of information to different locations.

Only one contact can be used for cross-section cables 0.5 mm² to 2.5 mm² (24-12 AWG) according to NFF 63-808 and EN 50-306 standards. No specific tool is required, with consequent reduction of the supply chain, maintenance, and cabling costs. Furthermore, for easy mounting, the connector includes polarized guides and provides several configurations: cable to cable, clips, front and back panel mount.

Connectors are available for delivery as a complete, tested pre-cabled solution according to customers' specifications.

Fig.1

●Features

■Compact, flexible design

▲ Standard insulators available in 2, 6, and 12-way configurations

▲Crimp, straight, and bent termination options

■Easy mounting and maintenance

▲ No specific tooling required for mounting

▲ One contact required for cross-section cables 0.50-2.50 mm2 (24-12 AWG) to NFF 63-808 and EN 50-306 standards

■High quality, integrated features

▲Overmoulded silicone grommet and interfacial seal delivers IP66 and IP67 protection

▲Vibration resistance to EN 61-373, Category 2 standards

▲Compliance with fire and smoke standards

▲Improved polarised guides

▲ Three coding devices: cable-to-cable, clip locking, and front and back panel mount

■Hypertac® contact technology

▲ 360° wiping action

▲ Low insertion/extraction forces

▲ Minimal contact resistance

●Benefits

■Optimized for use in rail and embedded applications

▲Space and weight savings

▲Qualified to ensure a high degree of safety

▲Able to accept a large panel of cables with the standard offering

Complete, tested pre-cabled solutions available to customer's exact specifications

■Fast and reliable connection

▲ Ensure failure-free performance in extremely demanding environments

▲Immunity to fretting caused by mating/unmating and shock and vibration

■Reduced cost of ownership

▲ Minimized supply chain, inventory, and maintenance costs

▲ Lowered cabling costs

■Superior performance

▲Hypertac® contacts ensure 30% higher current carrying capacity than contacts of the same size

- +1 Like

- Add to Favorites

Recommend

- Huafeng Smiths Interconnect lays out the high-end connector market and practices international standards Made in China

- Smiths Interconnect Acquires Reflex Photonics to Expand in High Speed Data Transmission Market

- How Smiths Interconnect Keeps The Medical World Connected

- Smiths Interconnect Expanded RF Filter Capability for European and Asian Markets

- Smiths Interconnect Expands into Burn-In Test Market with Acquisition of Plastronics

- Smiths Interconnect has announced New EasyREP connectors qualified to perform in rail and embedded applications

- Smiths Interconnect Deliver A New Highly Integrated Multi-channel Subsystem

- Smiths Interconnect Launches K-band Passive Components for Space Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.