Why Would The VC Radiator Been Famous?

As we all know, the traditional radiator has a simple structure, only the heat pipe, fin chip and the contact bottom surface made of copper and aluminum, and even the heat sink is just the base of fin chip and flat surface produced by the simplest aluminum extrusion process, but it is widely used. However, with the blooming of electronic products everywhere, the traditional radiator obviously can't keep up with the advanced pace, so under the condition of keeping the size unchanged, it is necessary to increase the heat dissipation power, and the VC soaking plate radiator has evolved and been born.

Principle of core temperature equalizing plate

Most of the existing soaking plates are copper substrates to facilitate welding, and the manufacturing method includes sintered structure. In the sintered structure, it is usually the surface of the copper shell, and the surface is formed with micro pores of Dry powder to slower condensation and reflow. However, its temperature of powder inside is high, which is time-consuming and laborious, and it is difficult to form whole monoliths. The consistency of sintered density effect can not be guaranteed, which leads to the performance difference and poor stability of vapor chamber. Therefore, how to avoid not using high-temperature sintering, reduce energy consumption and cost, and make the performance of vapor chamber more stable has become an urgent problem in this field.

Temperature equalizing plate technology is similar to heat pipe in principle, but its conduction mode is different. Heat pipe is one-dimensional linear heat conduction, while the heat in the vapor chamber of vacuum chamber is conducted on the two-dimensional surface, so the efficiency is higher. Specifically, the liquid at the bottom of the vacuum chamber absorbs the heat of the chip, evaporates and diffuses into the vacuum chamber, conducts the heat to the heat sink, then condenses into liquid, and then returns to the bottom. Similar to the evaporation and condensation process of refrigerator air conditioner, it circulates rapidly in the vacuum chamber, thus achieving higher heat dissipation efficiency. Temperature equalizing plate has been widely used in the heat dissipation field of electronic equipment. thermal plate uses the phase change process of working medium to achieve the purpose of effective heat transfer by absorbing and releasing latent heat. Moreover, it can effectively radiate heat with high-temperature "hot spots" and flatten it into a relatively uniform temperature field. How to make smaller, thinner and larger heat transfer temperature equalizing plates is of great significance to the field of electronic equipment heat dissipation.

Size-There is no limit in theory, but VC used for cooling electronic equipment rarely exceeds 300-400 mm in X and Y directions. Is a function of capillary structure and dissipated power. Sintered metal core is the most common type, with VC thickness between 2.5-4.0mm and minimum ultra-thin VC between 0.3-1.0 mm.

The ideal application of powerful VC is that the power density of heat source is more than 20 W/cm 2, but in fact many devices exceed 300 W/cm.

Protection-The surface finish most commonly used for heat pipes and VC is nickel plating, which has anti-corrosion and aesthetic effects.

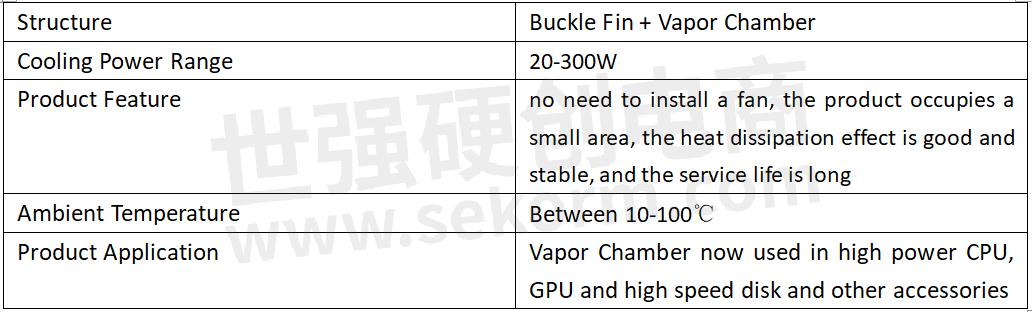

Operating temperature-Although VC can withstand many freezing/thawing cycles, their typical operating temperature range is between 1-100℃.

Pressure- VC is usually designed to withstand a pressure of 60psi before deformation. However, it can be up to 90psi.

Yythermal Product showcase:

VC Radiator has the natural advantage of minimum occupied area, thus breaking the idea that high-power radiator must adopt heat pipe, and laying the groundwork for the miniaturization structure of products in the future.

Yuanyang thermal energy welcomes all electronic and industrial enterprises to discuss the latest heat dissipation solutions together, in the spirit of mutual cooperation and mutual discussion, so that to promote the development of heat dissipation technology to a higher level, and solve the difficult problems caused by the high temperature and happened by increase of power that affect the use and performance of products for the progress of industrialization.

- +1 Like

- Add to Favorites

Recommend

- Which Type of Radiator is Generally Used in Computers?

- The Innovation for 4 heat Pipes CPU Radiator of High Cooling Performance 220W

- What is a Heat Sink Radiator: Unveiling the Secret of Efficient Heat Dissipation

- Is the Poor Performance of the Radiator a Problem with the Thermal Material?

- BOYD‘s Electric Vehicle Radiator Cooling Solution

- The Function of Cleanness for the Heat Sink and Fan

- Explaining the Thermal Design and Management

- The YYthermal Cooling Heat Sink as The Role for Cooling of 5G Communication Facilities

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.