Busbars for e-Aviation and High Altitude Applications

During the past years, electric automobiles have evolved from conceptual prototypes to a booming trend, overcoming great challenges on the way and occupying a growing portion of the automotive market. E-aircrafts are now in the concept phase, getting ready to take off. Several companies, ranging from small start-ups to large traditional aircraft manufacturers, are developing the next generation of flying machines.

Due to operating conditions, airborne components must comply with strict reliability and safety requirements. Atmospheric conditions at 8000 meters are very different than at sea level and not all components are inside the pressurized volumes of the aircraft. The low density of air at high altitudes has two main negative effects on electric systems. First, it reduces the cooling properties of air, and second, it decreases the dielectric strength of air, following the Paschen curve. Both phenomena have a strong influence on the performance and lifetime of insulated electrical conductors, such as laminated Busbars.

Laminated busbars represent the best solution for most solid-state power converters. In e-aircraft, it applies to the main inverter which powers the electric motors. ROGERS also offers ROLINX® CapLink Solutions that combine capacitors with ROLINX laminated busbars for low inductance and high-power density specially designed for high power inverters.

Rogers Corporation, ROLINX CapLink Solutions

Design Constraints for High Altitude Busbars

As air density decreases, so do its heat transfer capability. This is the reason why many electric components must be adapted and/or derated for operating altitudes above 2000 meters. ROLINX busbars are custom designed for each project and optimized based on operating conditions, including ambient air temperature and density.

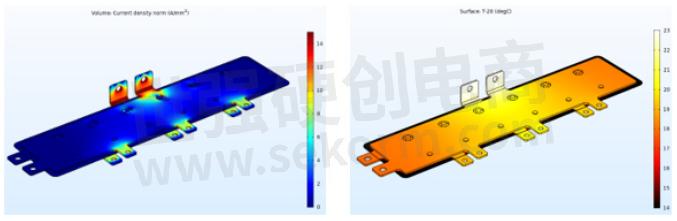

Rogers engineers' most powerful tools are their design experience and FEM simulations. In the case of high-altitude designs, FEM simulates the busbar's power dissipation and heat transfer to the environment at different ambient conditions. Once a 3D model is developed, its thermal response to outside temperatures and pressures can be studied virtually. This allows a quick iterative design that leads to the optimal conductor thickness while preventing overheating in all operating scenarios.

Rogers Corporation, ROLINX Busbars, FEM simulations

The FEM simulation above shows the current thermal distribution for a busbar model (on the left). For given ambient conditions (temperature, density, …) it is possible to obtain the busbar´s operating temperature, in order to, as necessary, optimize the design.

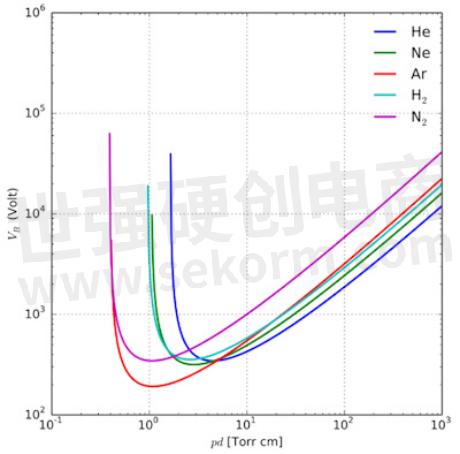

Another challenge for airborne electrical equipment is the decreasing dielectric strength of gases at lower pressures. This relationship was experimentally discovered by Friedrich Paschen who created the law that bears his name.

Paschen curves for different gases

In the case of air, the breakdown voltage is 3.1kV/mm at sea level pressure but decreases to 2.0 kV/mm at 0.5bar (pressure corresponding to 5500m) and even lower at higher altitudes. This phenomenon has two main implications:

If any transient voltage on the equipment becomes higher than the air´s breakdown voltage at the operating altitude, a flashover will occur if creepage and clearance distances are not respected. In the creation of a busbar at Rogers, this factor is considered and compensated during the design phase. In the prototype and manufacturing stages, all parts are electrically tested with a corrected voltage to account for this risk.

Film and rigid insulation are very sensitive to gaps in the interfaces, either between insulation layers or between the insulation and the conductors. These gaps are filled by air, which density depends on the operating altitude. These air bubbles can create a partial discharge. Partial discharge (PD) is defined in IEC60270 (section 3.1) as a “localized electrical discharge that only partially bridges the insulation between conductors […] Partial discharges are in general a consequence of local electrical stress concentrations in the insulation or on the surface of the insulation. Generally, such discharges appear as pulses having a duration of much less than 1 µs.” Although intermittent partial discharge does not affect the performance of the insulation, constant partial discharge higher than 10pC can degrade insulation properties and eventually lead to a short-circuit in the component. To achieve the maximum lifetime of ROLINX busbars without failures, each project is individually studied and designed, based on all environmental conditions, including high altitude effects on the insulation. Besides, partial discharge is measured in all busbars before delivery to verify that it keeps below 10pC, even at voltages higher than operating ones.

Conclusions

The evolution to cleaner transportation is pushing the development of e-aircrafts and is already a reality in the development phase. Operation at high altitude and other demanding specifications creates many challenges, pushing all electrical components a step further in performance. Operating at a high altitude with low air density has many implications on the design of laminated busbars. Technical requirements, ambient conditions, and physical phenomena are studied case by case at Rogers to deliver the safest and most optimized ROLINX busbar solution.

- +1 Like

- Add to Favorites

Recommend

- Simple and Compact Solar Busbars of FTG (Sub-brand of Amphenol-GIS)

- Amphenol-GIS Busbars for SPD Type 2 to Meet a Fast and Pre-assembled Wiring

- High Currents and a Secure Connection When there is Only a Little Space, Amphenol-GIS’s Fully Encapsulated Busbars are the Best Choice

- Eurovario busbars from FTG Easy and Fast Connecting, Rate Currents Up To 100 Amperes With A Voltage Of 690 Volts

- Inductance Optimization for Laminated Busbars

- Amphenol-GIS Offered Busbars for Arc Fault Detection Devices (AFDD)

- Rogers Corporation’s Power Electronics Solutions Group to Showcase curamik® Ceramic Substrates & ROLINX® Eco Busbars at the PCIM 2023

- ROLINX CapLink Solutions: Low Inductance Integrated Capacitor and DC Link Busbar Solution for e-Mobility

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.