ROLINX CapLink Solutions: Low Inductance Integrated Capacitor and DC Link Busbar Solution for e-Mobility

ROLINX Design and Development team is working with different global e-Mobility OEMs to develop the next-generation inverter system. The culmination of these new opportunities resulted in common requests from customers such as low inductance, reliability, flexible form factor, AEC-Q200 compliance, and of course the overall cost of ownership. Accordingly, ROGERS Corporation developed ROLINX CapLink: complete integration of a laminated Busbar and discrete film capacitor, which is one of the most optimized solutions for our customers.

Behind the scenes:

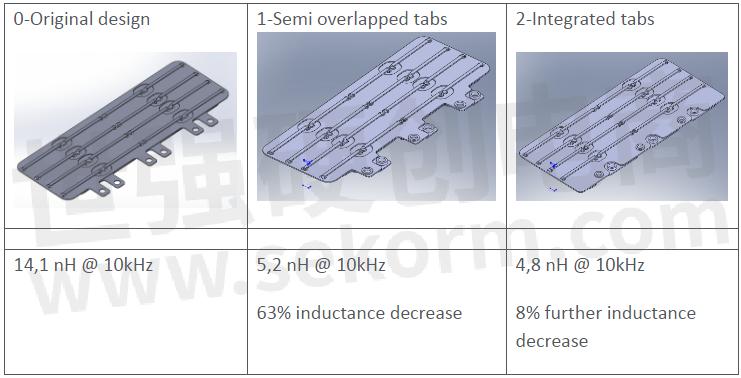

A Silicon Carbide (SiC) based power system is currently being developed to continue advancements in support of the e-Mobility market. Although SiC offers advantages at the system level, this new technology still cannot be fully exploited without an optimized design. Due to a higher switching frequency that requires dual optimization of the semiconductor device and the inverter topology to reduce an equivalent series inductance (ESL) and limit voltage overshoot at turn-off; DC link capacitors and interconnections can contribute significantly to the ESL. Whereas, standard capacitor banks provided by a capacitor manufacturer could offer inductance ranges between 20 to 30 nH. If a customer picks one of these capacitor banks and semiconductor devices, the inductance has been fixed, with no further room for improvement. ROLINX CapLink offers one-digit nH inductance and case-by-case optimization by different interconnections and architectures. Additionally, software simulation and specific instrument measurements could predict electrical performance during the design and prototype phase.

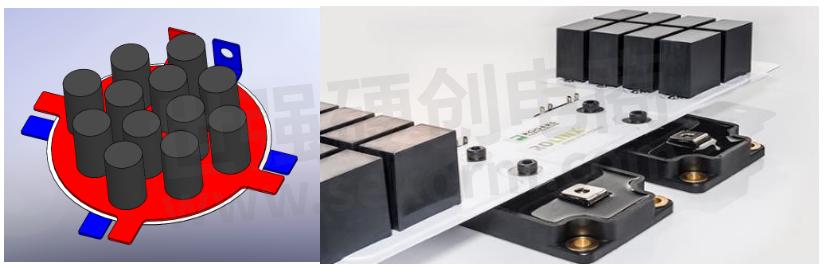

Given the narrow space of many e-Mobility applications, the shape is another key decision-influencing factor to optimize overall output. Unlike traditional capacitor banks with a standardized layout, ROLINX CapLink is more flexible when it comes to layout and outline. The busbar itself can range from rectangular to circular, which is beneficial for the housing of powertrain components by reducing the overall dimension of the inverter significantly.

A: Round Shape ROLINX CapLink B: Capacitor at two ends

Reliability is another challenge for the customer and supplier since almost all customers request AEC-Q200 compliance. In addition to the heavy cost burden to fully qualify, it takes around six to eight months to conduct testing. However, our ROLINX CapLink solution assembles qualified AEC-Q200 capacitors tested in the most critical AEC-Q200 requirements, including vibrations and extended thermal shock.

Customers can also benefit from ROLINX CapLink’s low overall cost of ownership. If one customer wants to design a customized capacitor bank by itself, the tooling investment could be a heavy burden. For example, the tooling for a 40X35X20 (L*W*H) mm injection molding plastic housing will cost somewhere between $10K~$15K and the MOQ is 10K. This alone can be difficult for a new start-up project. In addition, ROLINX CapLink can provide lower internal operations costs: when the busbar and capacitors are sourced separately it results in double the assembly and testing.

In the industry, soldering processes were developed for PCB assembly of components, thus requires a whole set of new technologies and abilities to perform capacitor connection to copper conductors thicker than 0.8mm. ROLINX team has developed state-of-the-art processes to create a solid and reliable connection, from laser welding to wave and robot soldering, which can handle copper thicknesses from 0.6 to 2mm. Furthermore, ROLINX profits from its experience in mechanical evaluation and electrical testing to inspect and test all finished ROLINX CapLink products for voltages up to 6kV. Therefore, allowing our customers to enjoy a one-stop service with fully functional and tested finished goods.

Overall, ROLINX CapLink appeals to each customer's individualized need by providing better electrical and mechanic performance, optimized design through tailor-made solutions, a low overall cost of ownership, and quick speed to market. Choosing the ROLINX team will deliver more than a capacitor and busbar, but a fully integrated solution. We call it 1+1>2.

- +1 Like

- Add to Favorites

Recommend

- Rogers Announces Acquisition of Silicone Engineering

- Rogers Corporation’s Power Electronics Solutions Group to Showcase curamik® Ceramic Substrates & ROLINX® Eco Busbars at the PCIM 2023

- Sekorm Became an Authorized Distributor of Rogers

- Rogers Corporation’s Curamik® Ceramic Substrates, Low Inductive ROLINX® Laminated Busbars Power Renewable Energy Sources

- Rogers Announces Termination of Merger Agreement with DuPont

- Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

- Rogers Expands Capabilities and Services with New Application Laboratory

- Rogers Corporation Announces Intention to Consolidate Manufacturing Facilities for RO3000® and RO4000® Product Lines

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.