QSFP-DD Optical Transceiver Thermal Interface Materials with Greater Density, Greater Heat

High-performance QSFP-DD optical modules must use thermal interface materials to help dissipate heat efficiently and effectively to ensure the optimum operating performance, reliability, and dependability of the high-speed transceiver.

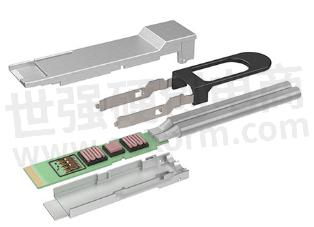

The introduction of QSFP-DD, or Quad Small Form Factor Pluggable Double Density optical modules, has now doubled the number of high-speed electrical interfaces that the module supports compared with a standard QSFP28 module.

Greater density, greater heat

QSFP-DD modules are the newest standard in high-speed pluggable connectors, as they are the smallest form factor 400 G/s transceivers, offering the highest bandwidth density while leveraging the backward compatibility to lower-speed QSFP pluggable modules and cables. Highly integrated and advanced PAM-4 DSP chips, externally modulated laser (EML) diodes, and GaAs laser diodes enable the 400 G/s performance, yet these ICs come with significant thermal issues.

Power loads of up to 25W require significant considerations for heat dissipation, including the application of thermal interface materials.

The goal of a system thermal design is to remove the heat from the module case to ensure that the internal components in the module stay within operating temperature ranges to ensure optimal performance and reliability.

The role of thermal interface materials (TIMs)

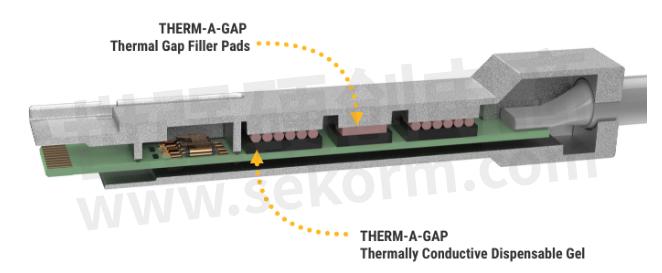

Thermal interface materials such as thermally conductive gap filler pads, thermal greases, and dispensed thermal gels improve heat dissipation by filling minute air gaps and voids and by being dispensed or in contact with heat-generating chipsets. Maximizing the contact area of the heatsink to the module lowers the thermal resistance and improves the system’s ability to cool the module.

Types of TIMs available

High power thermal gels, such as Parker Chomerics THERM-A-GAP GEL 75, with 7.5 W/m-K thermal conductivity, as well as high-performance single-component thermal greases such as THERM-A-GAP GEL 8010 3 W/m-K, are typically robotically dispensed for high volume applications such as optical modules.

Robotically dispensing thermal interface material can dramatically reduce costs, save valuable time, and greatly improve the overall performance of the QSFP-DD module. Thermal gap filler pads can be die-cut into exact shapes to help dissipate heat from any heat-generating component. Thermal gap filler pads provide a soft and effective method of heat dissipation as well as helping to reduce vibration stress for shock dampening.

A TIM for every design; yes, even yours

Whatever your design is, be it a stacked card cage, or belly-to-belly, the thermal interface between the optical cable connector module and the heatsink attached to the outer case/cage is important to your design.

With speeds of 400 G/s being introduced now and 800 G/s on the near horizon, you must also consider the thermal heat dissipation needs of not only the module itself but the interface connection on the PCB, as well as at the rack unit or cabinet level.

Cabinets featuring 40U to 46U racks require immense thermal heat dispersion featuring both active and passive cooling technologies. Higher data transfer speeds, low latency, and constant availability require more computing power, which in turn means higher power densities per rack.

- +1 Like

- Add to Favorites

Recommend

- On the Cutting Edge: How Parker Chomerics Helps SpaceX Soar

- Sekorm Became an Authorized Distributor of Parker Chomerics

- 5.2W/m-K High Reliability, Fully Cured, Dispensable Thermal Gel from Parker Chomerics

- Why Do 400G Optical Transceiver Prefer QSFP-DD?

- Coherent Announces General Availability of 800G ZR/ZR+ in a QSFP-DD Form Factor

- Advanced Battery Energy Storage Systems (BESS) Solutions: Parker Chomerics 6.0W/m-K THERM-A-FORM CIP 60

- PARKER CHOMERICS New Electrically Conductive Sealant CHO-BOND 1018 Offers Unique Combination: Galvanic Compatibility to Aluminium and Fluid/Fuel Resistance

- Manufacturers of Thermal Interface Solutions, Tools, And Assembly Aids for PCS——thermal grizzly

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.