The Evolution of the Power Wiring System: Advanced Automated Driving Prompts New Safety Requirements

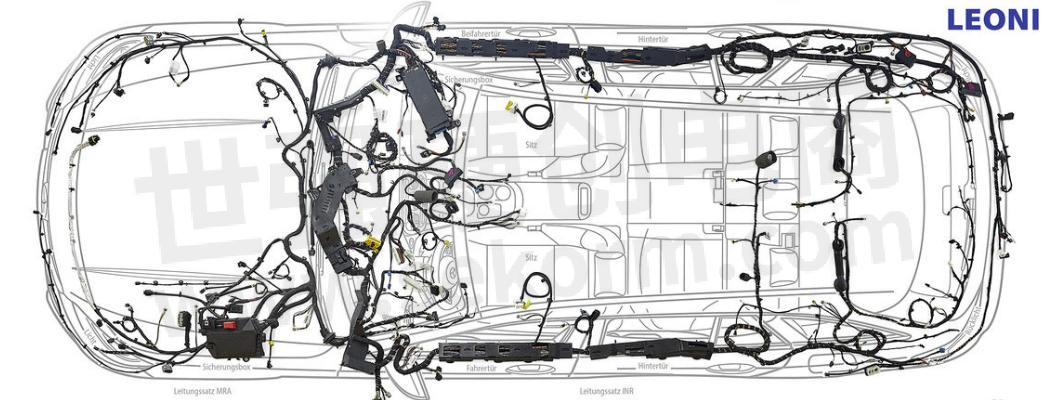

Developments in the automotive industry are currently advancing at a rapid pace. Legal regulations, such as CO2 requirements, are changing; new driving and comfort functions are being added; and existing functions, some of which are still mechanical, are being expanded and increasingly electrified. As a central infrastructure element, the wiring system is the backbone of a vehicle. This makes it worthy of special focus in further automotive development.

The creation and refinement of new vehicle functions have led to a reevaluation of the wiring system. Existing components are being eliminated and new ones added (e.g., modern battery technologies or the incorporation of DC-DC converters in place of conventional generators).

Sample illustration of electrical sensors for implementing new customer functions

This has generated enormous interest in the question of how to deal with changes in the wiring system. Are currently valid "proven in use" arguments still applicable? How will newly implemented wiring system architectures and those currently in development influence existing requirements? What mechanisms will be needed to meet the changed requirements? These and many other questions can be successfully resolved only through detailed analysis and a very good understanding of the overall system.

Consequences for the wiring system include increasing complexity in cabling and the use of new power distribution components that enable the system to respond to the changed (safety) requirements. New or reevaluated safety concepts are needed at this level as well. The ability to implement functional safety requirements is a decisive factor in the evolution and refinement of wiring systems.

Modern vehicles already contain functions that place certain demands on power supply availability. Nowadays, for example, lights, wipers, brakes, or steering assistance are classified as safety-relevant.

The ISO 26262:2018 standard serves as the basis for ensuring safety functions. This standard also establishes clear requirements for the definition and implementation of safety-relevant driving functions. Among other things, it specifies that non-safety-relevant driving functions must not have any influence on safety-relevant functions. If a negative influence cannot be entirely prevented, mechanisms must be provided to ensure that there are no unintended effects.

If we now consider automated driving functions, the respective SAE level of the vehicle and the application (operational design domain) results in significantly increased availability requirements for certain functions. For example, safe operation is sometimes necessary even after an initial fault has occurred. Depending on the architecture and overall concept, these requirements can or must be transferred to the power wiring system.

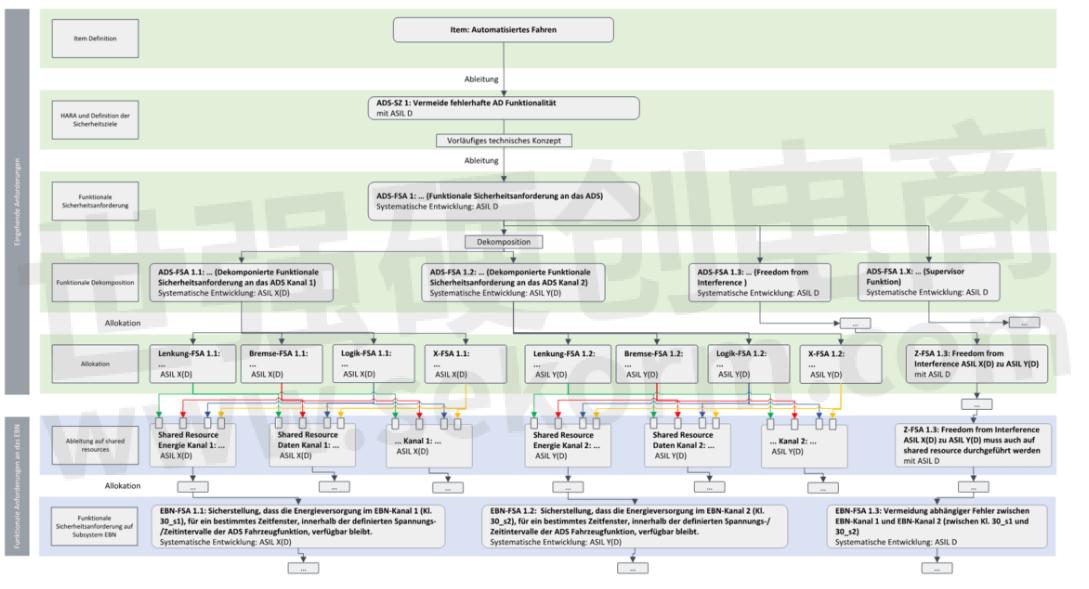

The VDA 450 project group "Power Wiring Systems for Highly Automated Driving," which includes OEMs and suppliers, was established to develop a common understanding of the coming challenges and new requirements that will have to be fulfilled. The aim is to develop a generic safety concept, derive safety requirements, and allocate them to system elements.

Conventional wiring system architecture. The question: Can this implement all of the new driving functions in the vehicle?

As an example, a hierarchical procedure for deriving requirements and allocating them to the shared resource of the wiring system could appear as shown below.

Sample requirement derivation up to the components of the power wiring system

Each of the active and passive components in the wiring system must meet these requirements. Safety considerations must therefore take into account the failure modes for random and systematic faults in these components.

To prevent systematic failures, the requirements of ISO 26262:2018 must be met and failure modes in the design, product development, and manufacturing processes must be verifiably identified and included.

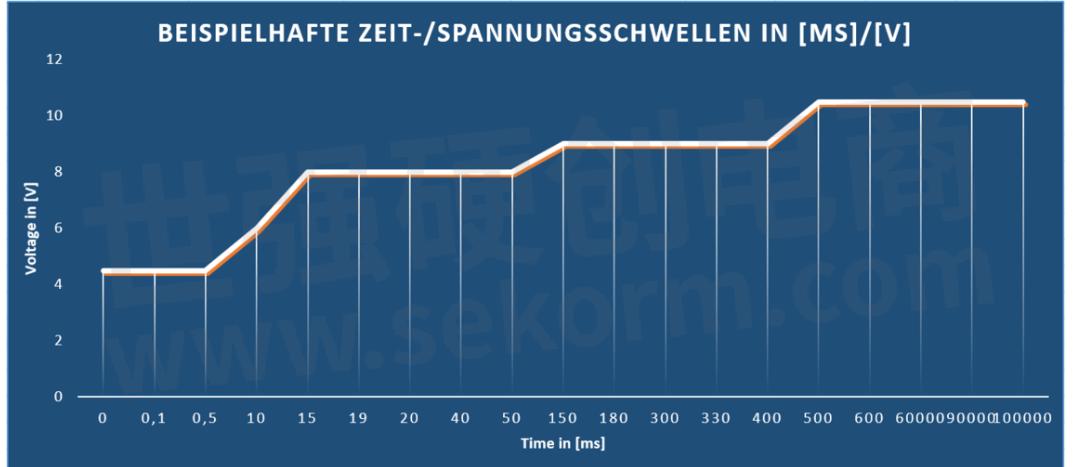

One of the best-known failures that can have a direct impact on other safety requirements is the electrical short-circuit of a wire or component to vehicle ground. This can produce a critical Undervoltage in the entire wiring system for a certain period of time, which could lead to the functional failure of all safety-relevant components. Many vehicles have state-of-the-art fuses to protect wiring from fire or similar consequences. Problems can arise, however, if the fuse does not blow quickly enough or if the wiring system is not appropriately designed to prevent the critical voltage drop. If this situation occurs during an energy-intensive driving maneuver, one extreme result could be a total failure of the vehicle's electrical system, with correspondingly serious consequences. Whether such a scenario can occur depends on many factors and must be evaluated based on the vehicle architecture.

Time/voltage diagram for representing operating limits of components in the 12V wiring system

Some vehicle manufacturers install semiconductors that can prevent the flow of energy to a short circuit within milliseconds in the event of such a well-known failure, thereby maintaining the stability of the vehicle’s electrical system. Additional mechanisms such as these make it easier to implement zonal architectures since they can locally prevent safety-relevant components from influencing each other and non-safety-relevant components from influencing safety-relevant components. These additional mechanisms increase costs, however, and necessitate the reevaluation of existing "proven-in-use" arguments. The question is whether such mechanisms are necessary or whether conventional solutions could continue to perform this task reliably.

LEONI also serves as a system partner to its customers for issues relating to the evolution of the wiring system and provides valuable support from the concept phase to serial production.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.