Predict Ssd Lifespan by Understanding Endurance Specification

As Solid state drives (SSDs) become more and more prevalent, it is important to understand that not all SSDs are the same.Get to know some of the most common specifications to help you decide which SSD to purchase:

SSD States and the Passage of Time

Due to the unique nature of flash memory, SSD performance can vary with the passage of time. An SSD typically goes through the following states, and performance at each state is different.

Fresh-Out-of-Box (FOB)

This state refers to the condition of an unused SSD, when it is first received from the manufacturer. Few or no program/erase (P/E) cycles have been applied. At this state, the drive is empty and can therefore perform write operations without having to delete entire blocks first. The new drive will write faster, and performance is naturally at its highest.

Steady State

In this condition, the SSD has undergone several program/erase cycles and performance settles over time to a lower, more stable range. To accurately judge the P/E cycles of an SSD, a technique called pre-conditioning is used. This involves performing a series of writes in a fixed pattern to simulate the drive’s steady state.

Endurance and Reliability Specifications

Flash endurance specifications can help "predict" the longevity of an SSD. Endurance is typically measured in the following ways:

TBW

TBW or terabytes written, measures the total amount of data that could be written to the SSD during its life span.

TBW = (Physical Capacity in GB x P/E Cycles) / WAF, or write amplification factor, as defined in JESD219A Below are sample computations with assumed capacities, P/E cycles and WAF values. These are provided for illustration purposes only.

Examples:

128 GB triple level cell (TLC) SSD with assumed 3,000 P/E Cycles and WAF of 3: (128 x 3,000) / 3 = 128,000 GB or 128 TB

The TBW computation for a TLC SSD in pSLC mode is slightly different. The physical capacity must first be divided into three, as it functions as single level cell (SLC) flash by storing only 1 bit per cell. 256 GB pSLC SSD with assumed 40,000 P/E Cycles and WAF of 3:

256 GB / 3 = 85.3 GB, rounded off to 85 GB Physical Capacity (85 x 40,000) / 3 = 1,133,333 GB or 1,133 TB

DWPD

DWPD or drive writes per day measures the number of times you could overwrite the entire drive each day within its warranty period. DWPD may be computed as follows:

DWPD = TBW in GB / Warranty Period / 365 / User Capacity In this formula, it is important to note that “User Capacity” is the usable capacity after overprovisioned space is deducted from the total physical capacity.

Overprovisioning space may vary by product and project. Below are sample computations with assumed TBW values derived from previous examples, warranty period, and user capacities. Again, these are provided for illustration purposes only.

Examples:

128 GB TLC SSD with assumed 7% overprovisioning, 128,000 GB TBW, and 5-year warranty: 128,000 / 5 / 365 / 120 = 0.58 This means that the entire capacity of 128 GB can be written to .58 times each day during the 5-year warranty period.256 GB pSLC SSD with assumed 1,133,333 GB TBW, 5-year warranty and 80 GB user capacity: 1,133,333 / 5 /365 / 80 = 7.76

This means that the SSD can be written to 7.76 times each day during the 5-year warranty period.

P/E Cycle

P/E Cycle reflects the lifetime of an SSD based on the number of P/E cycles the NAND can endure. Each time a block is written to and erased, that is one cycle. This is important because blocks can be written to for a finite number of times, beyond which they cannot write new data anymore.

ATP employs several mechanisms to prolong SSD life. Advanced Wear Leveling, for example, evens the erase count of all blocks to prevent overusing and thereby prematurely wearing out heavily used blocks. Wear leveling the entire SSD prolongs the life expectancy of the storage device.

MTBF

MTBF or mean time between failures is calculated as the average period of time that the storage device is operational until it fails. It is expressed in hours, and the higher the number, the more reliable the storage device is. ATP's industrial SSDs are rated for millions of hours, which could translate to hundreds of years. An MTBF of 2,000,000 for example, means that the SSD can operate reliably for over 228 years running 24 hours a day.

Data Retention

refers to the length of time that the storage device is able to keep data without being corrupted. A sample specification of "5 years with 10% P/E cycles @ 55 °C" means an SSD used up to 10% of its P/E cycle rating can guarantee data integrity up to 5 years after being powered down and then stored at 55 °C.

Thermal Specifications

Operating temperature refers to the temperature at which the device can perform effectively, based on its workload, function, application, and environmental conditions. SSDs are generally rated according to the following temperature grades.

Performance Specifications

The term storage “Performance” generally refers to “how well the SSD functions when accessing, retrieving or saving data.”

(An Introduction to Solid State Drive Performance, SNIA. Evaluation and Test. August 2013)

Read/Write Speeds measure how fast it takes to read from or open something and write to or save something on a storage device within a specific period of time. Typically, two types of speed are measured, usually in seconds.

Sequential read/write measures how fast the SSD can read and write big chunks of data to a specific location of the drive. SSDs can typically read and write single, large files faster than random, smaller files.

Random read/write measures how fast the SSD can read and write small-size data (typically 4 KB) in random areas of the drive. This is considered to be a more realistic gauge of performance to simulate real scenarios. 4KB random read/write specifications are listed as IOPS (Input/Output Operations Per Second), pronounced as EYE-OPS.

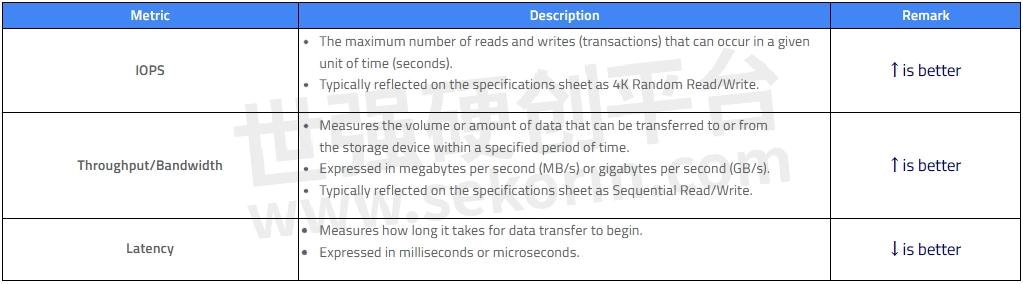

SNIA lists three fundamental metrics, each one representing a performance dimension.

Table 1. Three most fundamental, commonly advertised performance metrics.

How Relevant are these Metrics?

People hate to wait. So in an era when almost anything can be had in an instant, an organization that cannot deliver rapid response times will bear the brunt of dissatisfied users and customers. In most data storage infrastructures, improving storage performance is always a top priority, with an overwhelming emphasis on higher IOPS.

Typically, IOPS and throughput or bandwidth will give you an indication of the rate at which the storage device can read or write data. Both are important, depending on what type of data is being processed. When working with large files such as videos, high throughput means you don't have to wait a long time to render high-definition content. On the other hand, if you are working with databases that require many random small transfers, you will need a device with high IOPS.

Latency can help put IOPS and throughput in perspective. Latency is defined as the "delay" between the time a request is issued and the time the request starts to be carried out. Devices optimized for low latency naturally gives the user the feeling of speed because there is less waiting. If latency is high in I/O-intensive workloads, even short wait times compounded many times over can seriously affect the user experience.

When comparing the specifications of different SSDs, the key is not to search for the highest numbers. It is important to choose the device that will yield the best return on investment (ROI), and that will require understanding the SSD’s intended use, potential workloads, and testing methodologies employed.

Conclusion

ATP offers flash storage products in different capacities and form factors with specifications to meet the diverse and rigorous requirements of industrial applications. Built for different workloads, usage scenarios, and operating environments, ATP industrial SSDs are guaranteed to deliver outstanding performance, rugged durability, and many years of reliable performance. With over 25 years of expertise in the manufacture of industrial memory and storage products, ATP is dedicated to fulfilling customer needs for their mission-critical applications.

- +1 Like

- Add to Favorites

Recommend

- SMART’s DuraFlash N200 SATA 2.5” Solid State Drives Provide Economic Yet Highly Reliable Mass Storage

- SMART’s DuraFlash ME2 SATA 2.5” Solid State Drives Offer Highly Reliable Mass Storage with 3D NAND Technology

- SMART’s DuraFlash CS210 SATA 2.5” Solid State Drives are Designed for General-purpose Industrial Applications

- SMART‘s DuraFlash R800 SATA M.2 2280 Solid State Drives,available in both Commercial and Industrial Temperature Ranges

- ATP Customizes PowerProtector Firmware in Solid State Drives(SSDs) for a Leading Aerospace Company

- T5PF 2.5”SATA Solid State Drives With FIPS 140-2 Compliance Deliver High Performance

- T5PFLC 2.5″ and M.2 2280 SATA Solid State Drives (SSDs) Come Equipped with FIPS 140-2 Encryption Capabilities

- What Is a Semi-Solid State Battery?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.