Chroma 11210 Battery Cell Insulation Tester Prevents Li-ion Batteries from Catching Fire with Correct Jelly Roll Insulation Test

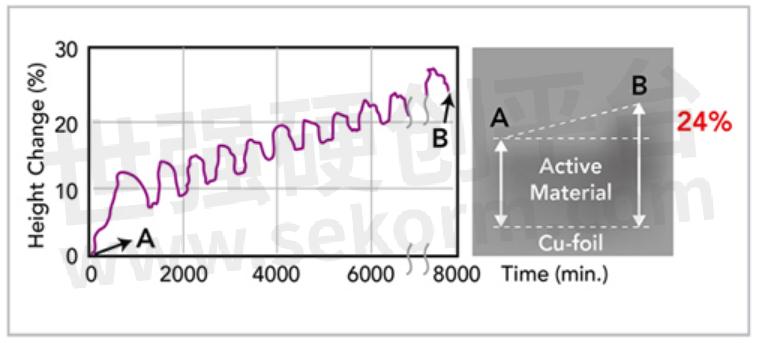

Most fire accidents in various products using lithium-ion batteries, including electric vehicles, occur while charging. The main reason for this is that the negative electrode material (graphite or mixed silicon) continues to inflate (Figure 1) after repeated charging cycles, shortening the distance between the positive and negative electrodes. This results in the effective distance between these electrodes becoming shorter than the original design due to electrode burrs or metal particles, increasing the risk of an internal short circuit.

Figure 1 Height changes of graphite anode material during charging and discharging

of a lithium-ion battery(Furukawa Electric Review, No. 134 2015-1)

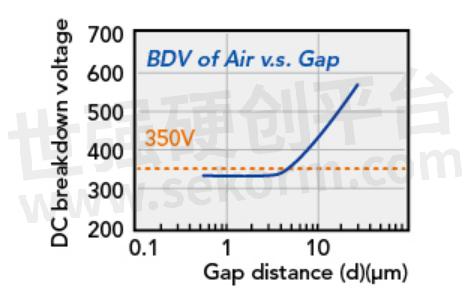

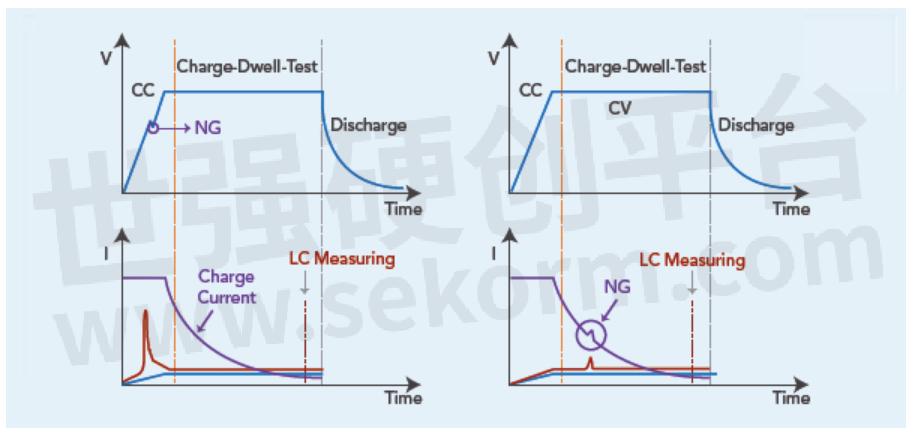

Therefore, from a fire protection perspective, insulation tests of lithium-ion battery cells should check the distance between electrodes, rather than measure the insulation resistance. From the air breakdown voltage v.s. distance data (Figure 2), we can see that, even if the gap distance is as short as several μm, the breakdown voltage is higher than 350V, so the insulation withstand voltage test should be conducted at a voltage higher than 350V. Testing for the occurrence of breakdown or flashover enables an effective assessment of whether the insulation distance is sufficient (Figure 3).

Figure 2 Relationship between air breakdown voltage and distance

Figure 3 Electrical flashover during testing

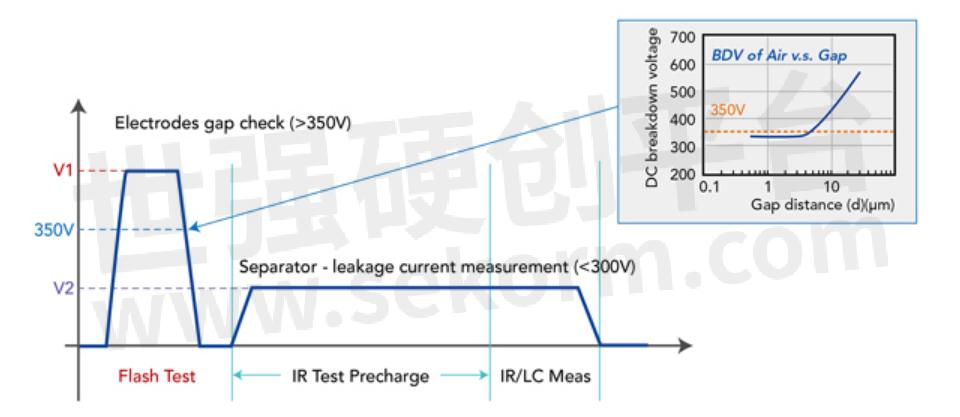

Besides fires, another hazard to be considered is excessive self-discharge caused by conductive impurities (leakage current) inside the separator. The testing voltage of this part need not be too high, and it takes a long time to wait for the real leakage current to become apparent. CHROMA 11210's +Flash test function provides two-stage intermittent high and low voltage tests, which allow customization of timing sequence, sampling integration time, measurement ranges and defective judgment conditions, fully meeting the requirements of these two aspects of insulation quality inspection of lithium-ion battery cells.

(Figure 4) Application of Chroma 11210 + Flash Test function in insulation quality inspection of Li-ion Batteries

Chroma 11210 battery cell insulation tester uses unique electrical flashover detection technology and its built-in +Flash test function for lithium-ion batteries (dry cells) to detect the sufficiency of the effective insulation distance before electrolyte filling and to detect any abnormal electronic leakage current. This effectively reduces the risk of lithium-ion battery fires and prevents products with potential insulation defects from entering the next production stage or even the end market.

- +1 Like

- Add to Favorites

Recommend

- Chroma Regenerative Test Solutions Accelerate Net-Zero Transition

- Chroma Launches Next-Generation High-Performance Power IC Test Platform Chroma 3650-S2 Equipped with up to 768 pins, 200Mbps data rate

- Chroma ATE Showcases Latest Test Solutions at TAITRONICS 2023

- Chroma ATE Presents Electric Vehicle Test Solutions for a Sustainable Future

- Chroma ATE Showcases Advanced Test Technology to Propel the AI Revolution at SEMICON Taiwan 2023

- Sekorm Became an Official Authorized Distributor of Chroma

- Chroma ATE Inc. Featured in Forbes Asia‘s Best Under A Billion 2023, Showcasing Consistent Top- and Bottom-Line Growth

- 8610 Battery Pack Integrated Testbed for Testing New Energy Vehicle Battery Systems and Subparts | Chroma

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.